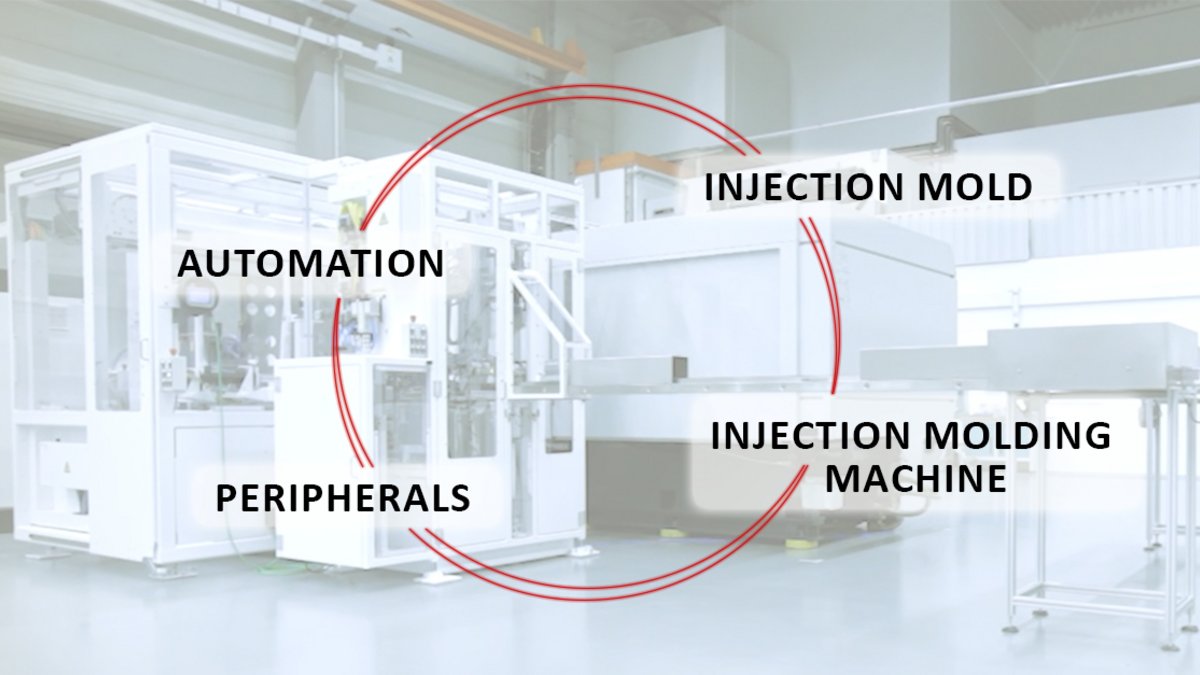

Over the years, we have gained more and more know-how in the field of injection molding, strengthened our expertise and can therefore combine our knowledge and understanding of injection molding and automation at the Hallbergmoos site. This forms the base to act as a turnkey provider for the complete production line with injection molding machine, mold and peripherals – with overall responsibility from planning, implementation and production through to service.

For you it means having only one contact and one supplier for your entire project. You get a full solution and can focus on the essential: your customers.

In a first step, we analyze your requirements, advise you on the optimum overall solution, considering all influencing factors and potential preferred suppliers, and choose the best matching technologies and partners from our large network.

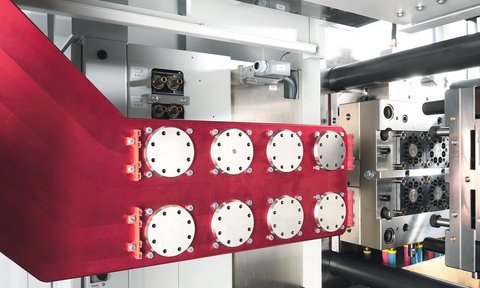

After selection, we take care of procurement, prototype development and mold validation.

In addition to the design, assembly and commissioning of our own automation, we also are in charge of the installation and commissioning of all other components, including project coordination, logistics, data management, certification, qualification and documentation.

Advantages of the all-round carefree package:

- Reduction of complexity and risk

- Saves resources and time for customers by eliminating the need to search for, select, negotiate with and coordinate various providers

- Quality optimization and reduction of workload through simpler and better coordination

- More cost-effective offers due to package price

- Proven process technology

Get in touch with our experts

BBS Automation Hallbergmoos GmbH

Would you like to contact BBS Automation online?

Then use our online contact form!

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!