A Maximum of Reliability and Modularity

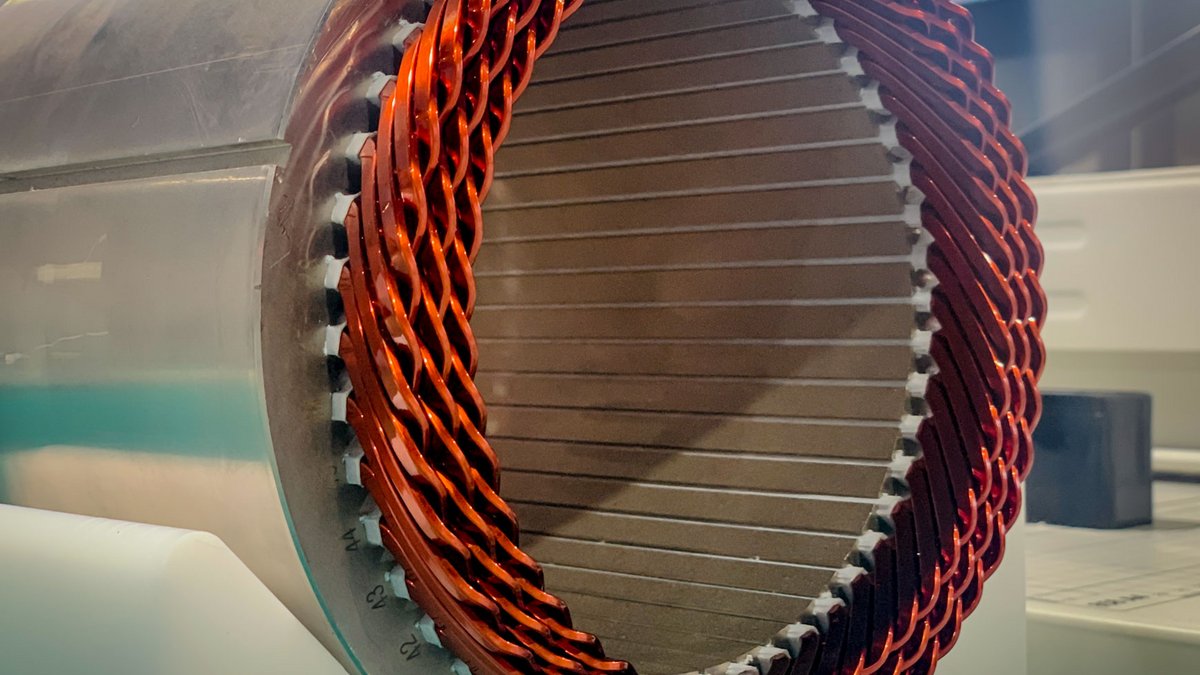

Stators with hairpin technology are used in connection with the manufacture of electric drive motors (traction motors) for electric vehicles, both passenger cars and commercial vehicles. This technology is becoming increasingly important as the transport revolution progresses and more and more vehicles get electrified in almost all countries.

Hairpin technology belongs to the winding processes, although no conventional coils of copper wire are manufactured. Rather, copper bars are used, which are inserted into the stator stack and consist of enameled copper wire with a layer of lacquer. The U-shape of these plug-in coils is reminiscent of classic hairpins. Due to the flat cross-section of the copper wire, the slot fill rate of the hairpin can be higher, which means better power density. In addition, the high fill rate also results in better thermal performance and NVH.

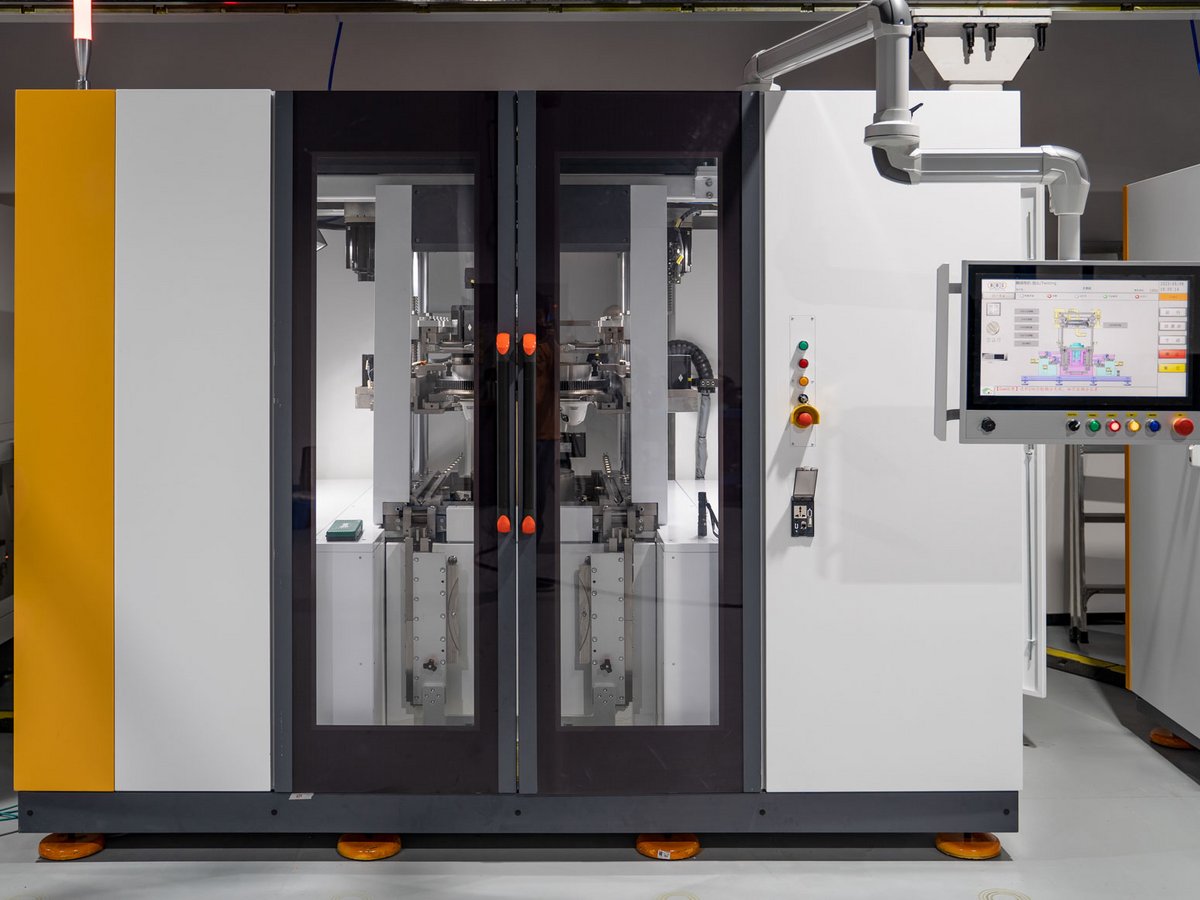

The BBS Automation production machines for the manufacture of hairpin stators are characterized by a specific structure, they are designed for the production of large quantities. They represent the entire process chain:

- Wire forming

- Paper insertion

- Wires insertion

- Widen

- Twisting

- Welding, interconnection

The individual process steps run in individual process cells. These are available as standalone or complete solutions.

See our winding technology section for roving, needle and linear winding technology.

Facts about Hairpin Technology

- Designed for the production of large quantities

- Available as standalone or complete solutions

- Machines for high performance and demands

- Low cycle times and fast changeover times

- Stability, precision and adaptability

Our Advantages

- Wide experience and various product range

- Global footprint of BBS

- Multilingualism of employees

- Tailored, customer-oriented solutions

- Optimized build times with 100% monitoring, reliability, quality

- Global project management and service support

- A key account team conducts each project

Features

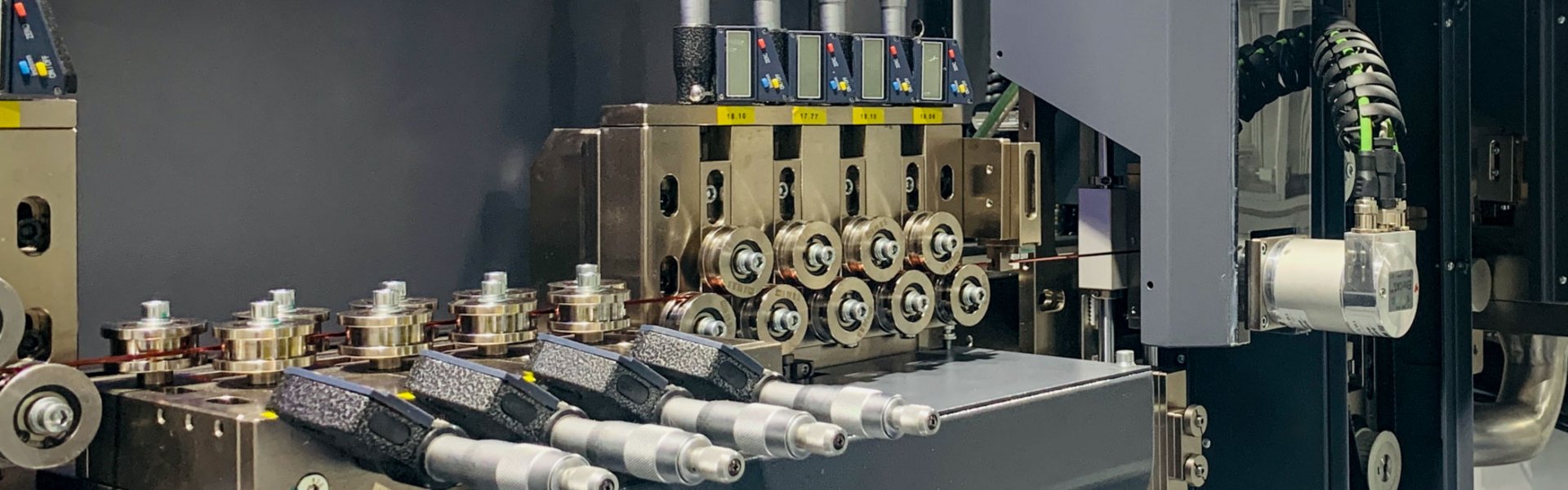

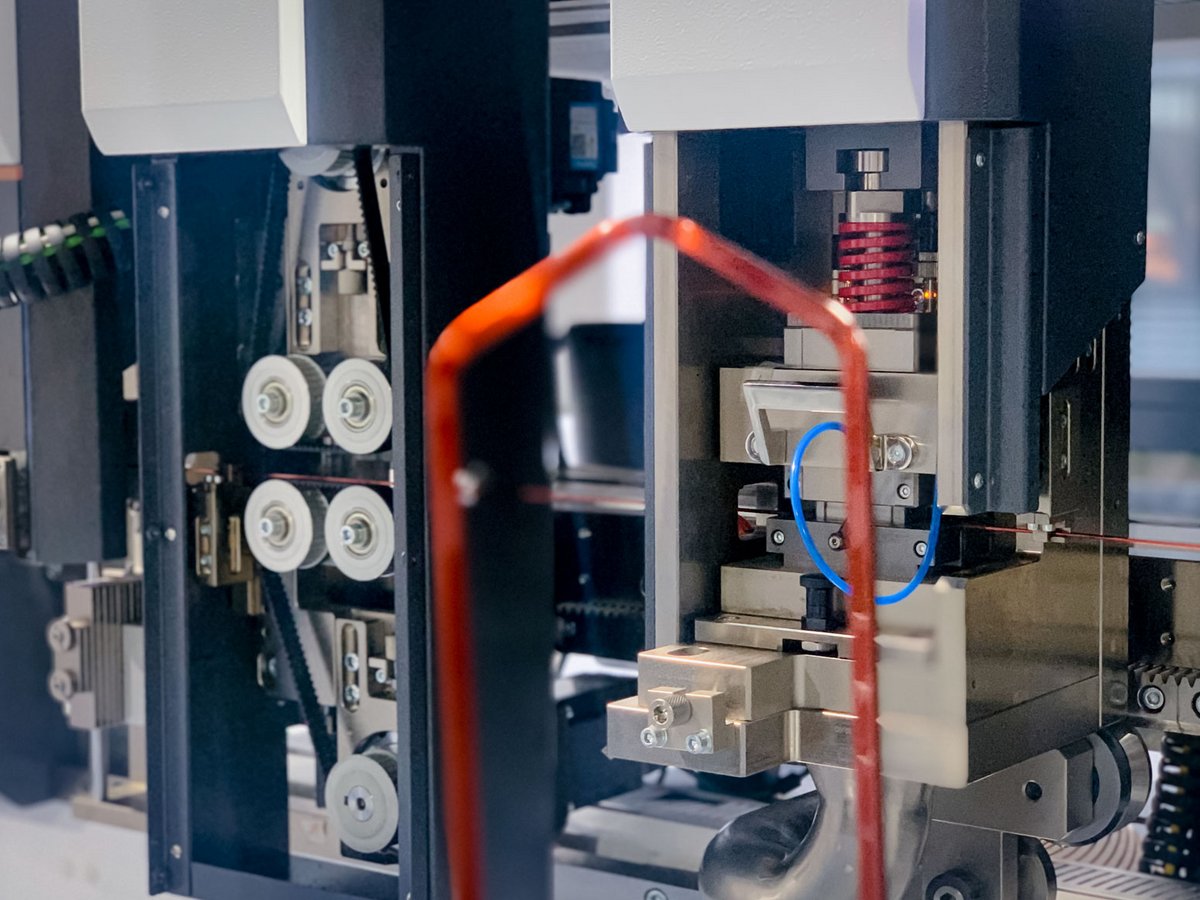

Wire forming

- Cycle time 1.5s/pc

- Online type change

- Online insulation test

- Non-stope replacement of the wire reel

Paper Insertion

- Cycle time 1.3s/groove

- Parallel loading and unloading

- Optional dual-channel process to meet cycle time requirements of up to 96 slots

- Electronic cam control, compatible with large laminating height

Wires insertion

- Cycle time 1.5s/pc

- Compatible with B/0 geometry

- Vision-based monitoring of the insertion process

- Quick replacement of the wire cup

Widen

- Synchronous expansion of up to 16 slots

- Compatible with non-concentric wire widening

- 3D vision-assisted control after widening

- Quick change of the iris tool

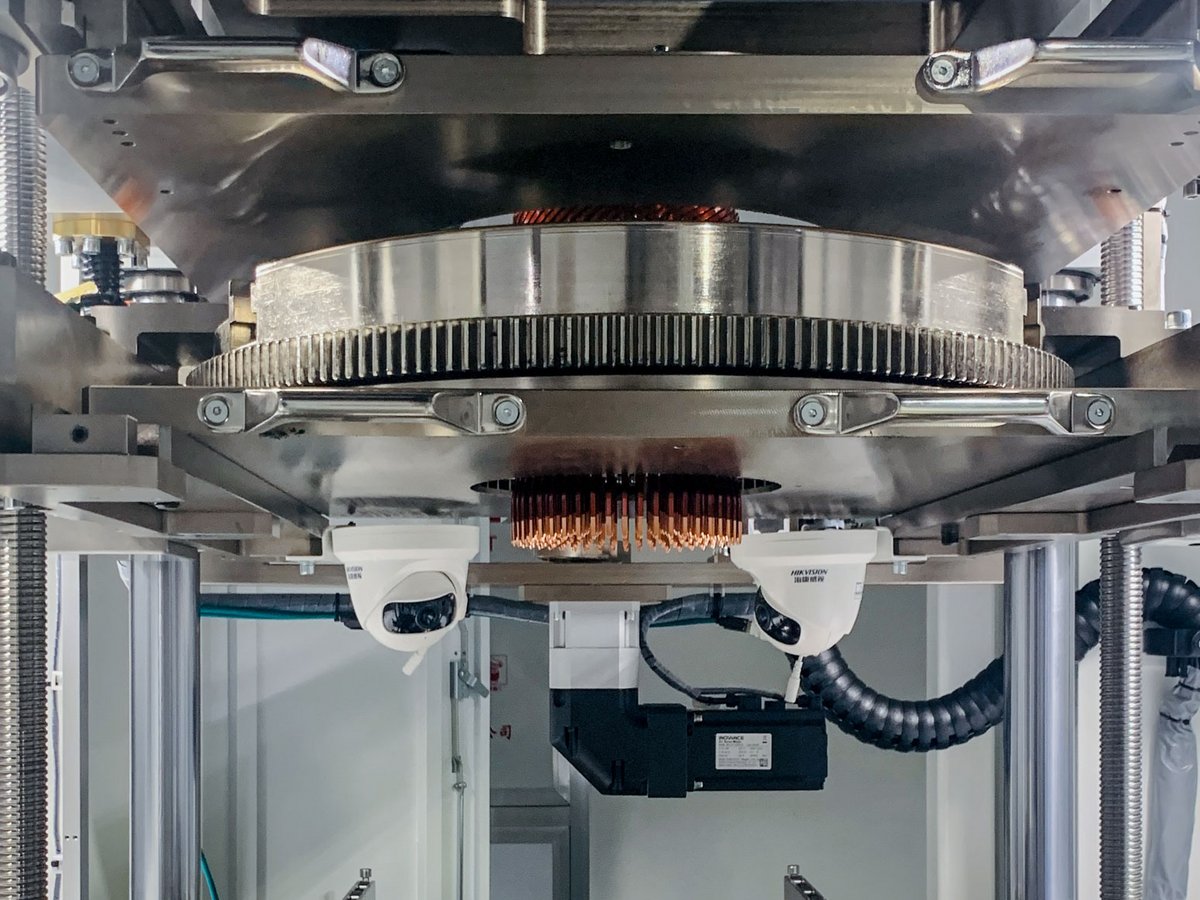

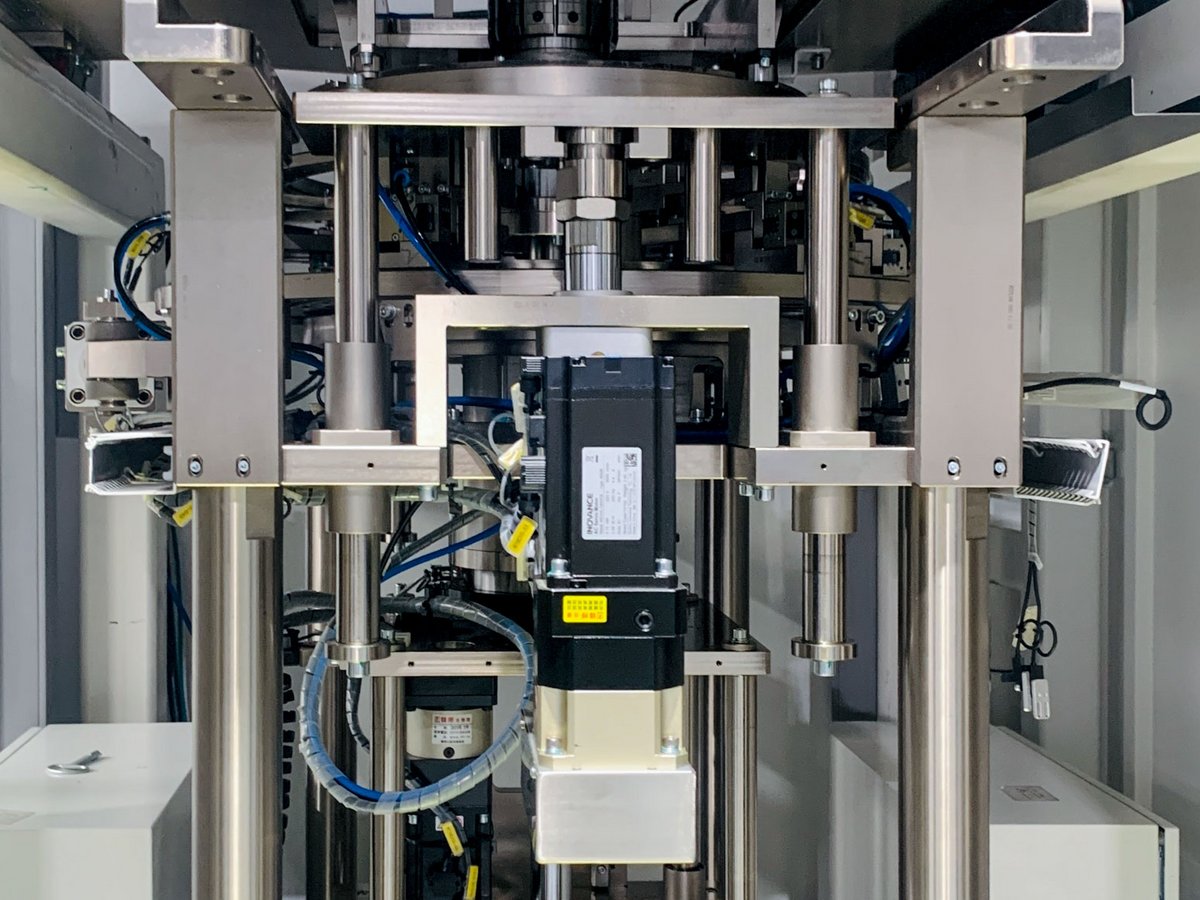

Twisting

- Machine cycle time < 60s

- Drive structure with torque multiplier

- Great adaptability to the insertion mold

- Analysis of the closed loop for the Z - Θ compensation curve.

- Extremely fast changeover of the twist mold

Welding

- High stability: marble platform

- High precision: linear motor

- High adaptability: 2D + 3D detection before welding

- High quality: quality control during and after welding

Get in touch with our experts

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB