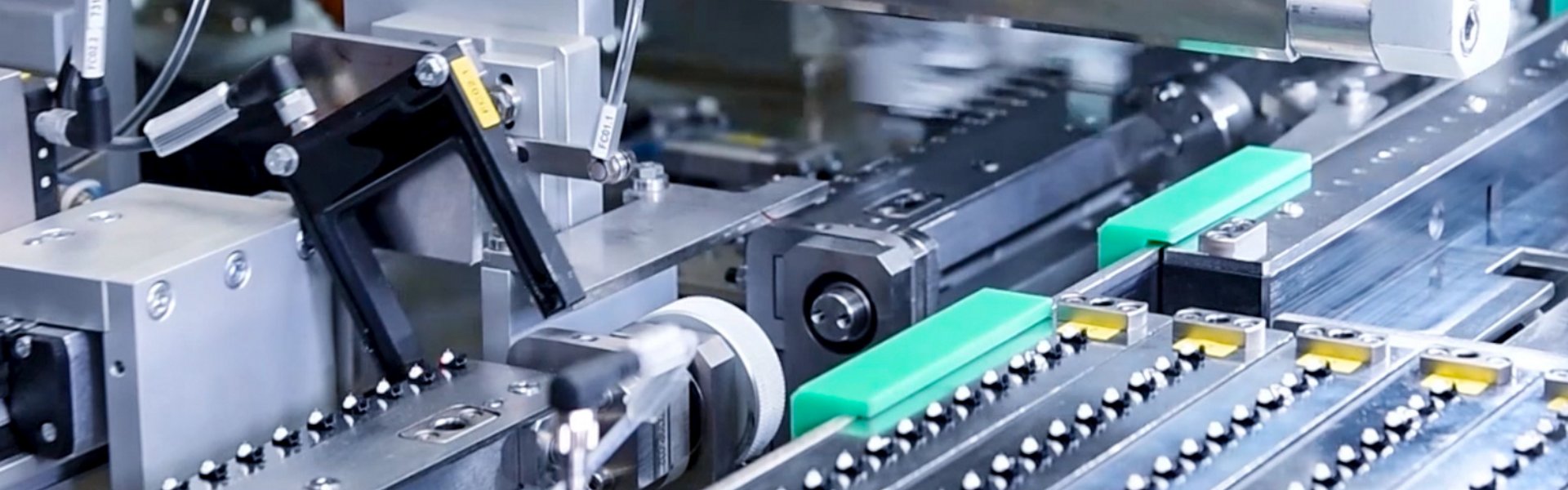

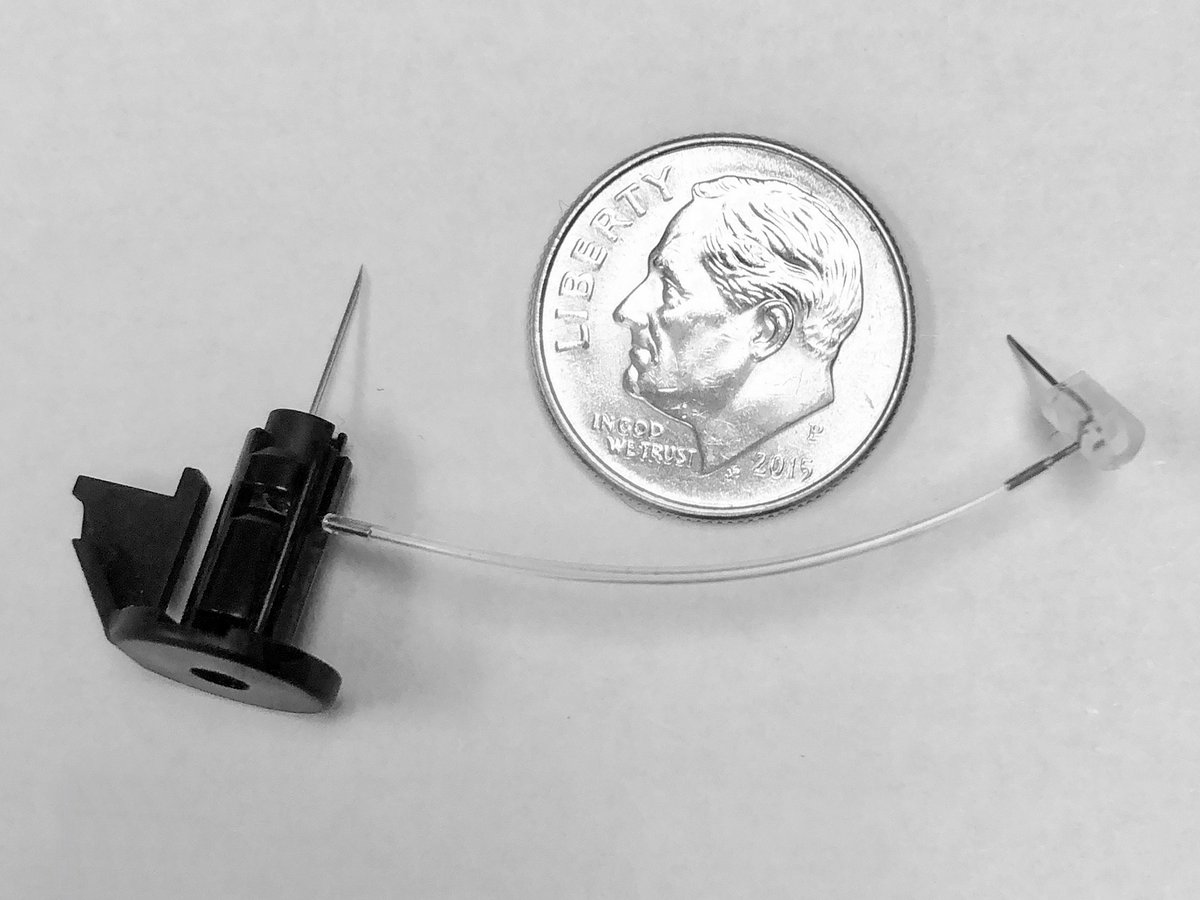

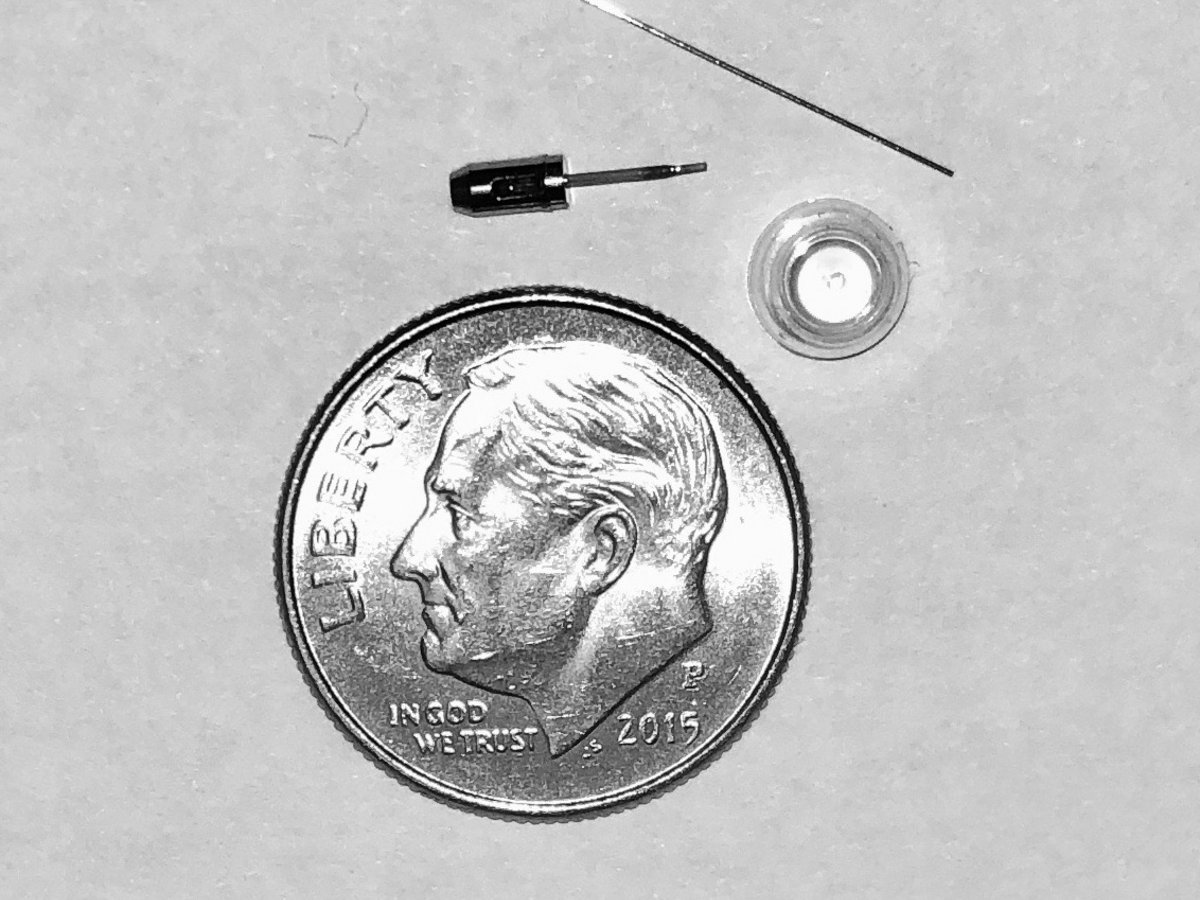

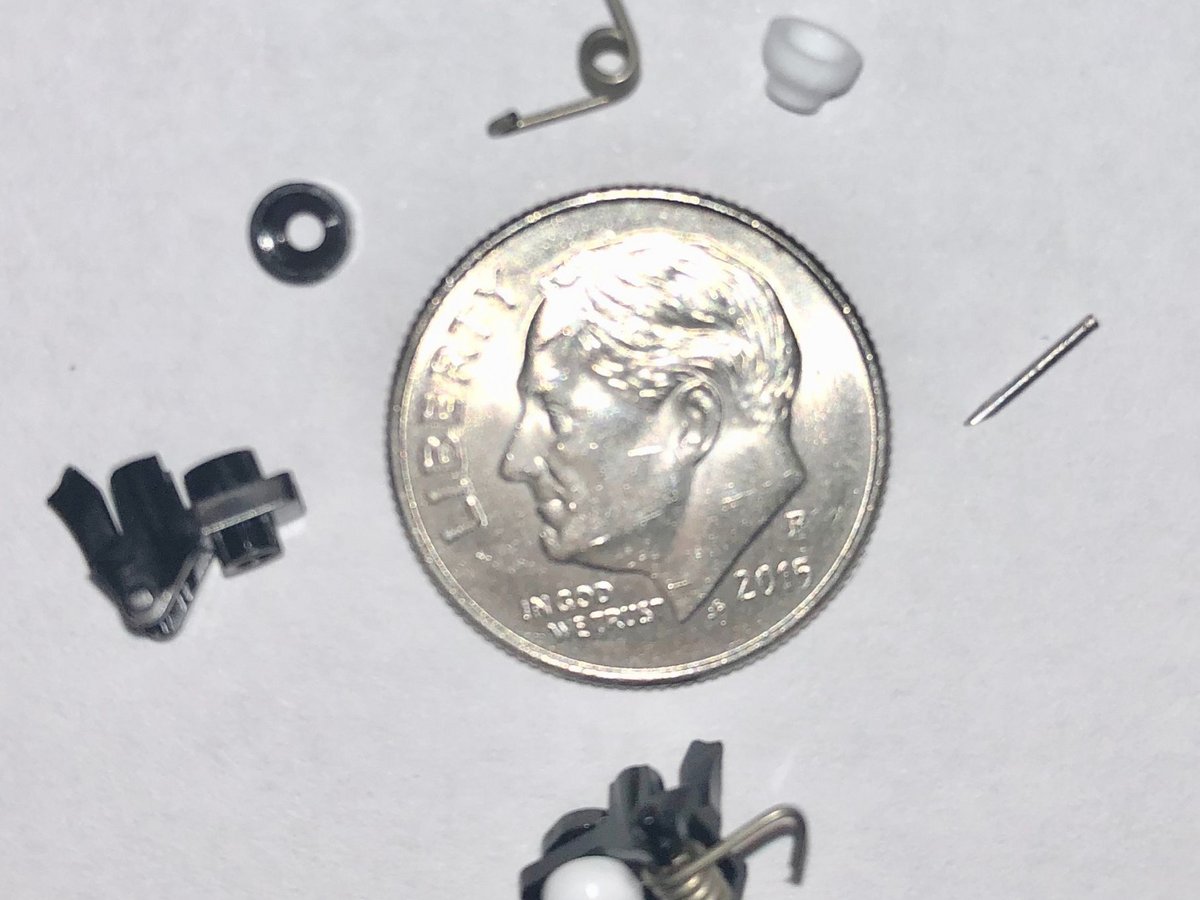

BBS has extensive experience in the complex feeding and assembly of critical Micro- Assemblies, components that are crucial to the functionality of the todays complex drug delivery and diagnostic devices.

BBS has designed and built micro assembly automation equipment with outputs from 10ppm to 630ppm. Our expertise includes the feeding and assembly of molded components, tubing and cannula as small at 6mm and 34G. Our equipment can integrate micro dispensing, vision, leak testing, punching filters and diagnostic mediums, welding, and cannula bending.

Get in touch with our experts

BBS Automation Caravaggio S.r.l.

Would you like to contact BBS Automation online?

Then use our online contact form!

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Influence of Machine Concepts on overall Equipment Effectiveness - EN

PDF / 2.03 MB

Influence of Machine Concepts on overall Equipment Effectiveness - EN

PDF / 2.03 MB