For teams responsible for internal assembly and testing projects

Whether you are involved in equipment manufacturing, industrial engineering or production management, the RTS platform is aimed at companies that regularly implement assembly and testing projects and are looking for a scalable, standardised basis for doing so.

- Equipment manufacturing / special machine construction

Easy integration of your own stations and processes - Industrial / manufacturing engineering

Rapid implementation of new variants and quantities - Production / plant management

Calculable investment, higher line availability, lower TCO

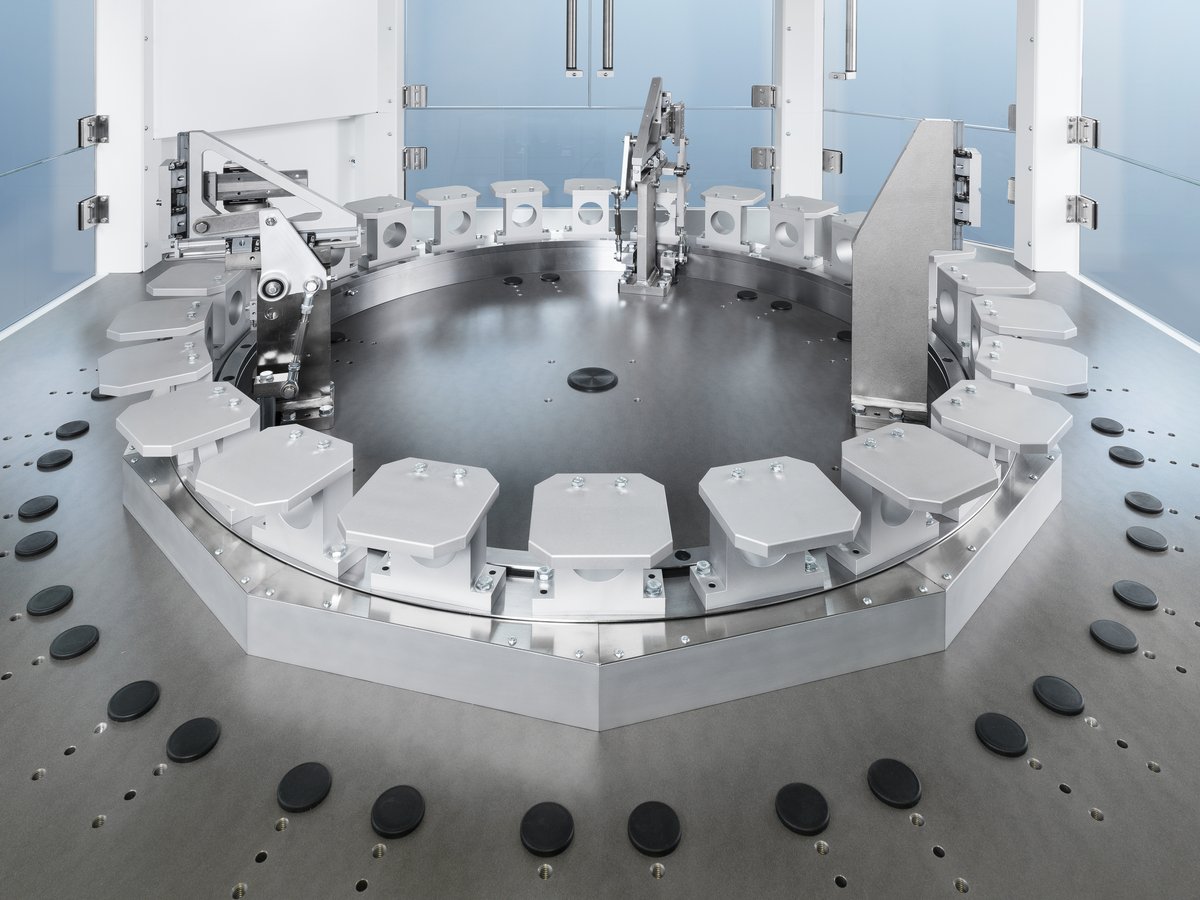

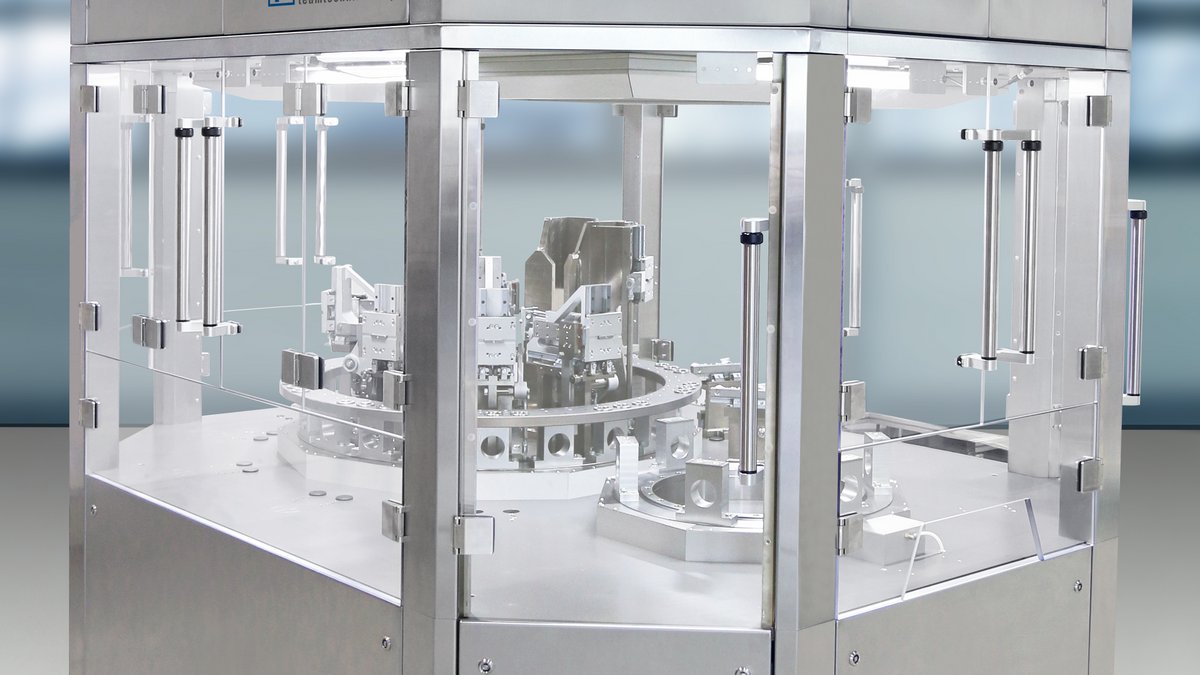

RTS – Your basis for modular assembly and testing systems

Flexible platform sizes

8 to 40 stations – suitable for simple processes to complex lines.

Linear plungers & drive combinations

Mechanical or servo motor drives – selectable depending on cycle time, variety of variants and range of parts.

Modular system for pick & place & processes

Numerous proven modules for feeding, joining, testing – less in-house development.

Long-term investment security

Platform can be expanded, converted and reused for new products.

Typical applications of the RTS platform

Geöffnet Typical applications of the RTS platform Konfigurationseinstellungen

- Life Science

Assembly of syringes, needles, IV components, disposables with high quality requirements. - Automotive / e-mobility

Assembly of sensors, connectors, valves, small drive or hybrid components. - Consumer & industrial products

Dental care products, fittings, electromechanical assemblies.

Find out more about TEAMED

Download now for free

BBS Automation - teamtechnik TEAMED RTS - EN

PDF / 919.72 kB

BBS Automation - teamtechnik TEAMED RTS - EN

PDF / 919.72 kB

FAQ: DIY vs. RTS platform

Because many assembly and testing projects can be completed faster, more reliably and with greater predictability when the foundation is already in place.

With the RTS platform, you don't start from scratch – the mechanics, drives and process modules are tried and tested and ready for immediate use.

On the contrary:

The RTS platform has a modular design (8–40 stations) and can be easily expanded or converted throughout its entire life cycle.

Many customers even use the platform for multiple products or product variants.

In:

- Concept phase

- Mechanical design

- Validation

- Commissioning

Defined interfaces, proven mechanics and standard modules often reduce implementation time by weeks or even months.

A central servo drive means:

- Fewer components

- Less complexity

- Less wear and tear

- Less maintenance

- Lower operating costs (TCO)

In short: easier to operate and reliable in everyday use.

Yes.

The RTS platform is designed to integrate individual tools, sensors, measurement technology and special process modules.

Many of our customers combine their own stations with RTS standard modules.

Yes, especially if:

- There is a high degree of variant diversity

- Processes are to be designed in a modular fashion

- Subsequent adjustments are planned

The RTS is also ideal for high quantities with up to 120 cycles/minute.

The platform is designed so that new stations can be easily integrated or existing processes modified. The RTS is ideal for product updates or new generations.

Get in touch with our experts

Jürgen Dietz

Would you like to contact BBS Automation online?

Then use our online contact form!

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB