The BBS location in Hallbergmoos has grown up with loading and take-out technology in and out of the injection molding machine – which is why we can offer an almost infinite range. When it comes to fast or complex take-out needs, we count on our linear robots in particular. However, we also use six-axis robots if they are better suited to the customer's requirements.

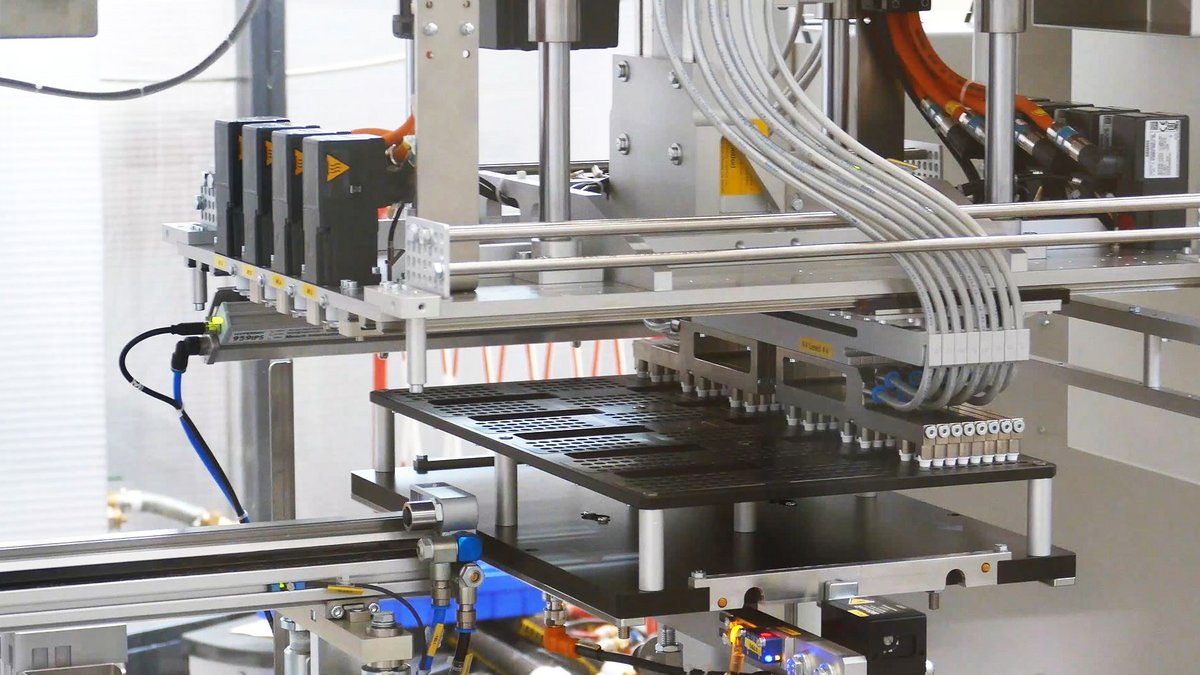

After take-out from the injection molding machine, the plastic parts can be further processed either inline or on our stand-alone assembly systems.

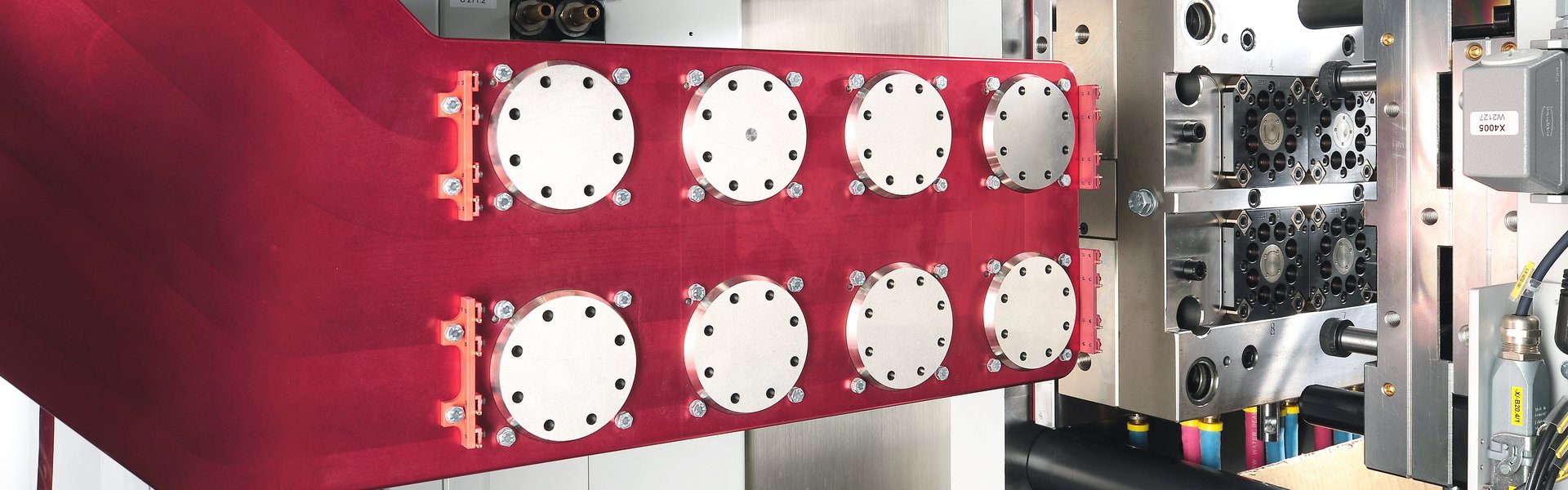

Variable number of cavities with high-speed take-out – Whether 2 or 128 cavities are required... with our robust robot design and precise gripper technology, a smooth take-out of the molded parts from the injection molding machine is achieved. This also includes the tiniest part in a small millimeter range. We are specialists in extremely high speeds, so that the take-out process can even perform better than free-falling parts. Of course, cycle time and mold open time are highly dependent on the product and the number of cavities, but in the optimum case we can boast a mold open time of 0.18 seconds with 16 cavities.

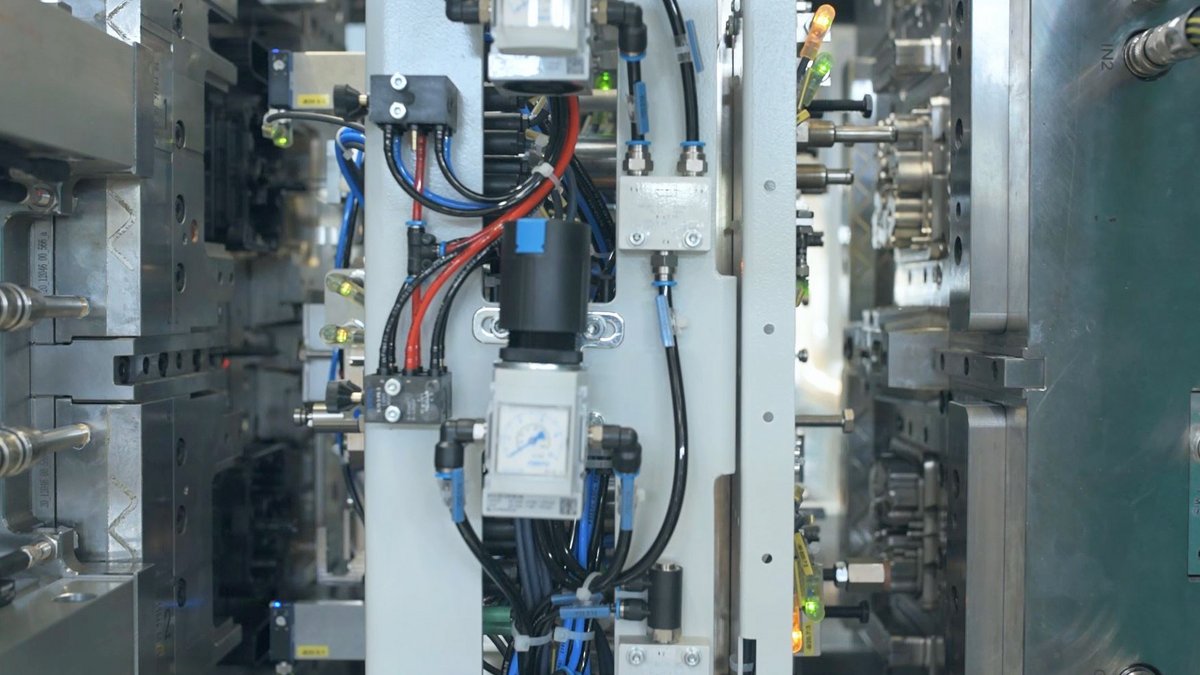

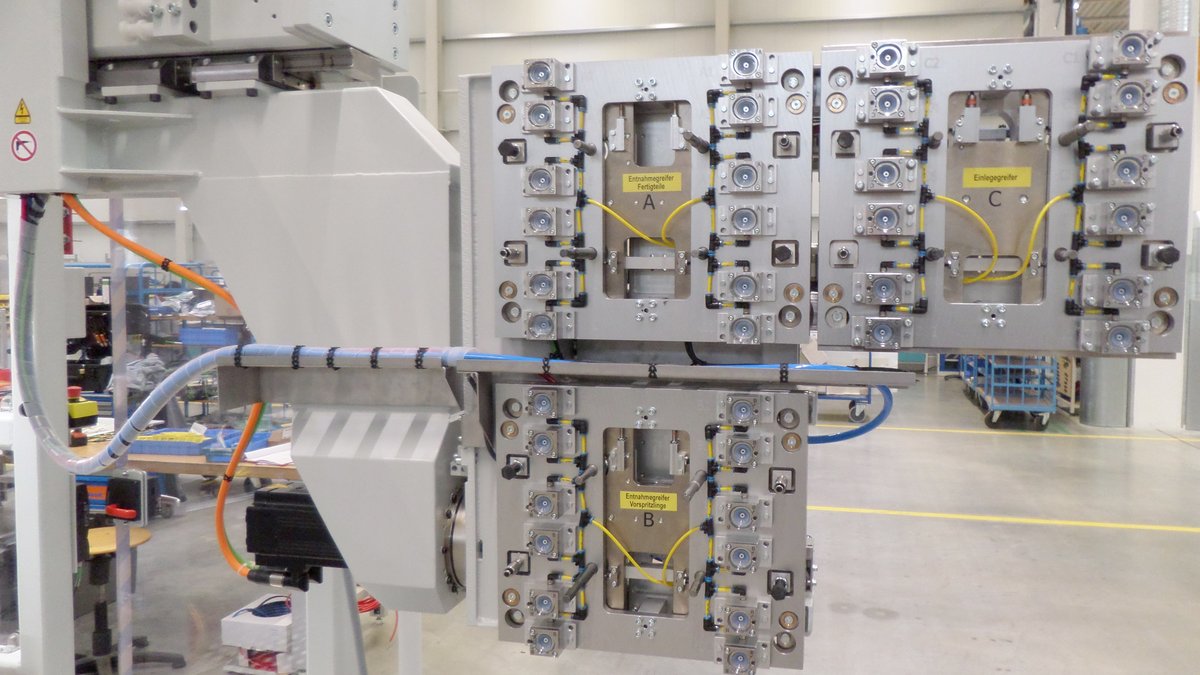

Simultaneous loading and take-out – In the case of metal/plastic composite parts, the potentially intricate metal components are prepared, separated, picked up by the gripper and loaded into the injection mold. At the same time, the finished parts, which have already been overmolded with plastic, are taken out from the mold. The complex process requires a great deal of know-how and first-class technology.

Multi-component injection molding – A 2 or 3 component injection molding process is used for personal care products in particular, for example to make parts of the product easier to grip. There are two production options. One variant is to manufacture the product on one injection molding machine and transfer the parts in the mold using BBS robots. The other option is to produce each part of the product on a separate injection molding machine. Here, the automation connects the injection molding machines and must therefore be coordinated with all components of the production process. For both versions, we are the right partner!

Cavity specific sorting – If desired, the parts taken out from the injection molding machine can also be handled cavity specific. This allows a clear allocation of the parts to a mold cavity in downstream processing operations. In the event of a part defect, a sorted handling makes it possible to easily trace and sort out the parts from the cavities concerned.

BBS Automation Hallbergmoos GmbH

Would you like to contact BBS Automation online?

Then use our online contact form!

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB