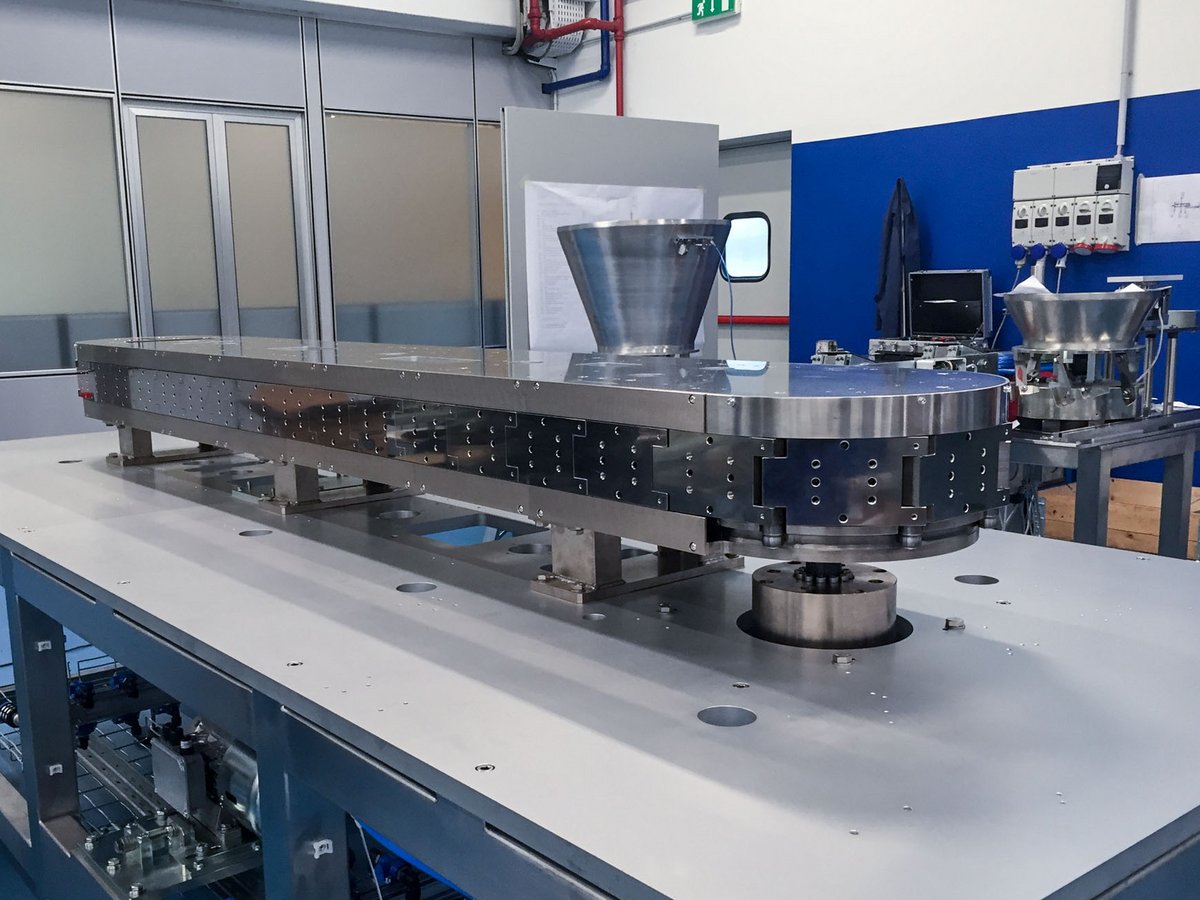

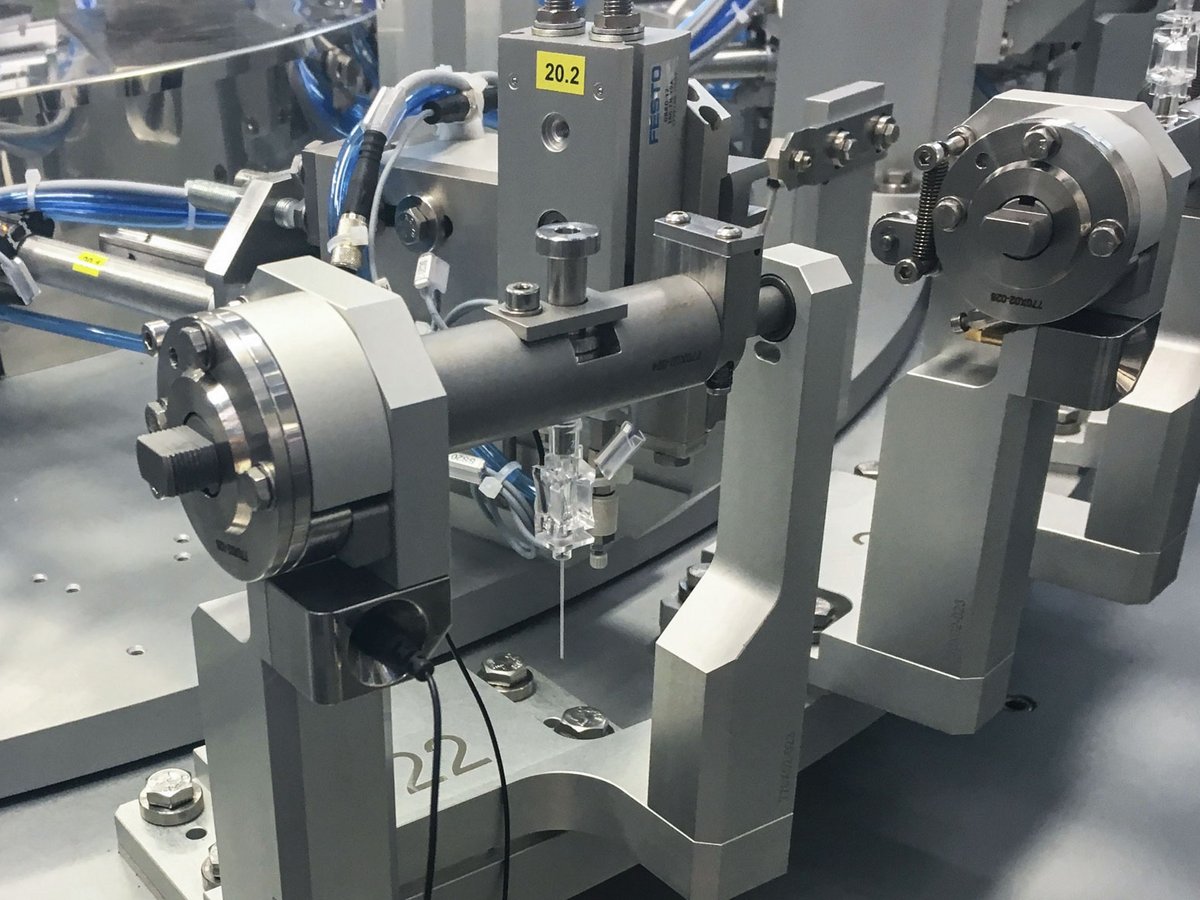

An Indexing Platform is chosen when an assembly or inspection task requires a fixed cycle time to perform. This platform also allows for flexibility when the product design and assembly process requires multiple components to be handled and assembled at a single station. The output rates can range from 30 parts per minute and exceed 1600 parts per minute depending on our customer’s requirements. Our experience in executing Rotary and Linear Indexing Platforms allows BBS to efficiently utilize clean room space and accommodate production space conditions.

Using exclusive technology, BBS Indexing Platforms offer a ±0.05mm or ±0.07mm indexing accuracy to provide precise index repeatability for consistent assembly and inspection of all components regardless of system size.

Get in touch with our experts

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB