In recent years, a lot has happened around the syringe development and production. Plastic syringes are becoming increasingly popular because they offer many advantages over glass, including break resistance. Prefilled plastic syringes are now also on the rise, as they can score in terms of sterility and optimized drug consumption.

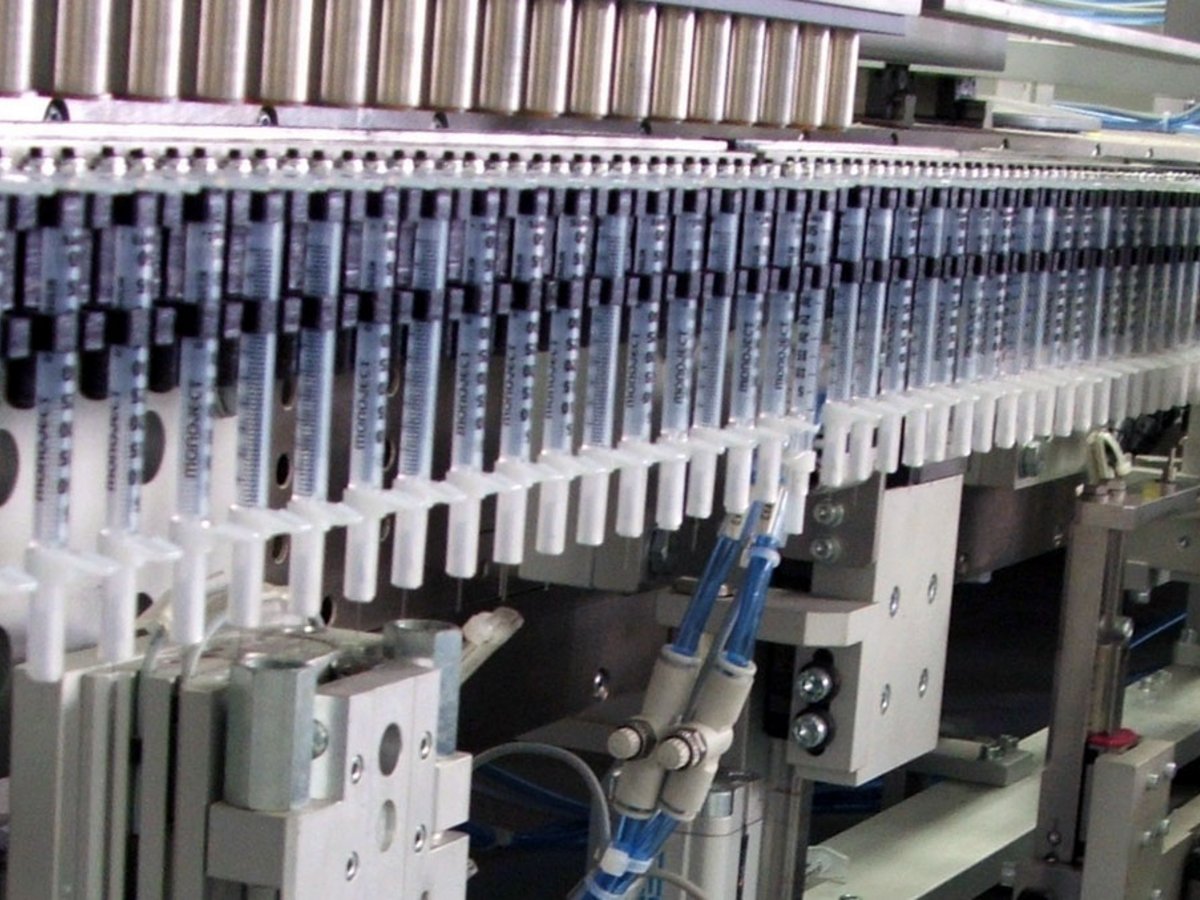

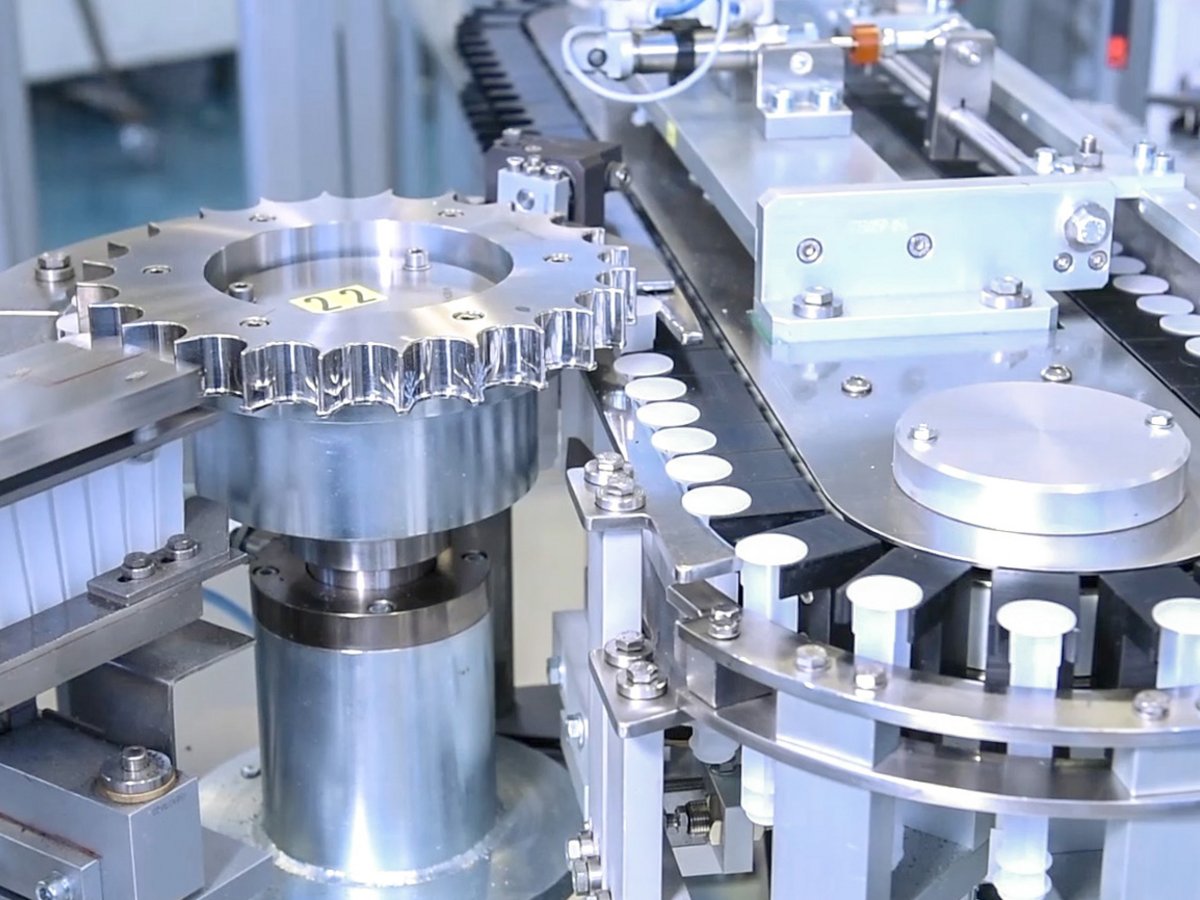

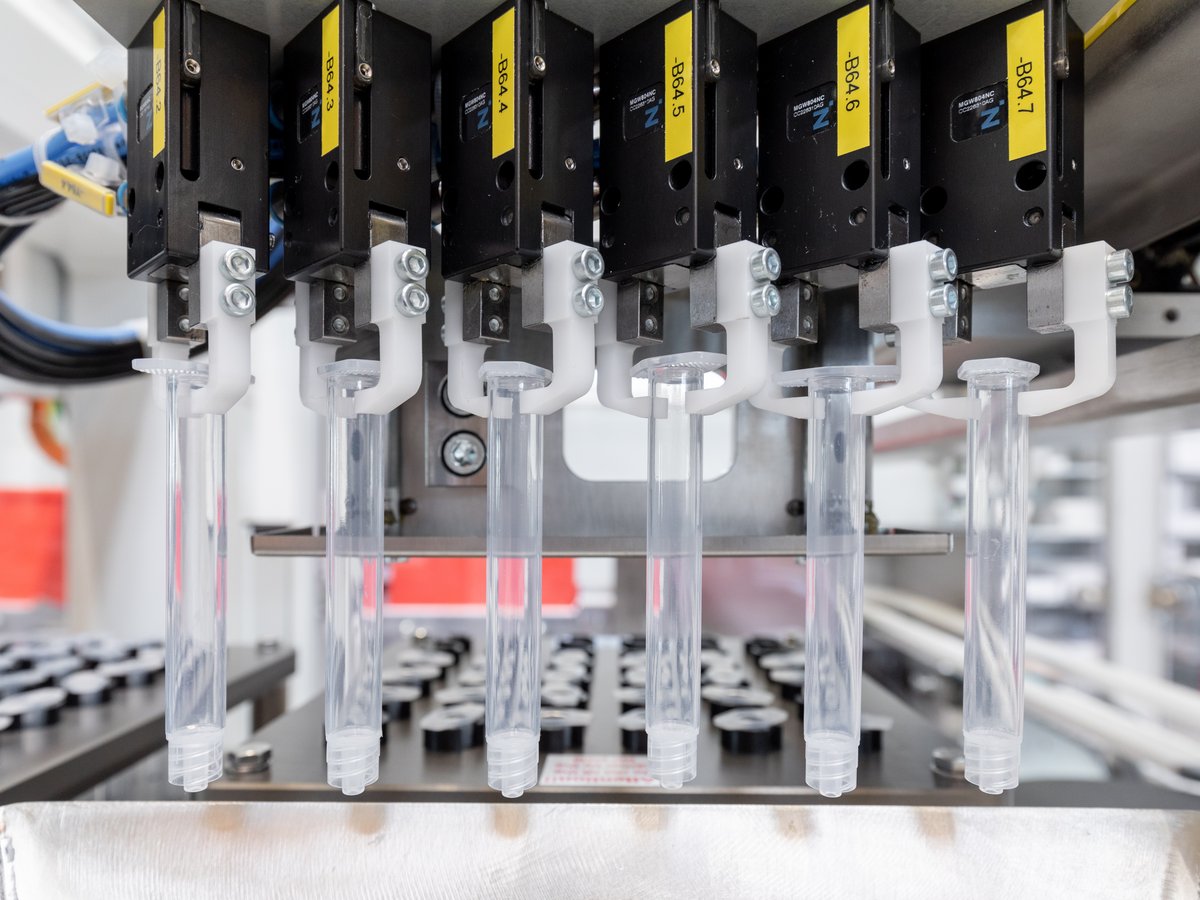

BBS Automation offers a complete line of Continuous Motion, Rotary Indexing, and Linear Indexing Assembly Systems to accommodate any type of syringe design. Whether it’s a standard design or a syringe with automatic or passive safety features, an autodestruct, or a specialty syringe design. BBS Syringe Assembly Machines can be designed to assemble and inspect the final product at output rates exceeding 1,000 parts per minute.

Of course, we are also the right partner for you when it comes to taking-out the single plastic components of the syringe or the accessories from the injection mold. Further downstream processing can be carried out either inline or on stand-alone assembly lines.

Your advantages at a glance:

- Fulfillment of quality and cleanliness requirements with minimal human intervention

- Concepts for a wide range of requirements such as such as the take-out of syringe parts and accessories from the injection molding machine, syringe assembly, reagent filling, etc.

- Possibility of full data tracking and traceability of syringes

- Systems for clean room production up to ISO class 6

Get in touch with our experts

BBS Automation Caravaggio S.r.l.

Would you like to contact BBS Automation online?

Then use our online contact form!

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Influence of Machine Concepts on overall Equipment Effectiveness - EN

PDF / 2.03 MB

Influence of Machine Concepts on overall Equipment Effectiveness - EN

PDF / 2.03 MB