Needle Assembly

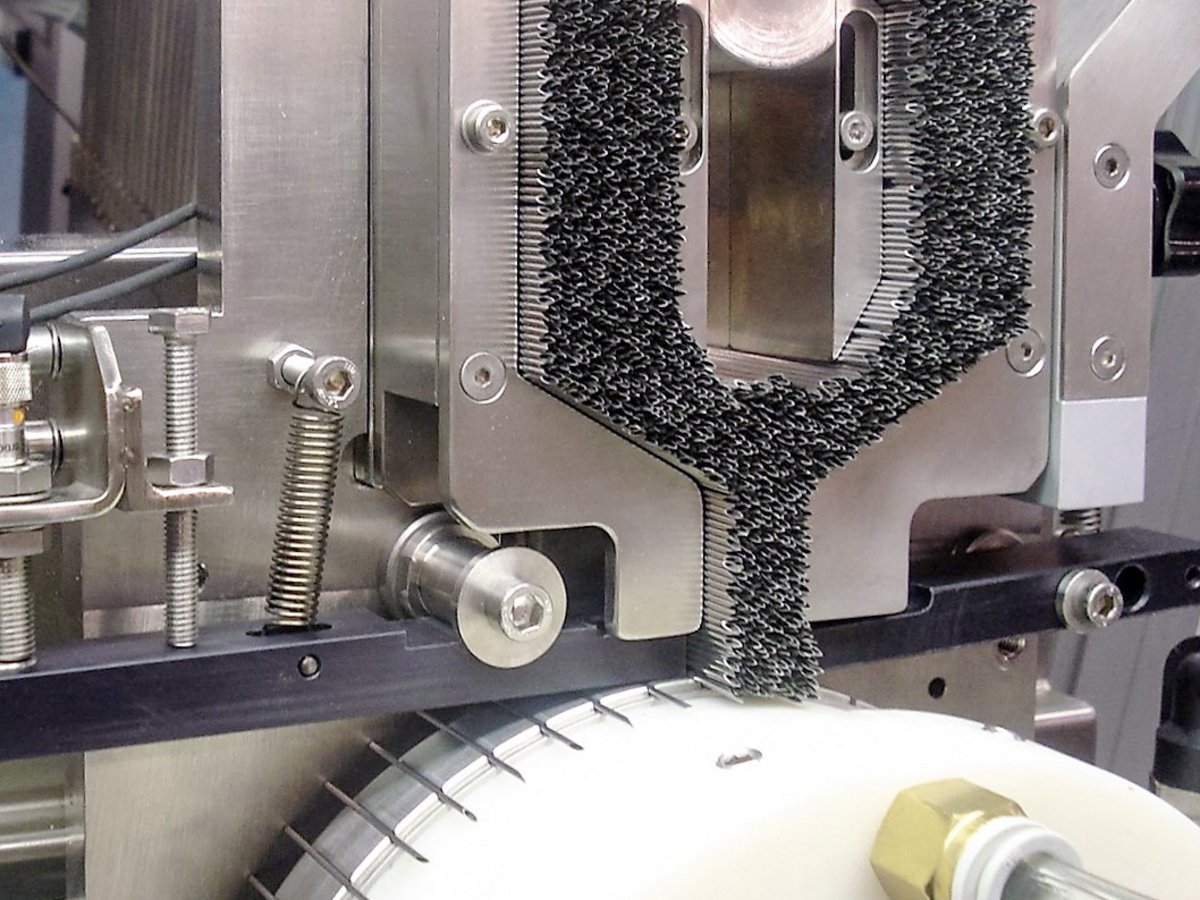

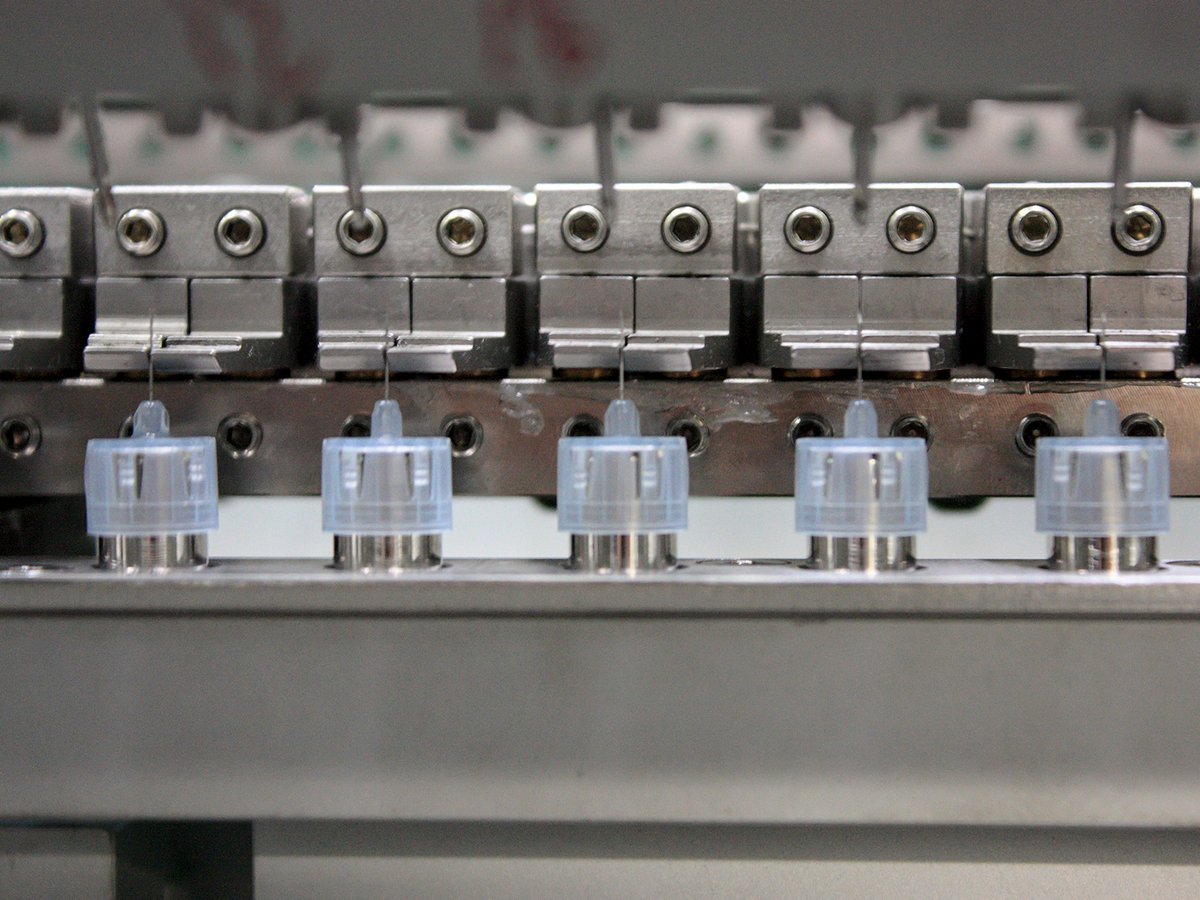

BBS Automation’s Needle Assembly Machines are available in various configurations, depending on product design and assembly requirements. BBS Automation’s precision systems are capable of assembling more than 50 needles at a time for outputs exceeding 1,600 parts per minute. Our proprietary BBS Needle Feeding and Bevel Orientation Technology can process needle sizes as small as 34 gauge without any risk of damage to the needle.

For more information on BBS Automation’s Needle Assembly Machines or any of our custom medical automation equipment, contact us today!

Needle Overmolding

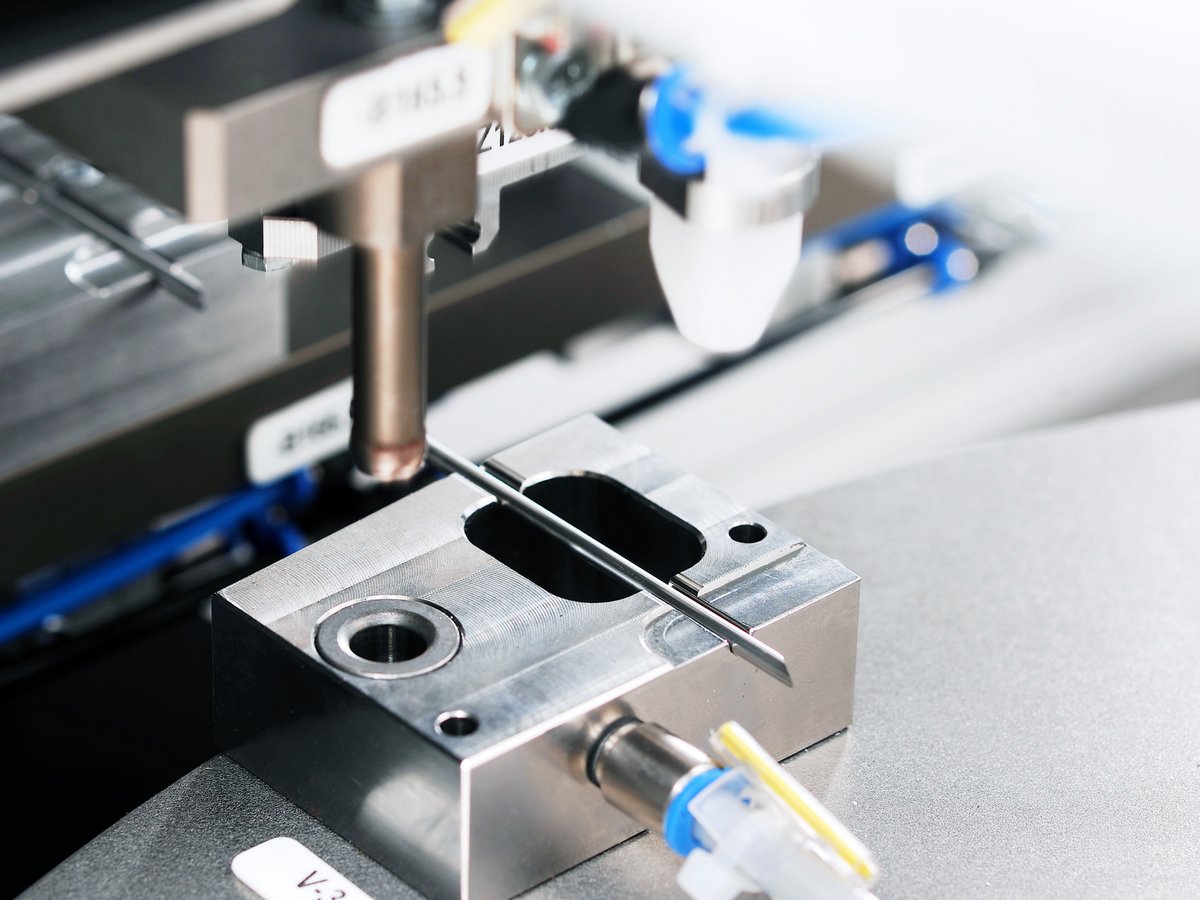

Another feature we offer is the overmolding of needles and cannulas. This means that the needles are separated, inserted into the injection mold, overmolded, taken out and further processed.

Your advantages at a glance:

- Fulfillment of quality and cleanliness requirements with minimal human intervention

- Separation and handling of needles and cannulas with a size range from 34 to 13 gauge and an orientation tolerance of +/- 1.5°

- Possibility of full data tracking and traceability of needles

- No risk of damage to the needle

- Systems for clean room production up to ISO class 6

Get in touch with our experts

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Influence of Machine Concepts on overall Equipment Effectiveness - EN

PDF / 2.03 MB

Influence of Machine Concepts on overall Equipment Effectiveness - EN

PDF / 2.03 MB