Life Science

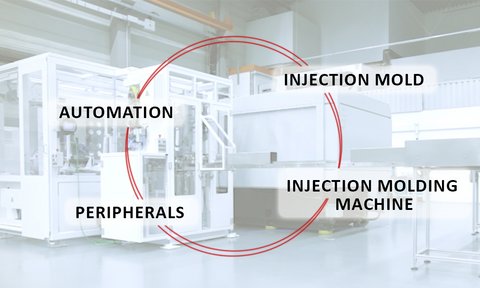

In the medical sector the brand specializes in automation systems for the production of disposable plastic products for labware, diagnostics and medication.

The focus is on platform machines with a high level of standardized automation steps, but customized solutions are also offered.

System Portfolio Life Science

With HEKUdish we offer a platform that fully meets all current market requirements for processing Petri Dishes.

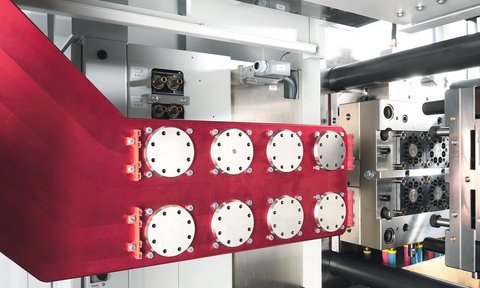

With a flexible design the system can be configured for specific products such as Contact Dishes and Cell Culture Dishes, providing you with a customized solution with maximized productivity and efficiency. The standard solution can be combined with various molds and injection molding machines from 2+2 to 16+16, from semi-automated to fully-automated.

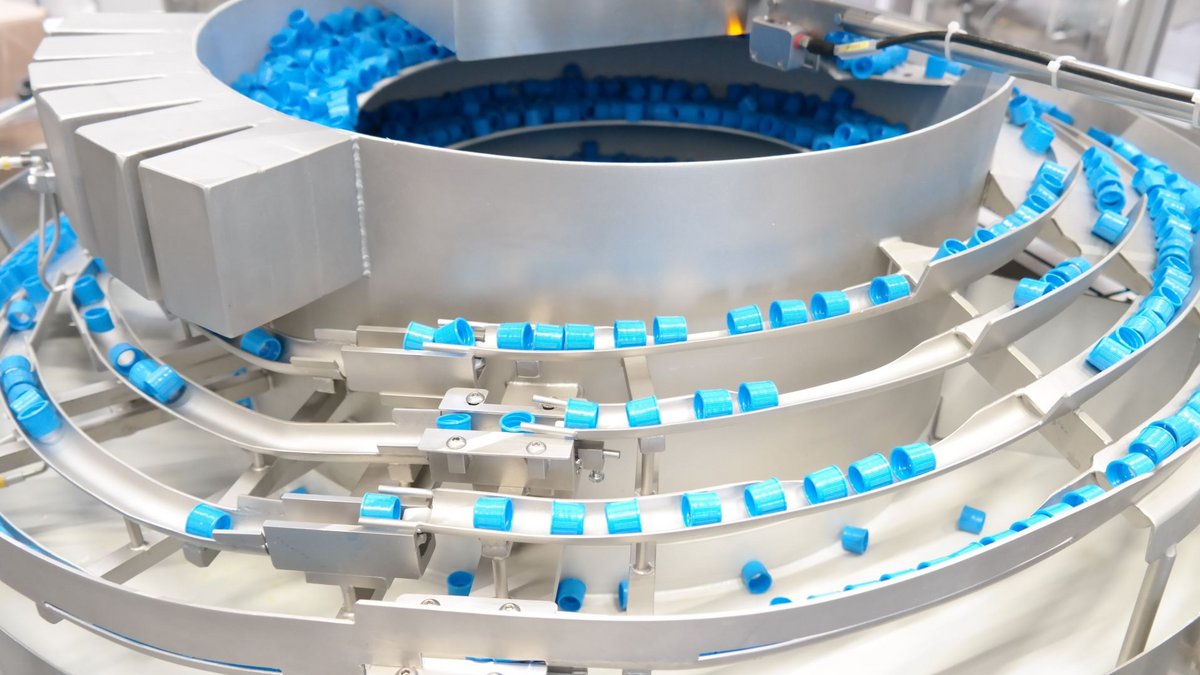

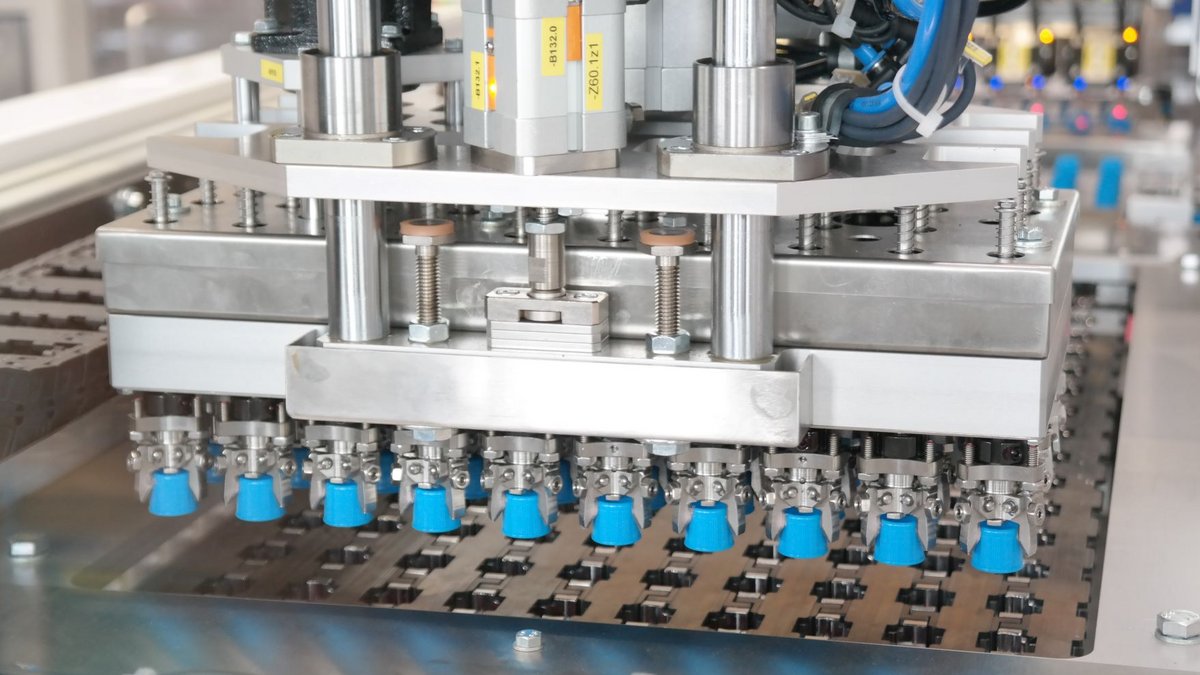

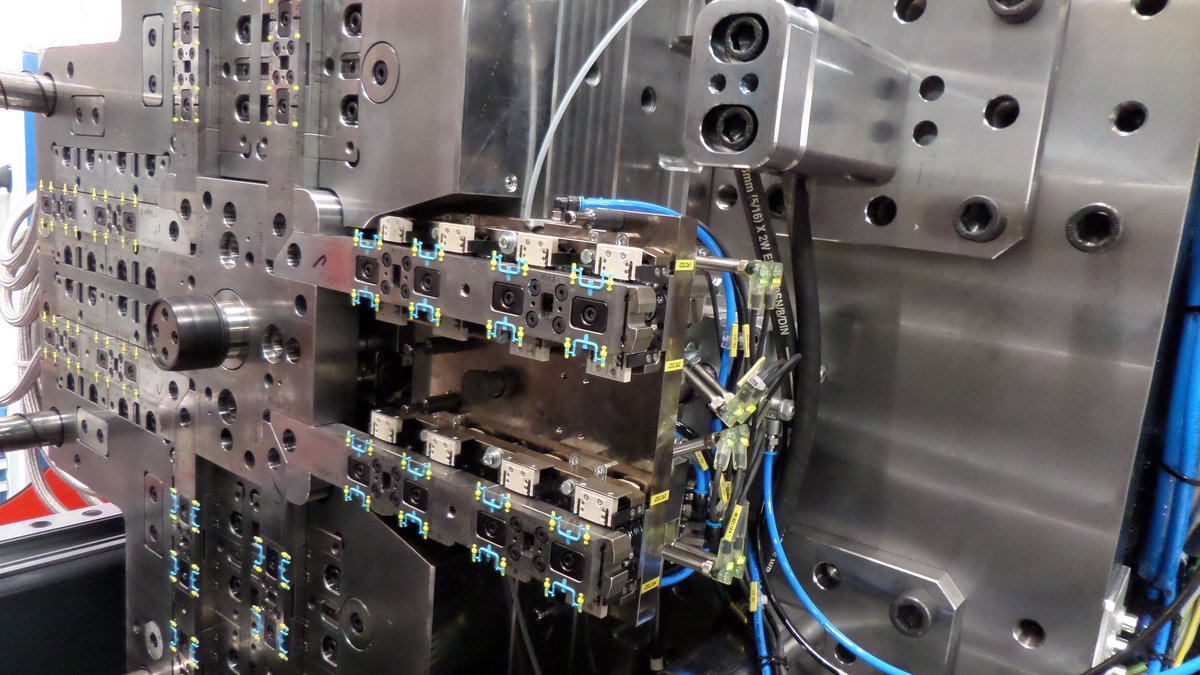

Our high-performance automation system, which can process up to 100 million vacuumed blood collection tubes per year, is the perfect solution for these quantities. The developed HEKUtube concept includes both a tube handling system connected to the injection molding machine as well as an assembly system with bulk material processed to the finished blood collection tube or a combination of both production lines. All current market requirements for the production and processing of blood collection tubes are taken into account.

Due to the modular and flexible design the system is able to process different reagants as well as tube sizes and quantities. As a result manufacturers receive a system completely customized to their needs.

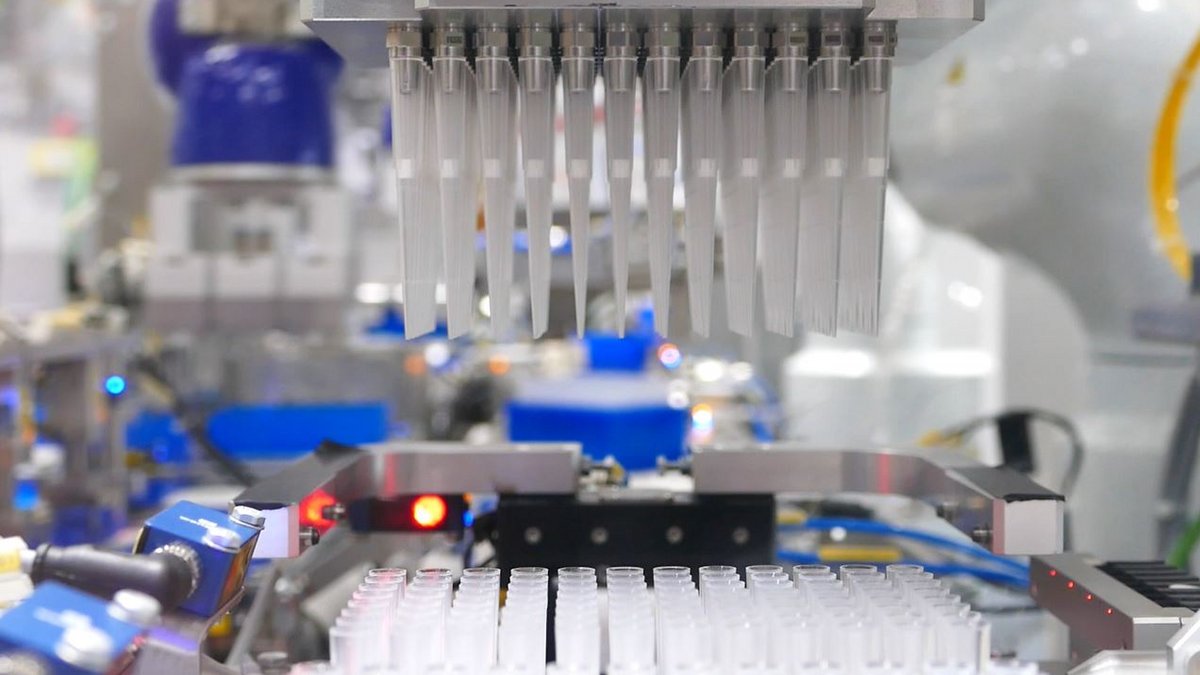

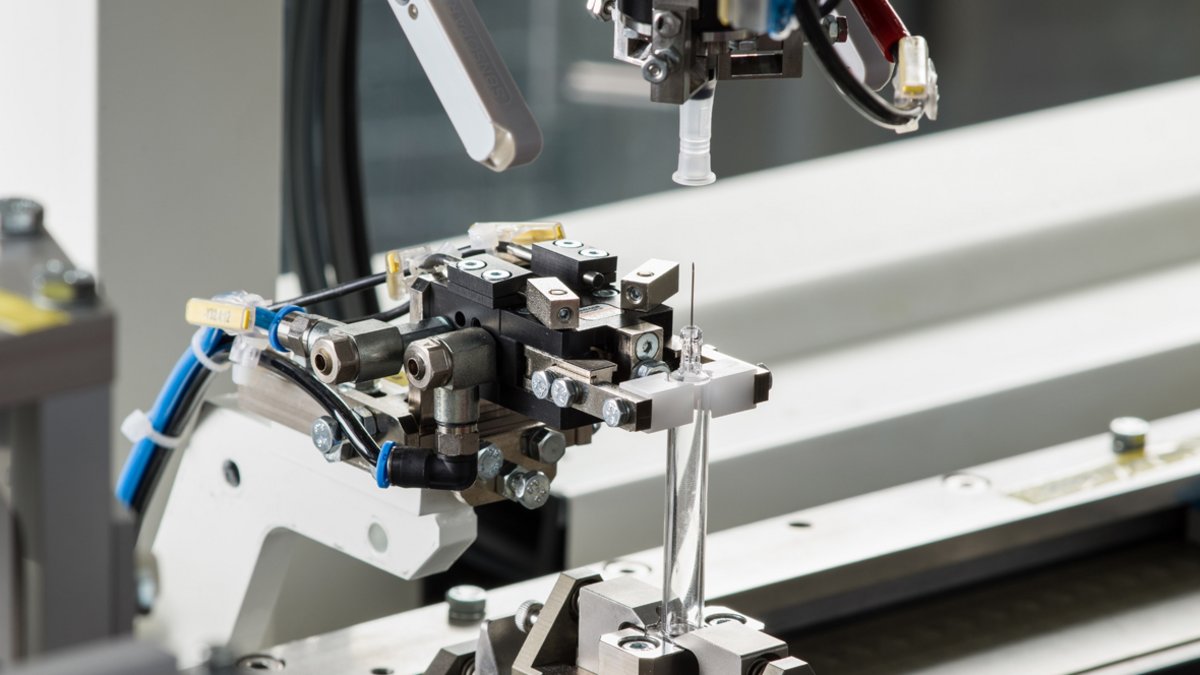

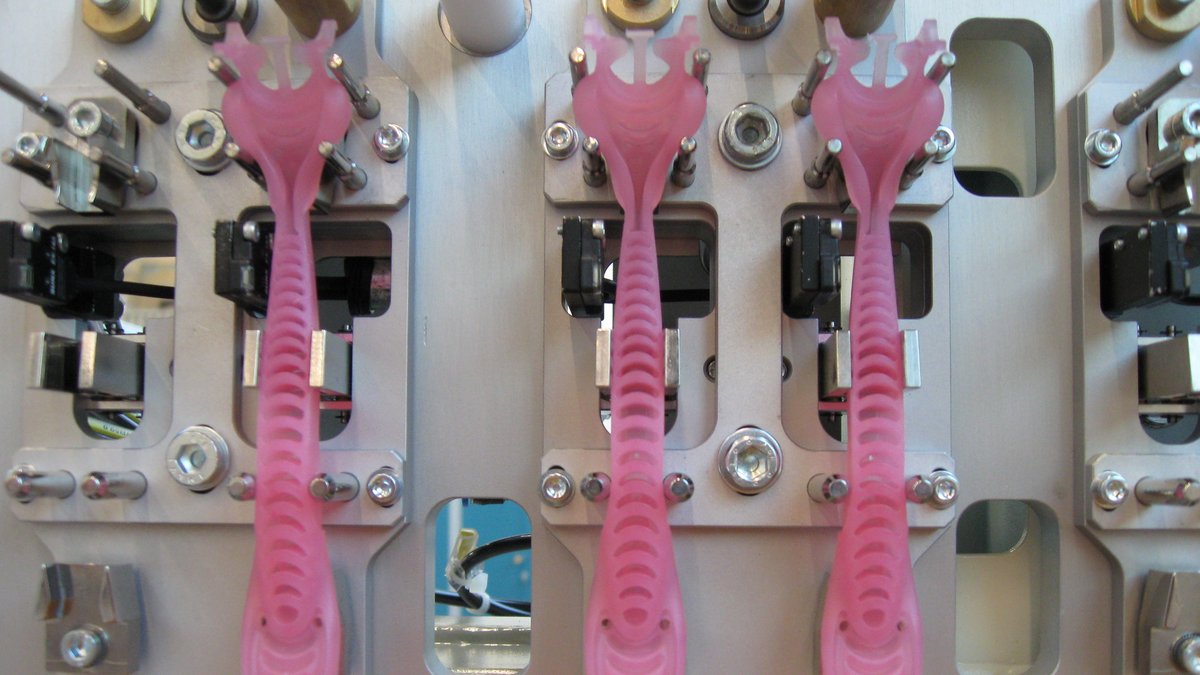

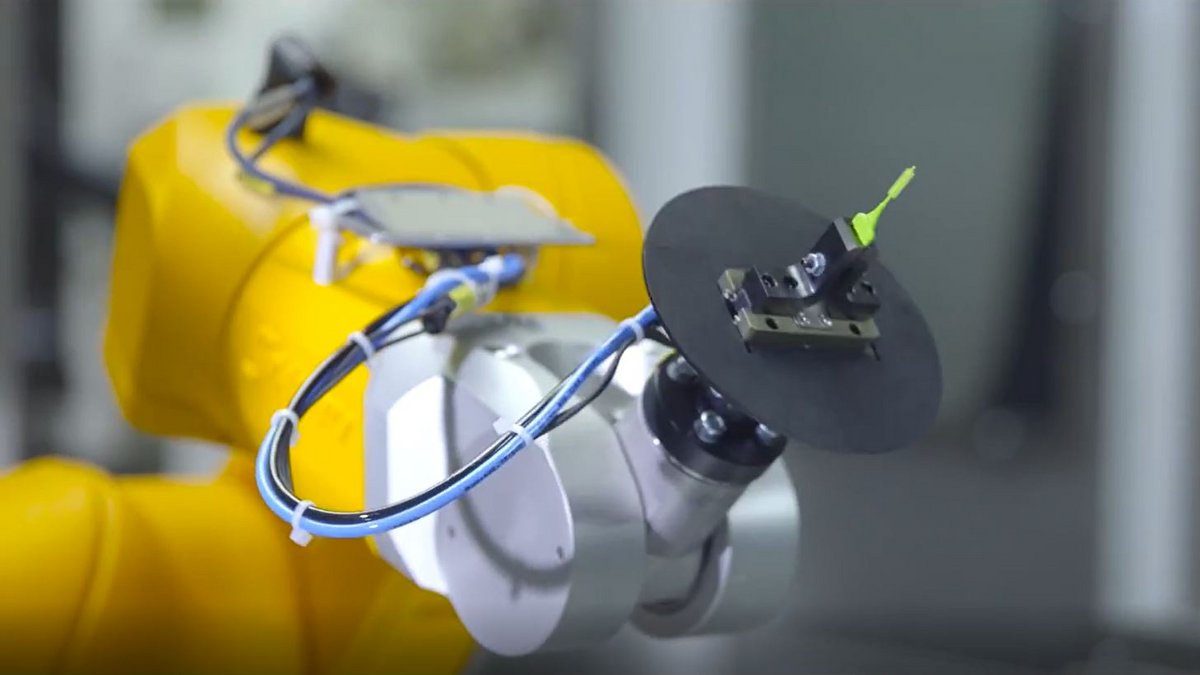

With our pipette automation systems HEKUtip we have created the optimal conditions for producig fast high-quality quantities. The take-out gripper with maximum speeds, the parallelization of process steps, the up to 100% camera inspection and the robust system design lead to extremely high output and availability.

Our HEKUtip concept provides various solutions for pipette tips: from the fully automated overall concept to the slimmed down TipLite version to the stand-alone filter assembly, from the take-out from the injection molding machine to the processing of pipette tip bulk material - depending on the requirements and budget of our customer.

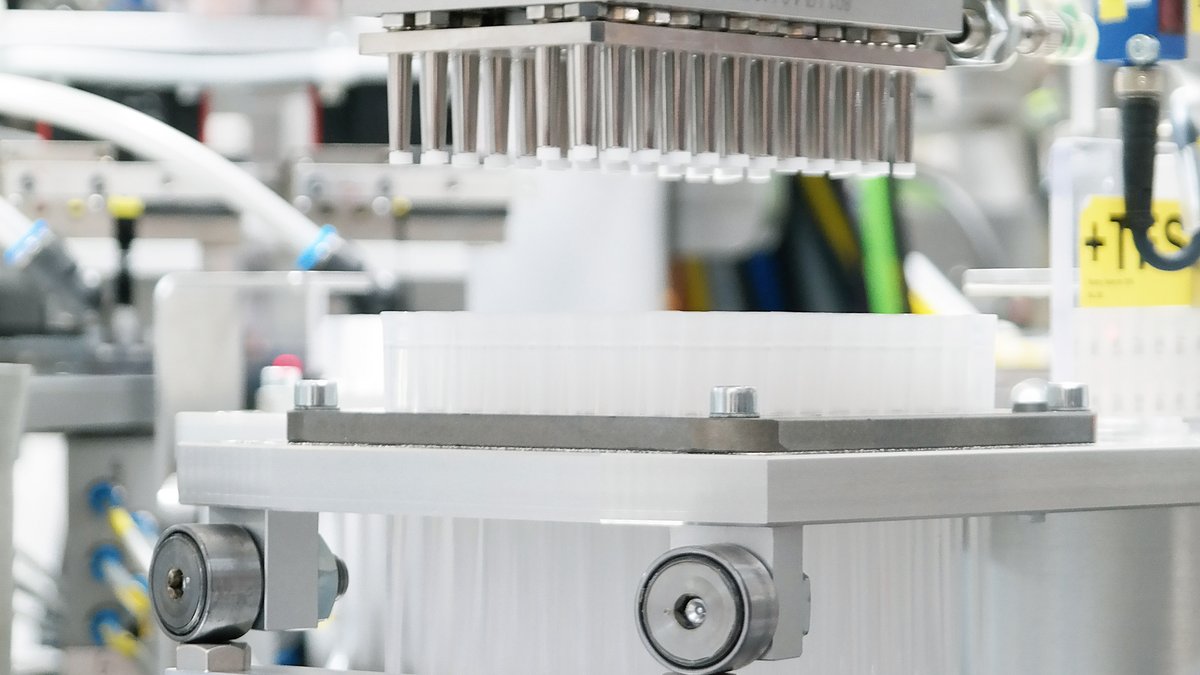

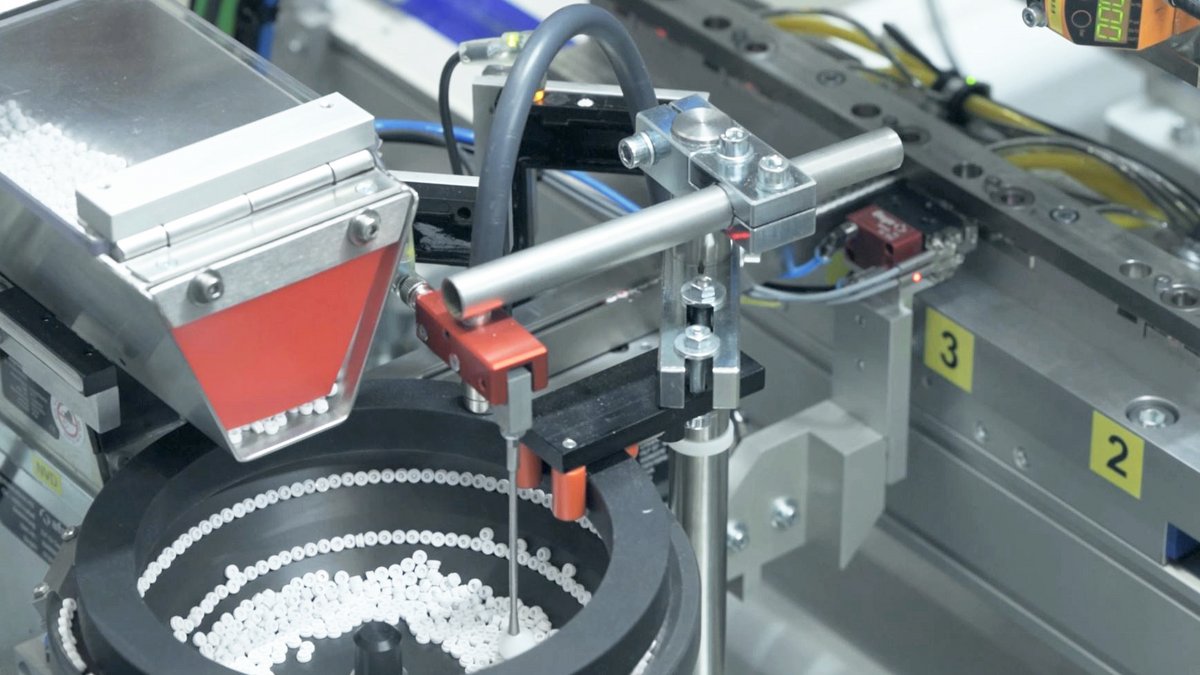

We have developed an automation solution to enable manufacturers to respond the increasing numbers of disposable laboratory parts such as reaction vessels, cuvettes, micro tubes, culture tubes, spin columns, etc. in a perfect way.

With the HEKUlab automation, a high quantitative output is guaranteed. A prerequisite for this is that the take-out gripper is able to handle und process simultaneously up to 128 cavities from the injection mold.

We offer a wide range of automation solutions in this area: From the production of needle holders and caps, to injection cannulas, to the assembly of (pre-filled) syringes, self injection devices as well as syringe filters.

Mobility

The HEKUMA brand specializes in systems for the production of small parts in large quantities for the interior as well as for drive and accessories.

With extensive technical know-how, we implement high-precision manufacturing processes with strict quality controls to ensure that all the safety-relevant and design-specific requirements of the product are met.

System Portfolio Mobility - HEKUmotive

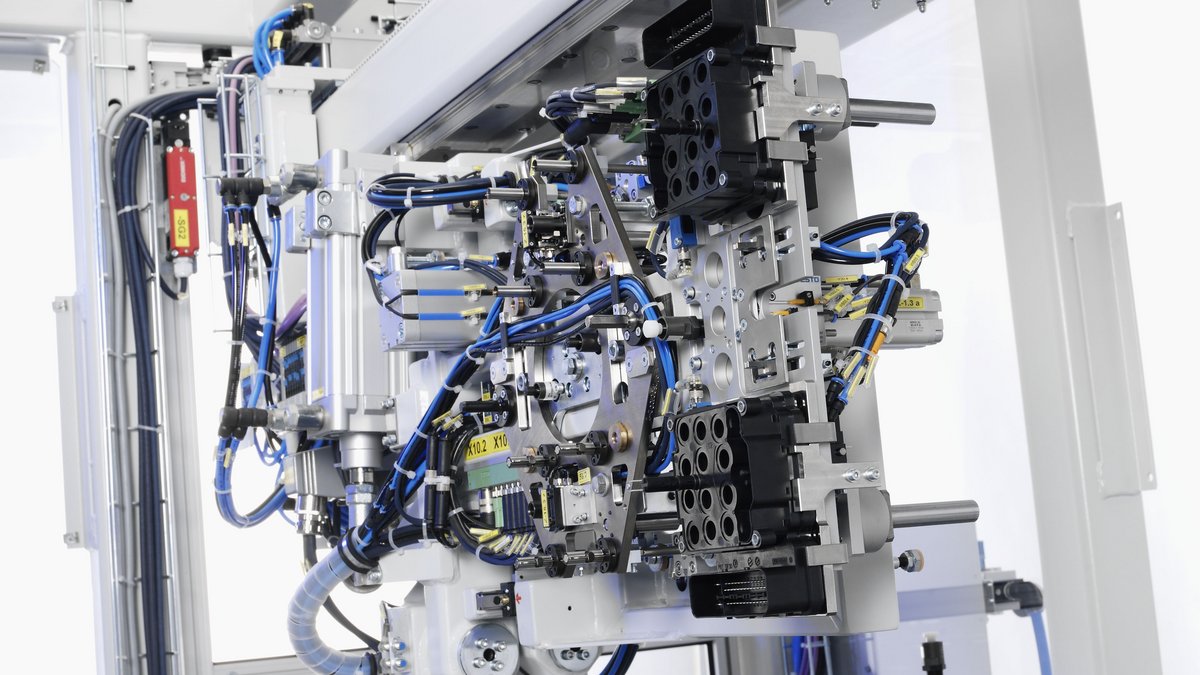

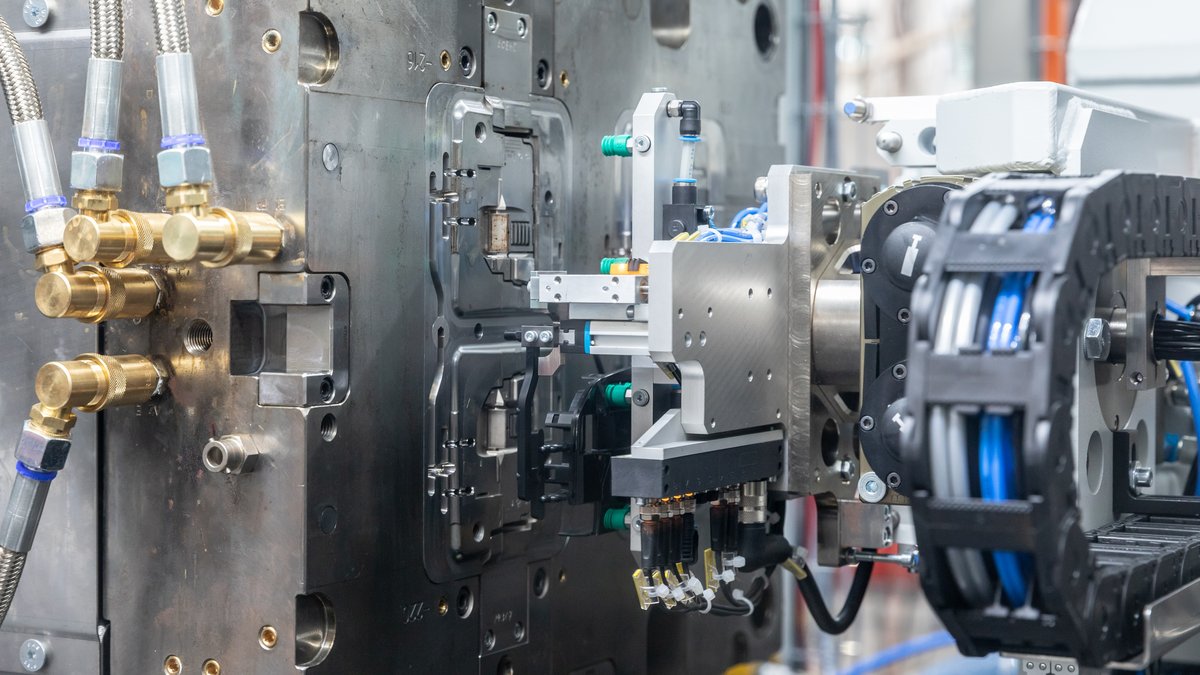

Whether housings for radar, ABS, ESC, sensors or connectors, whether components for transmission electronics and control,... HEKUMA HEKUmotive system covers all the necessary production steps: From preparing the contacts and pins, loading them into the injection mold, taking them out, a subsequent quality control through various inspection and testing processes, to marking and packaging.

The production of decorative plastic panels and displays for control systems in vehicle interiors requires maximum precision, quality and cleanliness in the production process.

Our HEKUmotive system meets these requirements completely and is therefore the perfect solution for overmolding 2D and 3D printed foils in a 1 or 2 component process.

Consumer Products

Across a wide range of consumer products, the HEKUMA brand has established itself as a developer of specific and sophisticated manufacturing processes for products within the field of care and cosmetic as well as for the energy and building technology sectors.

These include systems requiring cavity separated handling, extremely high cavity molds and short cycle times.

System Portfolio Consumer Products - HEKUconsum

The HEKUMA brand has already automated almost the entire spectrum regarding shavers and has many years of experience in the production of razor components and accessories.

Our fast and high-quality automation systems for take-out from the injection molding machine are the optimal solution for manufacturers of electric toothbrushes.

In addition to automation systems for various components of the electric toothbrush, we also have experience with other dental care products, such as interdental brushes.

Get in touch with our experts

BBS Automation Hallbergmoos GmbH

Would you like to contact BBS Automation online?

Then use our online contact form!

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!