Core Competence of BBS

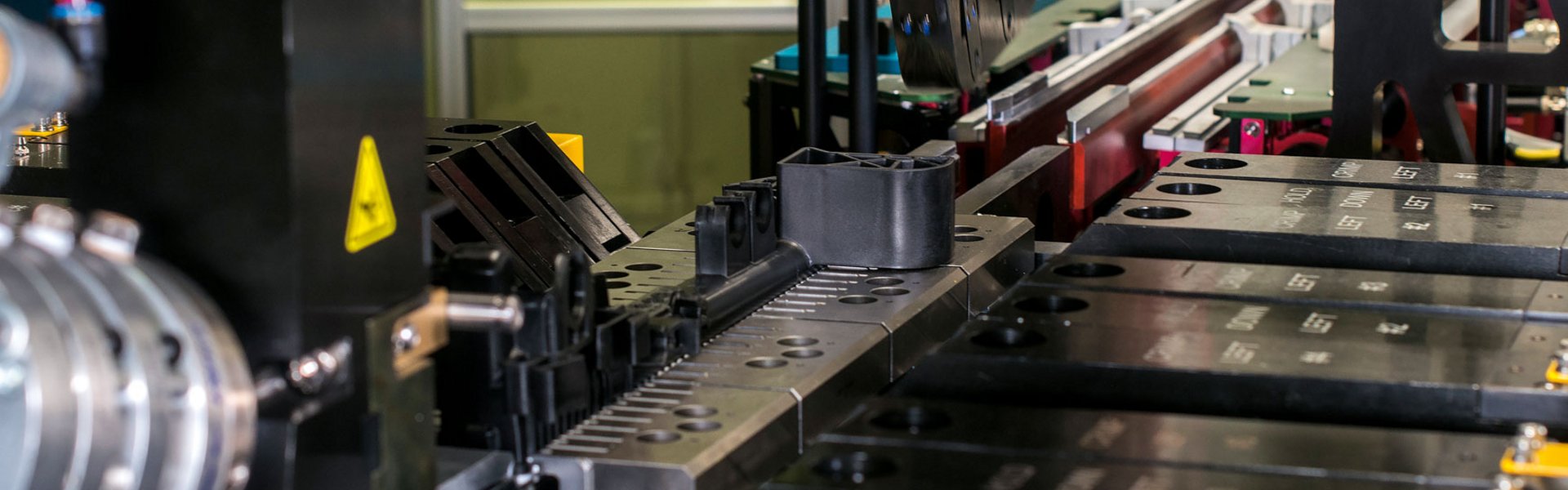

BBS Automation is your specialist for challenging tasks in the field of assembly automation. Our machines and systems assemble a wide variety of products for different industries. We deliver customized automation solutions that set standards in terms of economy, safety, reliability and profitability.

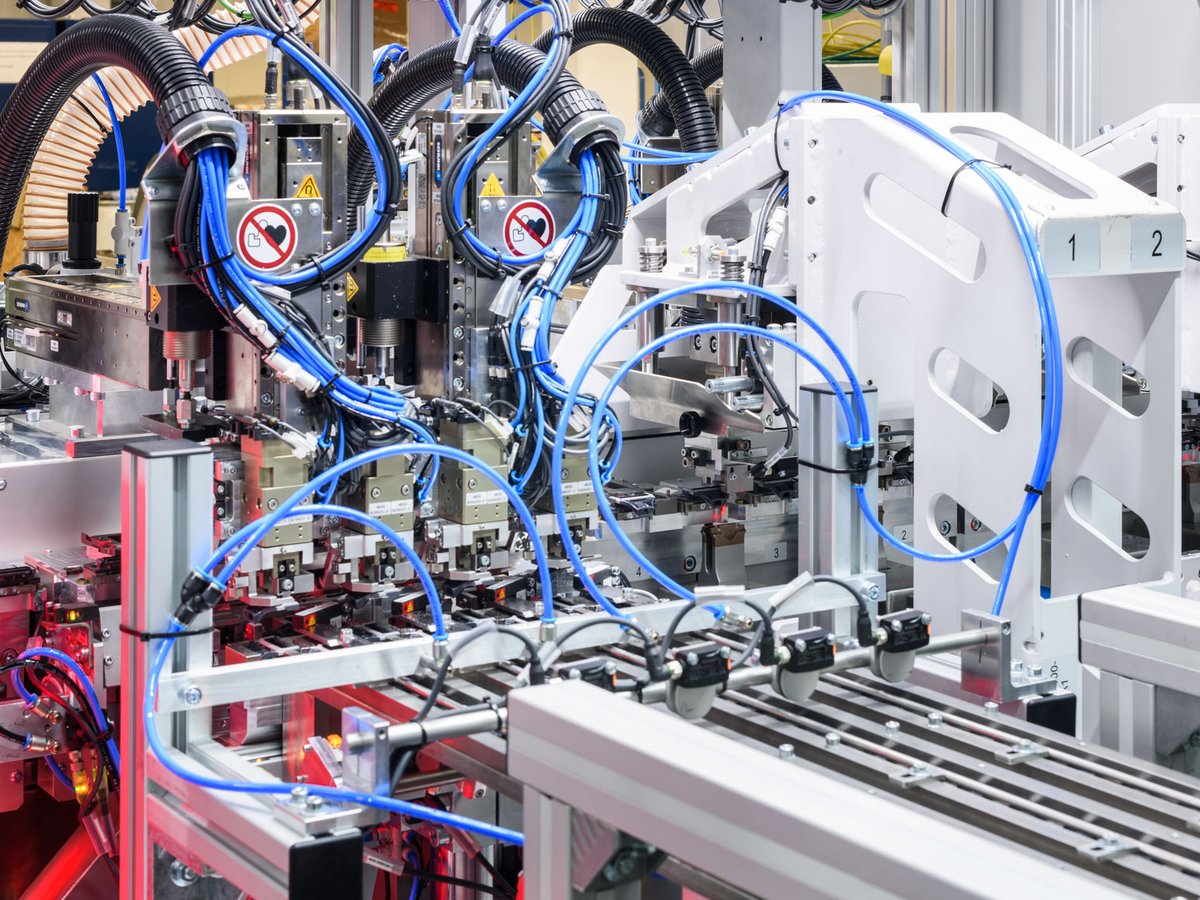

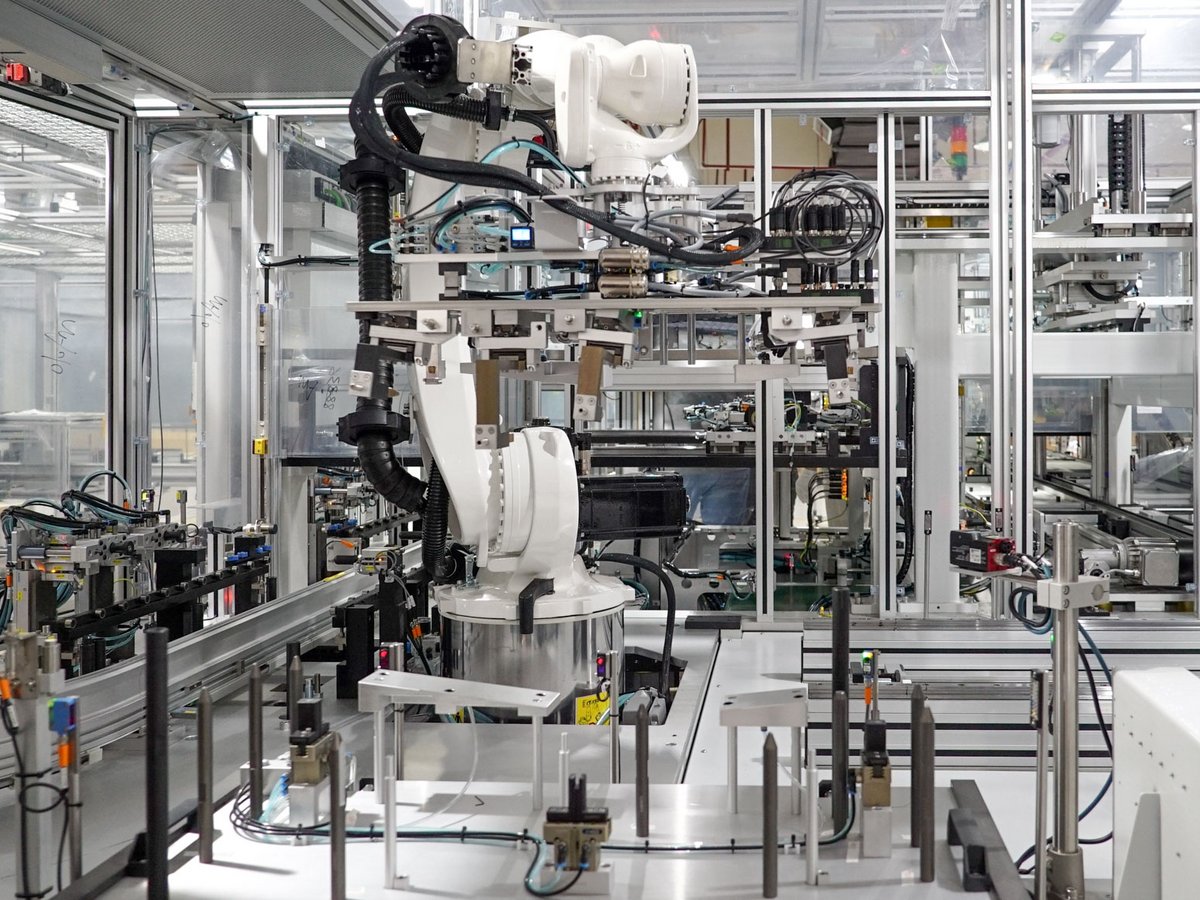

Machines and systems for assembly automation are planned, designed and built by BBS itself. After completion and delivery they are put into operation directly at the customer's site.The most different technologies, components, materials and methods are used for the realization. Depending on the specific requirements and the economically and technically accompanying environment, the machines and systems are either partially or fully automated. Our sales staff, development engineers, designers, electricians and programmers as well as tool makers and technicians work hand in hand to achieve optimal results, which often clearly exceed the customer's specifications.

BBS pays special attention to quality assurance and monitoring of the entire development process. In this way, we create modern and sustainable solutions for the automation market. Continuous development, progressive thinking, interdisciplinary cooperation as well as flexible and lean structures create a foundation for our innovative machines and systems - Ready for Industry 4.0.

Facts about Assembly Technology

- BBS systems offer maximum flexibility through the use of state-of-the-art technology and modular design

- Optimization of assembly processes processes and system commisioning through virtualization and digital twins

- Sustainability and economic efficiency through the automation and other technical disciplines

- BBS production lines are developed for continuous operation and guarantee high availability and optimum cycle times

- Absolute precision in the assembly processes ensures excellent results and products

- Customized solutions for highest product quality and customer satisfaction

Our Advantages

- Wide experience and various product range

- Global footprint of BBS

- Multilingualism of employees

- Tailored, customer-oriented solutions

- Optimized build times with 100% monitoring, reliability, quality

- Global project management and service support

- A key account team conducts each project

Integrated Processes

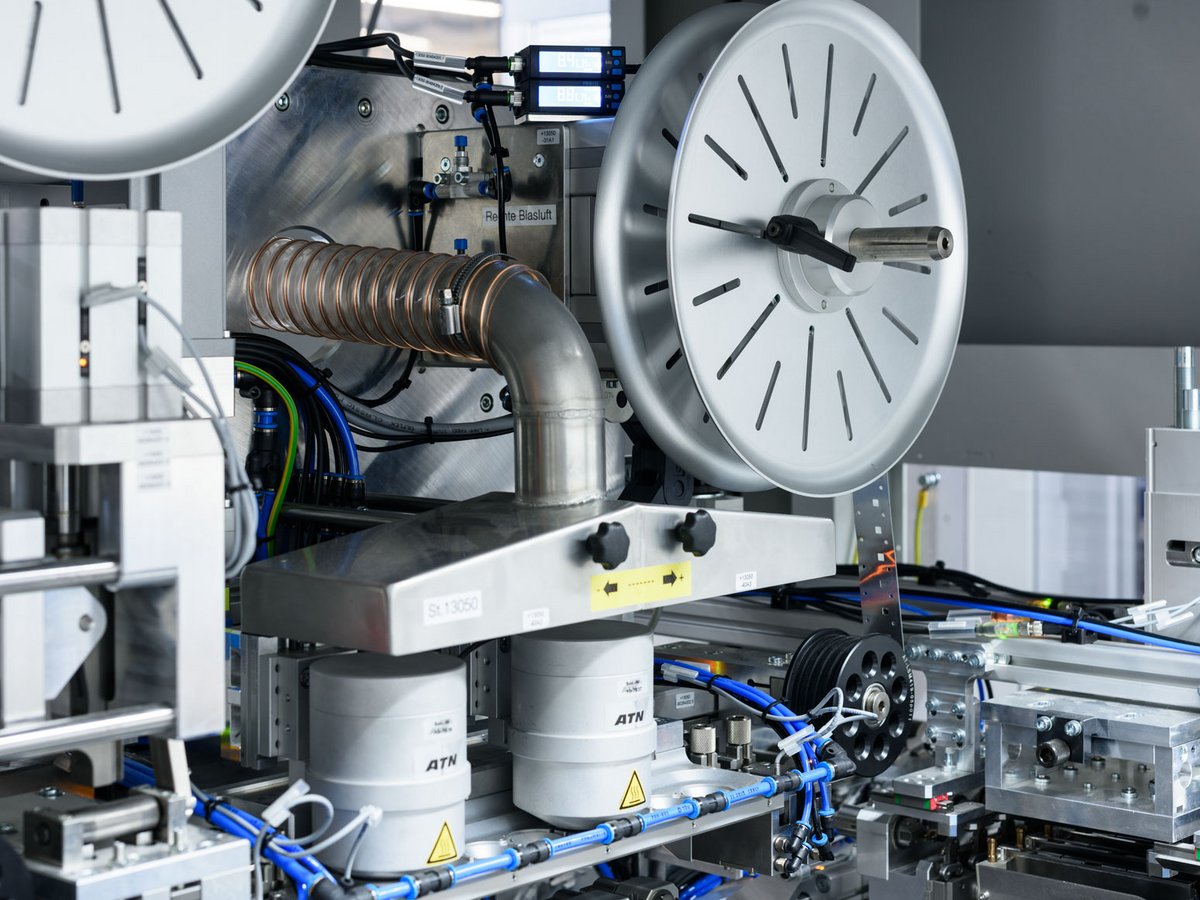

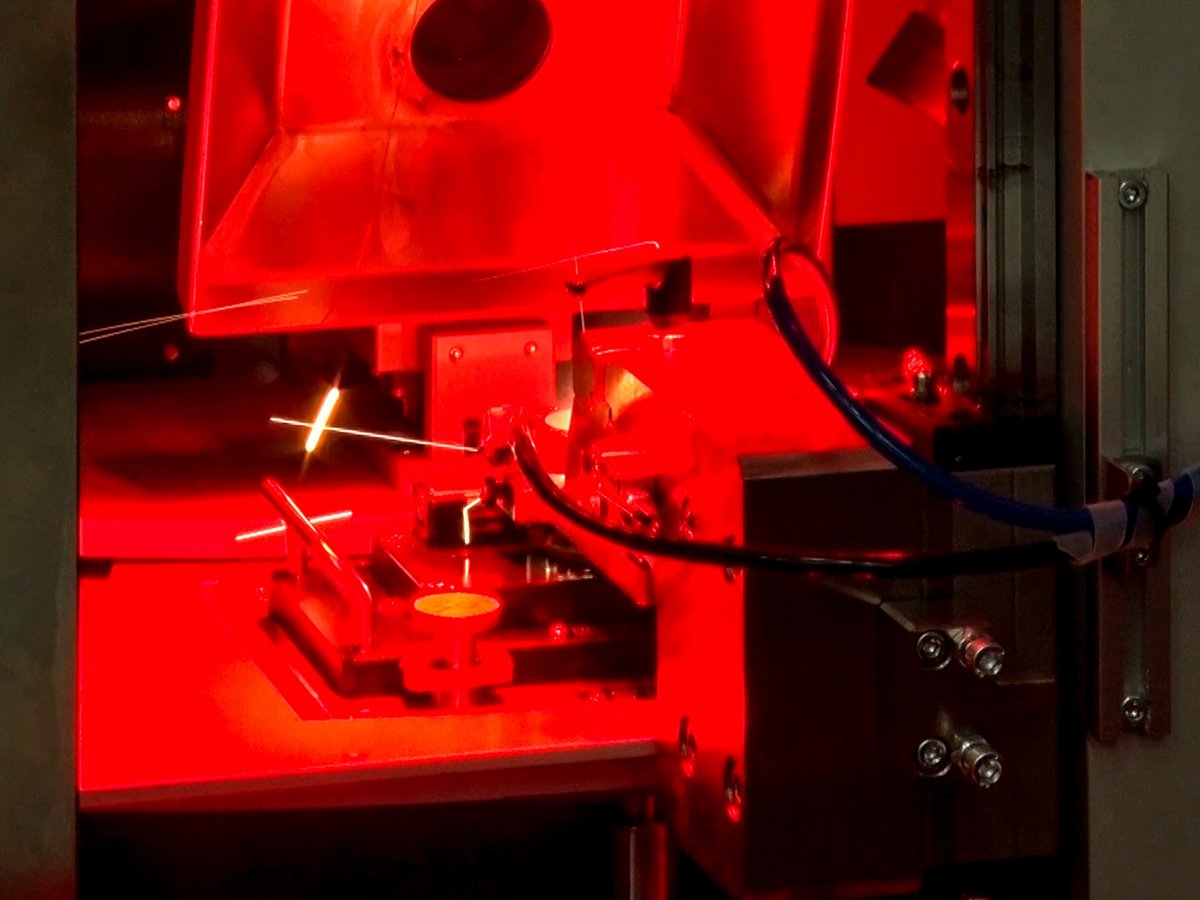

BBS machines are designed for the assembly of a wide variety of products. Depending on the requirements, different manufacturing processes are combined and integrated in our systems, such as:

- Connecting

- Dosing

- Feeding

- Gluing and dispensing

- Greasing and oiling

- Handling and transport

- Identifying and marking

- Laser cutting, drilling, hardening

- Positioning and inserting

- Screwing

- Separating

- Sorting

- Transforming

- Welding, soldering

- Weighing

- Testing

- Packing

- Labeling

Get in touch with our experts

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!