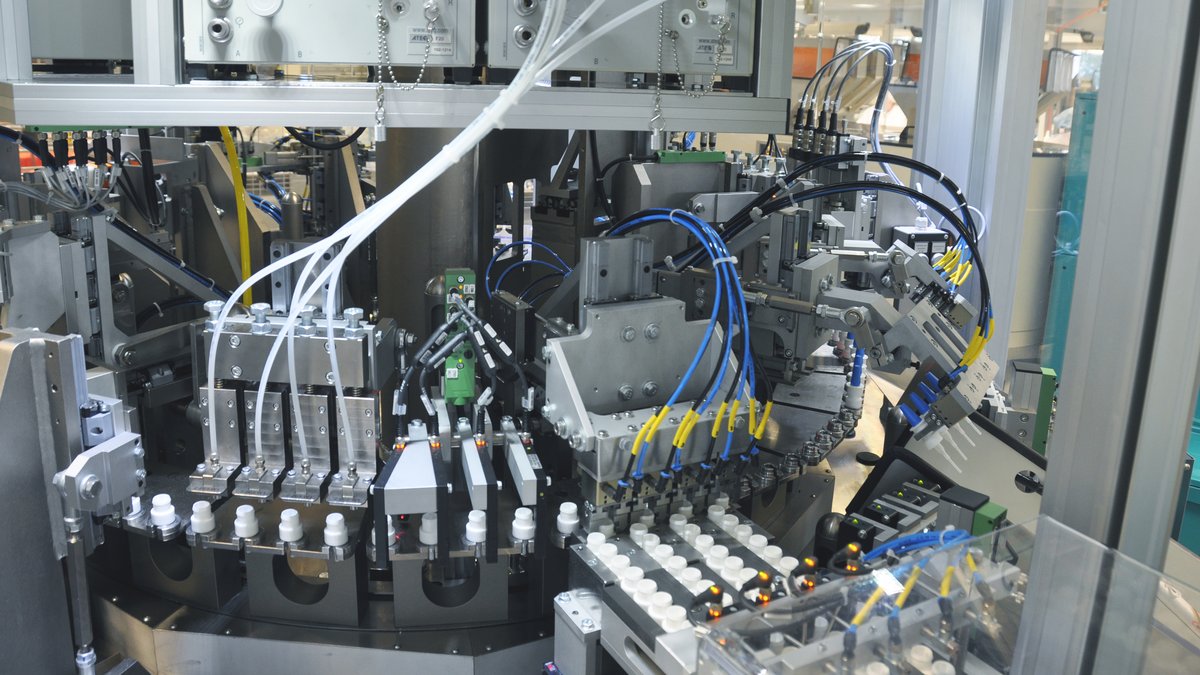

Dosing pumps, stopcocks, tube sets and other medical devices are mass-produced in large quantities. We developed the TEAMED RTS assembly system especially for this purpose. Its mechanical cam drive guarantees stable processes and high quantities for decades - with 24/7 production.

High-speed assembly calls for individual parts to be sorted, fed and presented error-free and with split-second accuracy. This is exactly where our focus lies - in our competence centre for feeding technology.

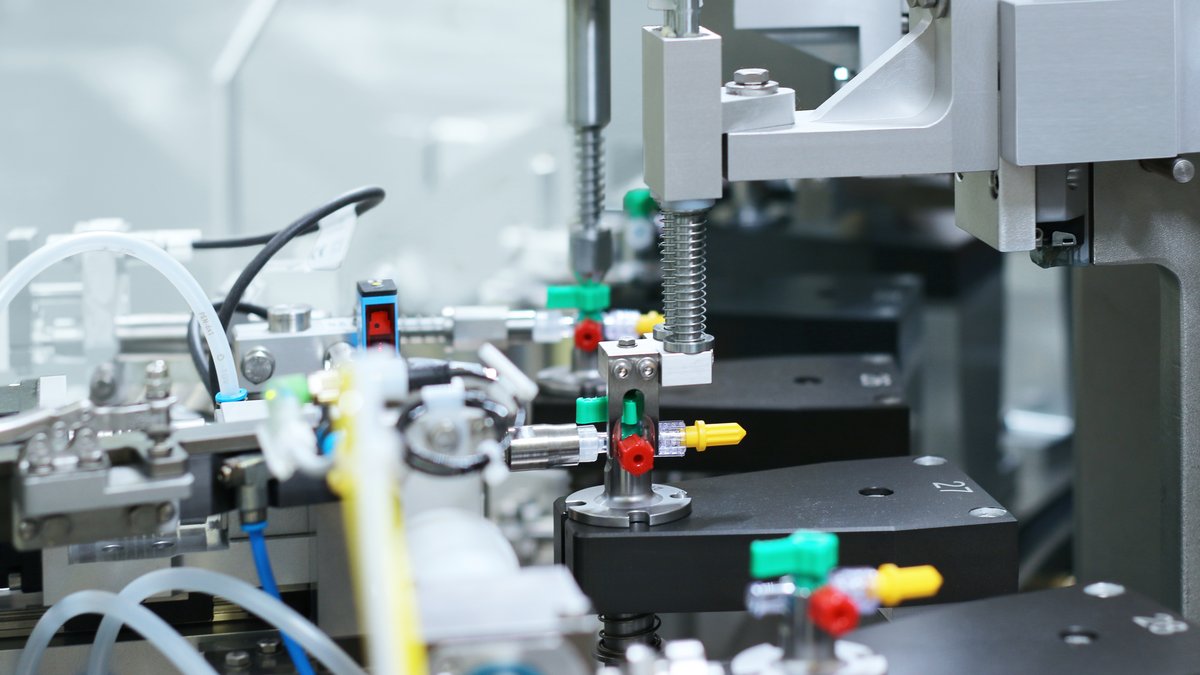

Implemented processes

Especially also for hoses and flexible parts

- Riser assembly

- Ultrasonic welding

- Sophisticated joining processes

- Complex screwing processes

- Filling

- Siliconisation

- Solvent application

- Leak test

- Flow test

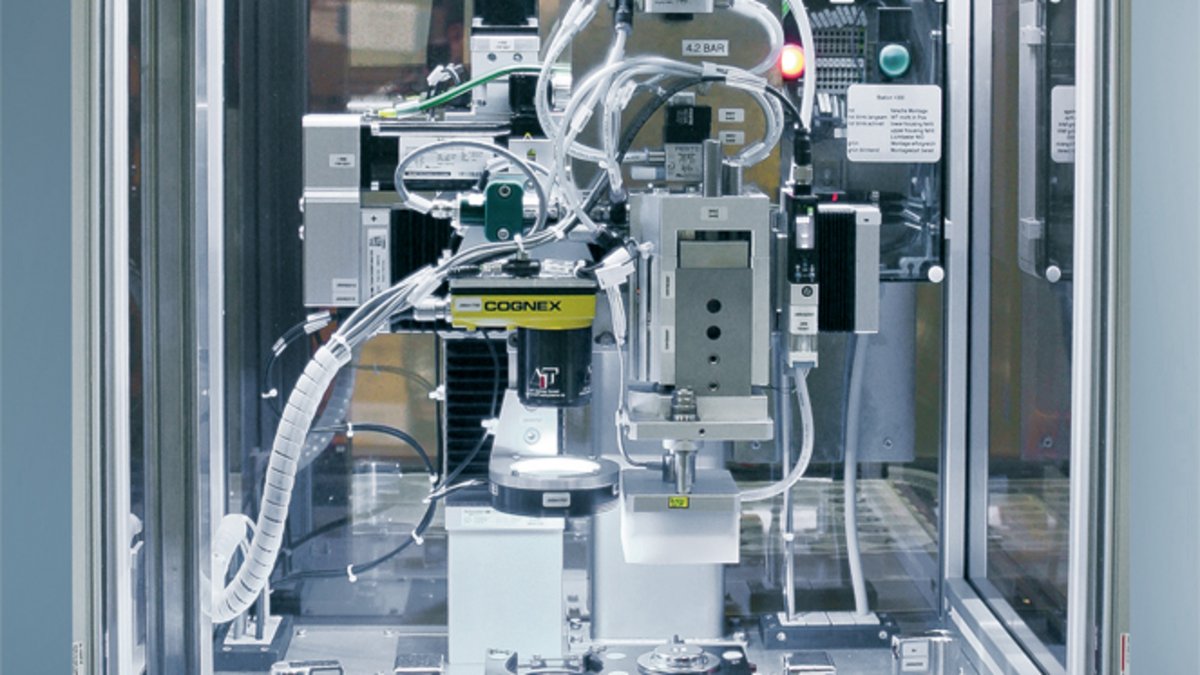

- Function test

- Visual inspection

- In-house feeders

- In-house palletisers

- Coiling process for hoses

- and many other processes

TEAMED RTS for disposables

The ideal machine platform and mass production superstar.

The fastest assembly system from BBS helps to reduce production costs. The high-speed RTS system assembles up to 500 plastic assemblies per minute and over 100 variants - and more if required.

- High-speed with up to 120 cycles/min.

- Stable processes

- Compact design for up to 40 stations

- Only one servo drive and few pneumatics

- Low maintenance and low operating costs

- Large product variance possible

- Cost-efficient production

Numerous product variants?

The solution is here.

Many of our customers produce up to 40 product variants on the same TEAMED RTS. This production system is so flexible that it can be set up for a new variant economically and easily. The short set-up times don’t come at the expense of cycle time - a big cost advantage.

Our applications

Because all services are provided by one single company:

Why BBS?

BECAUSE ALL SERVICES ARE PROVIDED BY ONE SINGLE COMPANY:

- Assembly and testing technology

- GMP-compliant system platforms

- Feeding technology

- Palletiser/tray loader

- Software

- Qualification

Get in touch with our experts

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Influence of Machine Concepts on overall Equipment Effectiveness - EN

PDF / 2.03 MB

Influence of Machine Concepts on overall Equipment Effectiveness - EN

PDF / 2.03 MB