Automation Systems for Petri Dishes

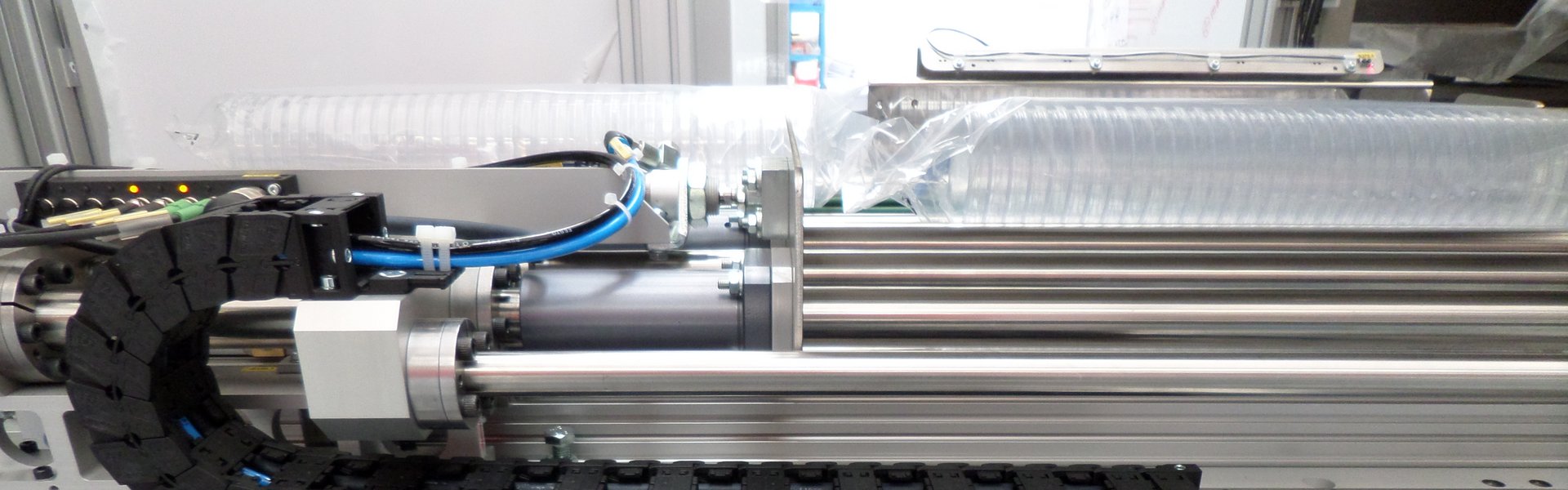

With production volumes in the millions per year, a high-quality automation system is needed in which quality and productivity work hand-in-hand. Petri dishes are produced in clean rooms. Contact with humans must be kept to a minimum. What sets a high-performance automation system apart is its high level of availability and consistency in product quality.

With HEKUdish we offer a platform that fully meets all current market requirements for processing Petri dishes.

With a flexible design the system can be configured for specific products such as Contact Dishes and Cell Culture Dishes, providing you with a customized solution with maximized productivity and efficiency. The standard solution can be combined with various molds and injection molding machines from 2+2 to 16+16, from semi-automated to fully-automated.

Your advantages at a glance:

- Flexible use for all Petri dish diameters and packaging units

- Scalability from small batch production (PetriLite) up to 90 million parts/year

- Fulfillment of quality and cleanliness requirements with full traceability

- Consistently high product quality

- Very high production output with excellent system availability

- Concept also applicable to other products such as contact dishes or cell culture dishes

Here you find our flyers for download:

HEKUdish compact

PDF / 475.25 kB

HEKUdish compact

PDF / 475.25 kB

HEKUdish next Gen

PDF / 621.38 kB

HEKUdish next Gen

PDF / 621.38 kB

Markus Porath

Would you like to contact BBS Automation online?

Then use our online contact form!

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!