“Vocational training has always been a high priority at Dürr as company with a long tradition,” said Group CEO Dr. Jochen Weyrauch at the official opening. He described the approximately 1,000-square-meter vocational training center as an “important investment in the two sites of Bietigheim and Freiberg, as well as in Germany as a business location, to which we are committed.” At the same time, the Dürr Group was thereby sending a clear signal to young professionals: “We need you, and we are investing in you!”

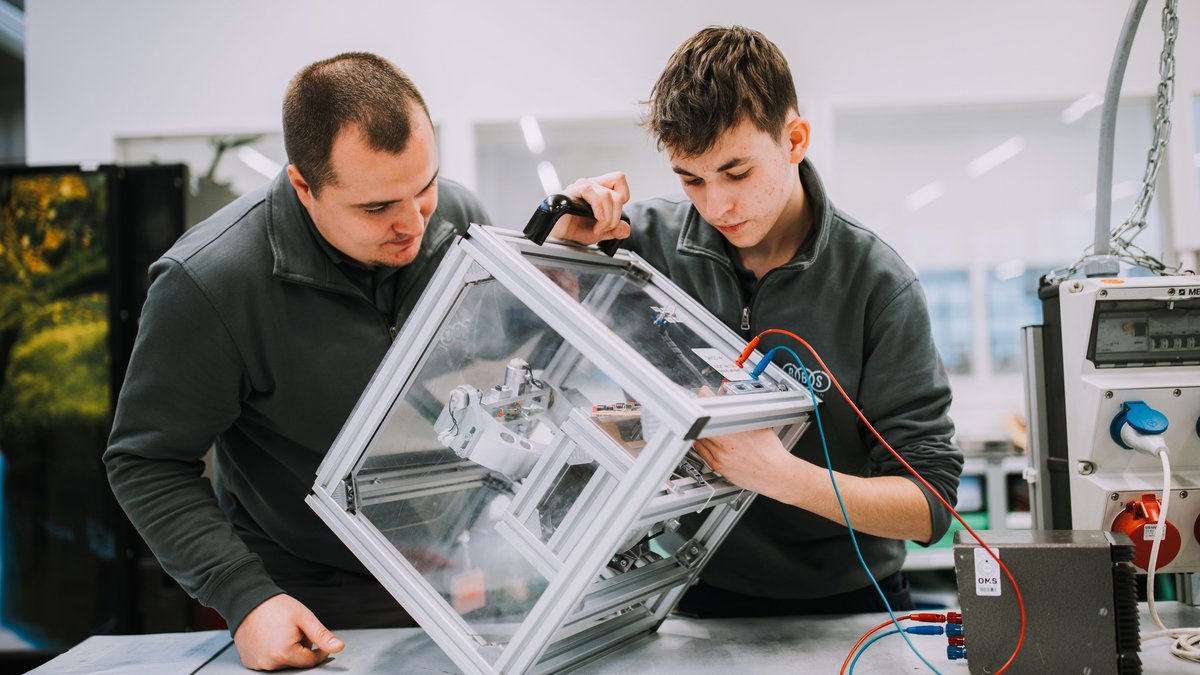

Since the beginning of this year, Dürr Systems and BBS Automation have modernized the machinery and training infrastructure. The apprentices have access to expanded possibilities for working with modern technologies, such as 3D printing. The vocational training team, led by Uwe Klaiber and Marcel Rütten, as well as the apprentices themselves were actively involved in the planning process from the outset. At the start of the training year on September 1, and thus right on schedule, the joint vocational training center was completed.

Getting to know two companies at once

Currently, 127 young people are preparing for their professional careers here. They benefit from uniform training standards and the chance to collaborate in an even larger team. After all, they gain a wide range of insights into two companies at once: At BBS Automation in Freiberg, they learn about special machine construction. This involves manufacturing customer-specific automation solutions, for example for the assembly of electric drives, solar modules, and infusion sets. At Dürr in Bietigheim, apprentices are familiarized with the series production of painting robots.

Dürr Systems and BBS Automation currently employ 74 apprentices and 53 students in work-study programs. The training programs offered by both companies comprise nine vocational training courses, ranging from specialized computer science to industrial mechanics and warehouse logistics. In addition, there are 12 work-study programs to choose from, including automation technology, mechanical engineering, and business engineering. In total, the Dürr Group currently trains 525 young people in Germany.

The Dürr Group is one of the world's leading mechanical and plant engineering firms with particular expertise in the technology fields of automation, digitalization, and energy efficiency. Its products, systems, and services enable highly efficient and sustainable manufacturing processes – mainly in the automotive industry, for producers of furniture and timber houses, as well as in the assembly of medical and electrical products and in battery production. The Dürr Group generated sales of €4.7 billion in 2024 and currently has around 18,000 employees and 130 business locations in 32 countries. Since the sale of its environmental technology division at the end of October 2025, the business has been consolidated into three divisions:

- Automotive: painting technology, final assembly, testing and filling technology

- Industrial Automation: assembly and test systems for automotive components, medical devices, and consumer goods as well as balancing technology solutions and coating systems for battery electrodes

- Woodworking: machinery and equipment for the woodworking industry