Efficient Equipment for more Stability and Reliability

For the postprocessing of cast components BBS supplies the necessary equipment, such as efficient machines with large cutting volumes (roughing equipment), large opening distances and long punching strokes, as well as machines for cutting chips of castings.

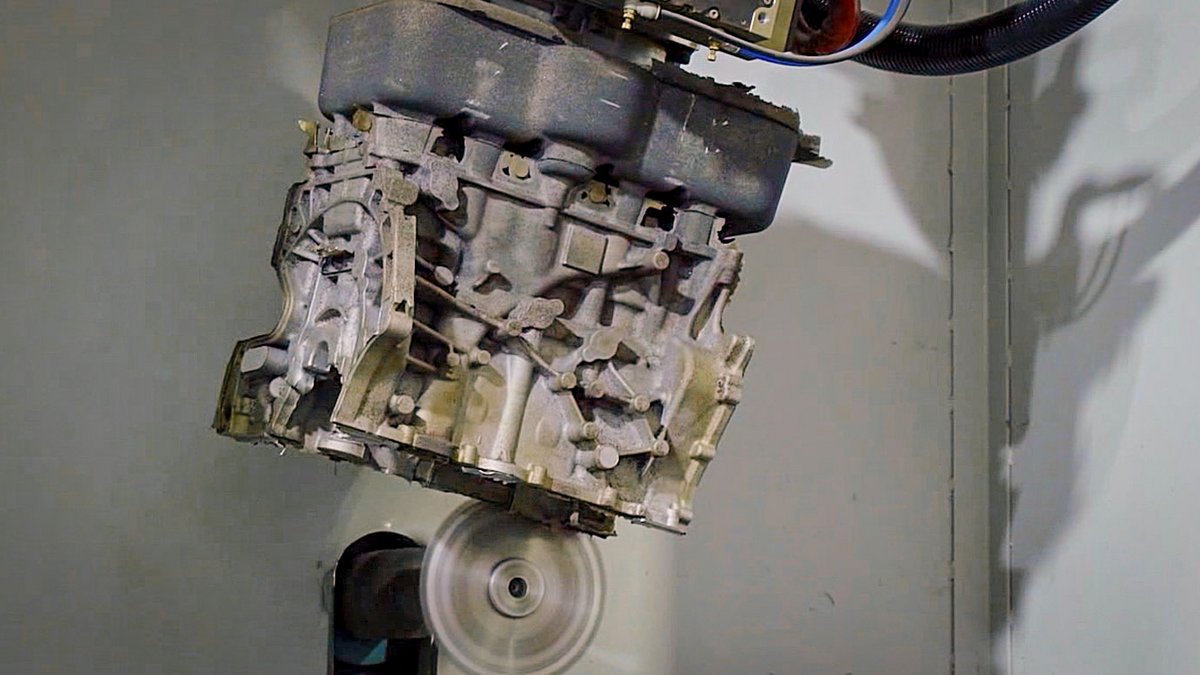

Deburring machines

BBS machines for removing burrs from castings are designed so flexibly that different products can be realized. Robots are used to load and unload the machines.

Sawing and drilling machines

BBS machines can be designed as multi-functional systems.They are used for sawing off or removing feeders and risers, for cutting through multiple die parts and for pre-drilling, all in one and the same machine.

Facts about Trimming & Machining

- Solid mechanical structure

- Large opening distance and stamping stroke

- Rapid mold change design

- Easy maintenance and overhaul

- More energy saving and efficient

- Industry-leading cutting and machining speed

Our Advantages

- Wide experience and various product range

- Global footprint of BBS

- Multilingualism of employees

- Tailored, customer-oriented solutions

- Optimized build times with 100% monitoring, reliability, quality

- Global project management and service support

- A key account team conducts each project

Trimming

Efficient processing of batch products

Sawing

Non-standard design to meet the demand of flexible production

Drilling

Fast on-line rough machining of casting, reduce finishing workload and cost

Key Features and Advantages

Deburring machines

- Robust mechanical structure ensures stable and reliable running performance and convenient maintenance.

- Quick mold change design, mold change can be completed quickly through forklift or mold change support

- The pump unit with servo motor is more energy-saving and efficient than the conventional setup consisting of mains frequency motor and load-dependent variable pump.

- Industry-leading blanking speed, shorten cutting time and improve production efficiency;

- The position of the moving template can be freely programmed, and the repeated positioning accuracy can reach ±0.5mm.

- User-friendly user interface, easy to program and equipped with fault analysis

Sawing & Drilling machines

- Solid machine frames ensure stable operation and low vibration.

- Saw precision: size tolerance ±0.5mm, shape tolerance flatness < 0.6mm

- Drilling accuracy: diameter tolerance: ±0.5mm, hole position < 0.6mm

- Cutting speed: 871-1750rpm, the speed is adjustable

- Quick fixture change design, can be completed quickly through forklift or hoist.

- User-friendly user interface, easy to program and equipped with fault analysis

Downloads

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB