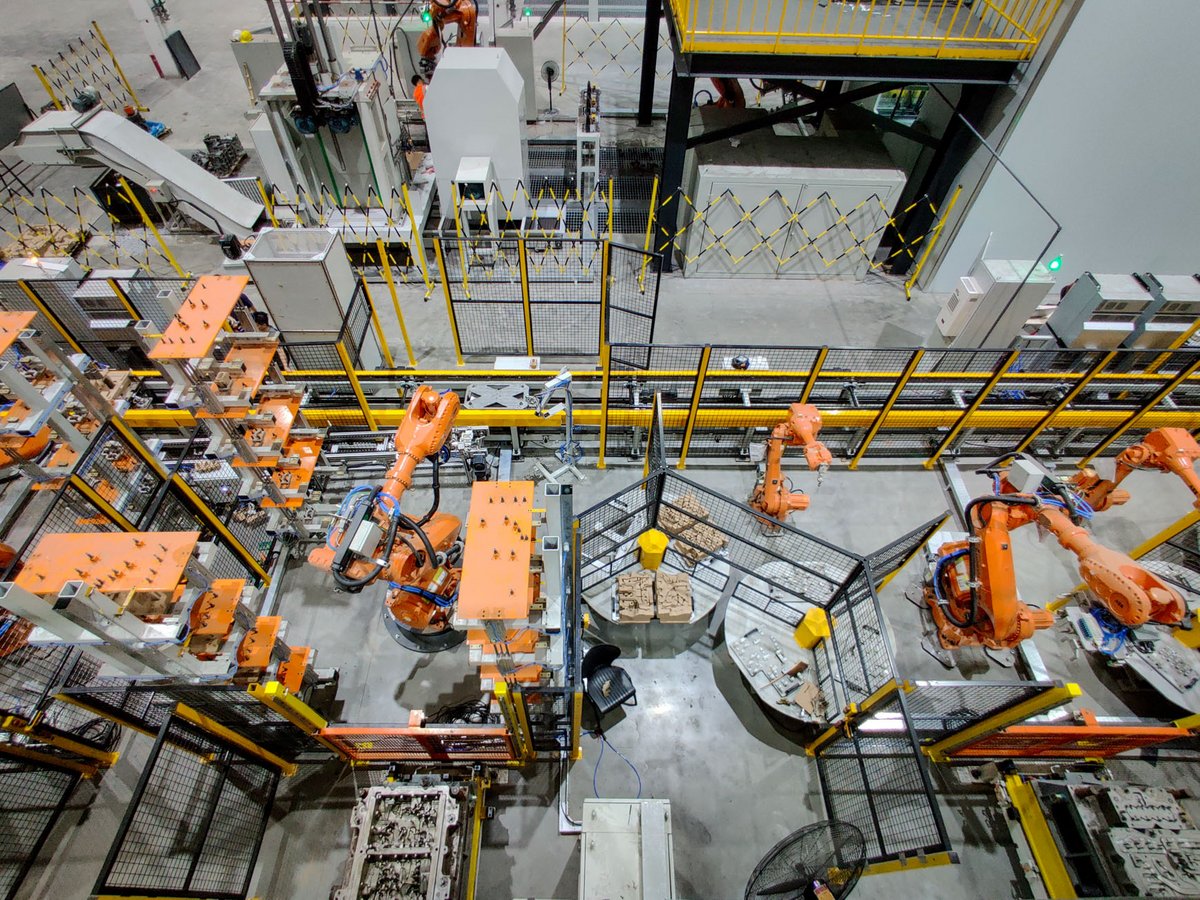

Comprehensive Automation for Core Making

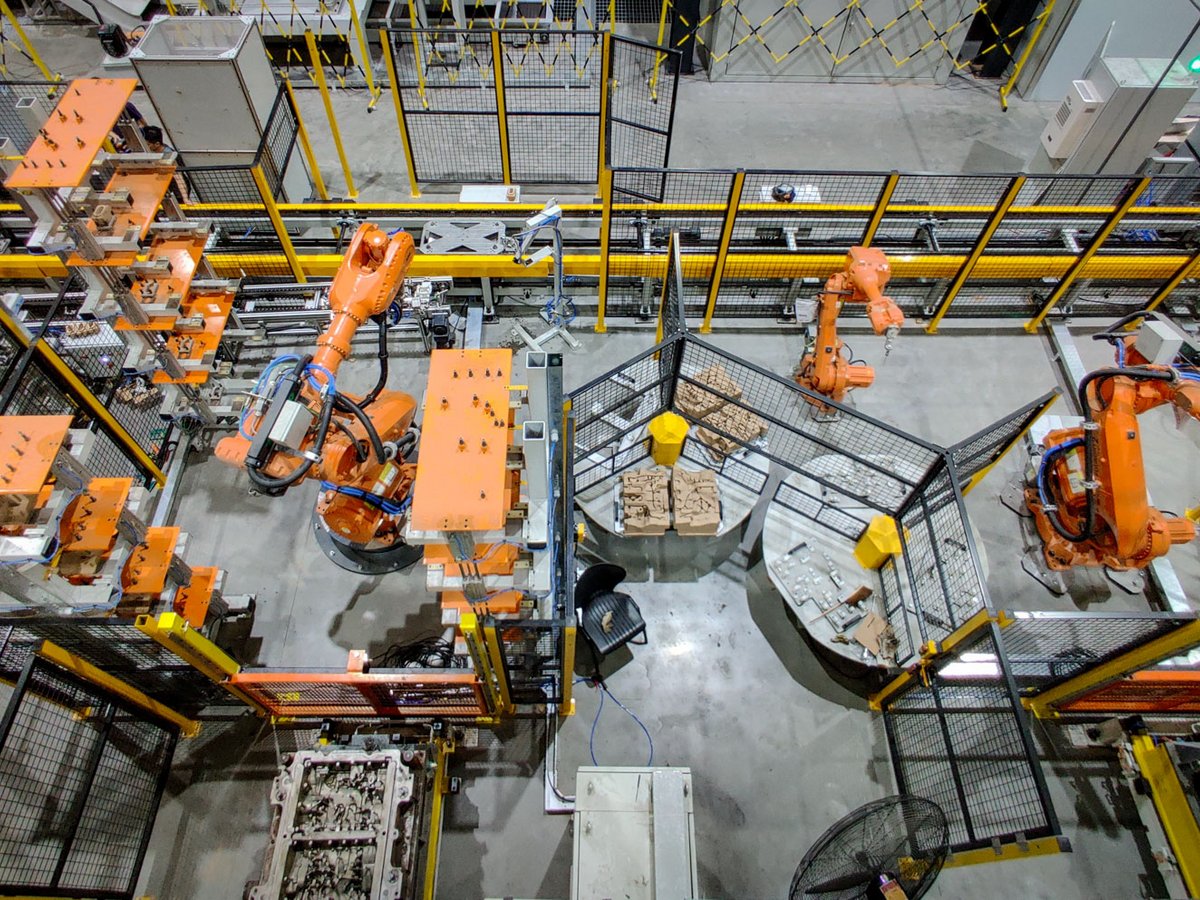

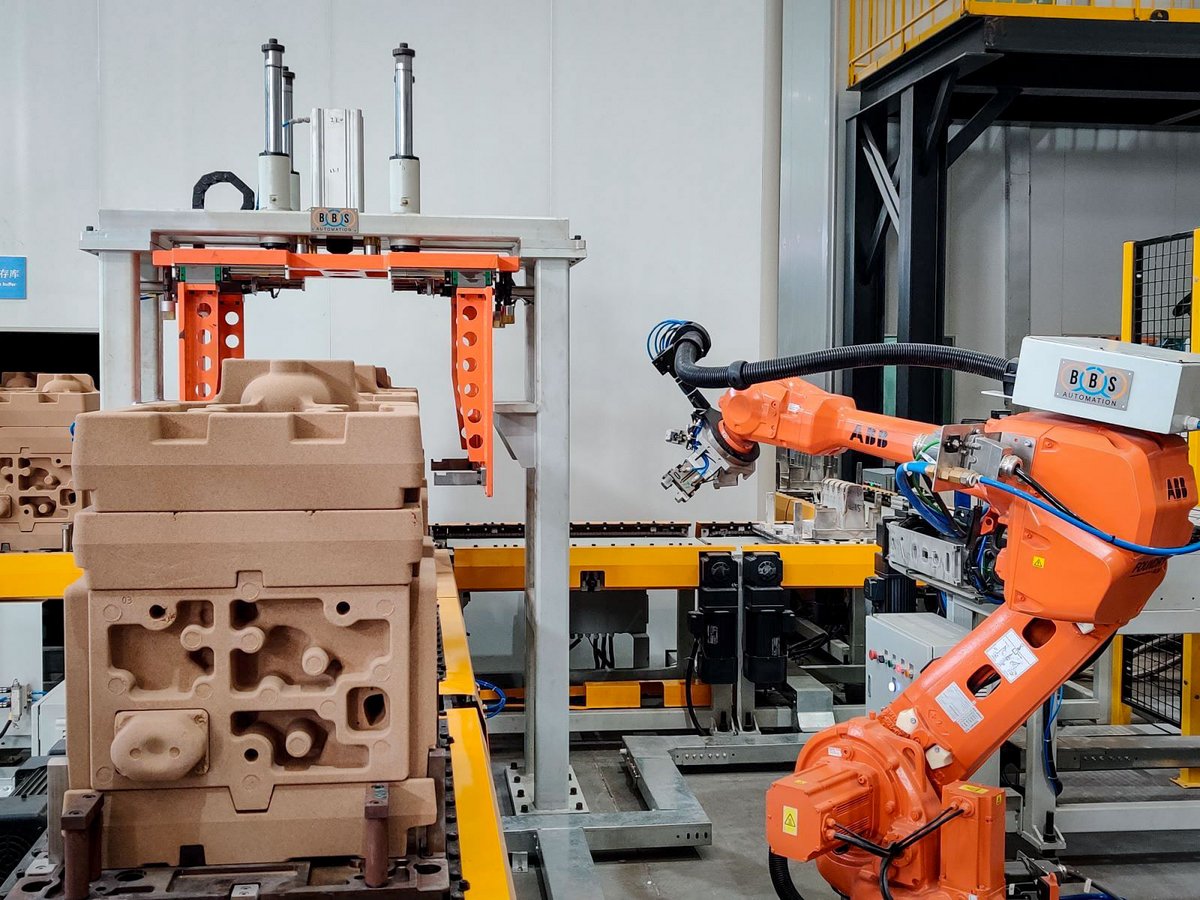

The automated BBS systems for core production are used, for example, in the manufacture of large castings such as engine cylinder blocks or cylinder heads. Here, all relevant processes are connected with each other to form an organic production line.

BBS offers flexible and customized overall turnkey concepts. For example, the following processes and stations can be integrated in one production line: Core removal, deburring, dip coating, drilling, core assembly, bonding, core inspection, storage, transport, etc.

Facts about Die Casting

- Experience in various casting processes

- Customized according to product, process and planning

- Meet the demand of flexible production

- The design adapts to different working conditions

- Complete turnkey project including product, mould, waste disposal, etc.

Our Advantages

- Wide experience and various product range

- Global footprint of BBS

- Multilingualism of employees

- Tailored, customer-oriented solutions

- Optimized build times with 100% monitoring, reliability, quality

- Global project management and service support

- A key account team conducts each project

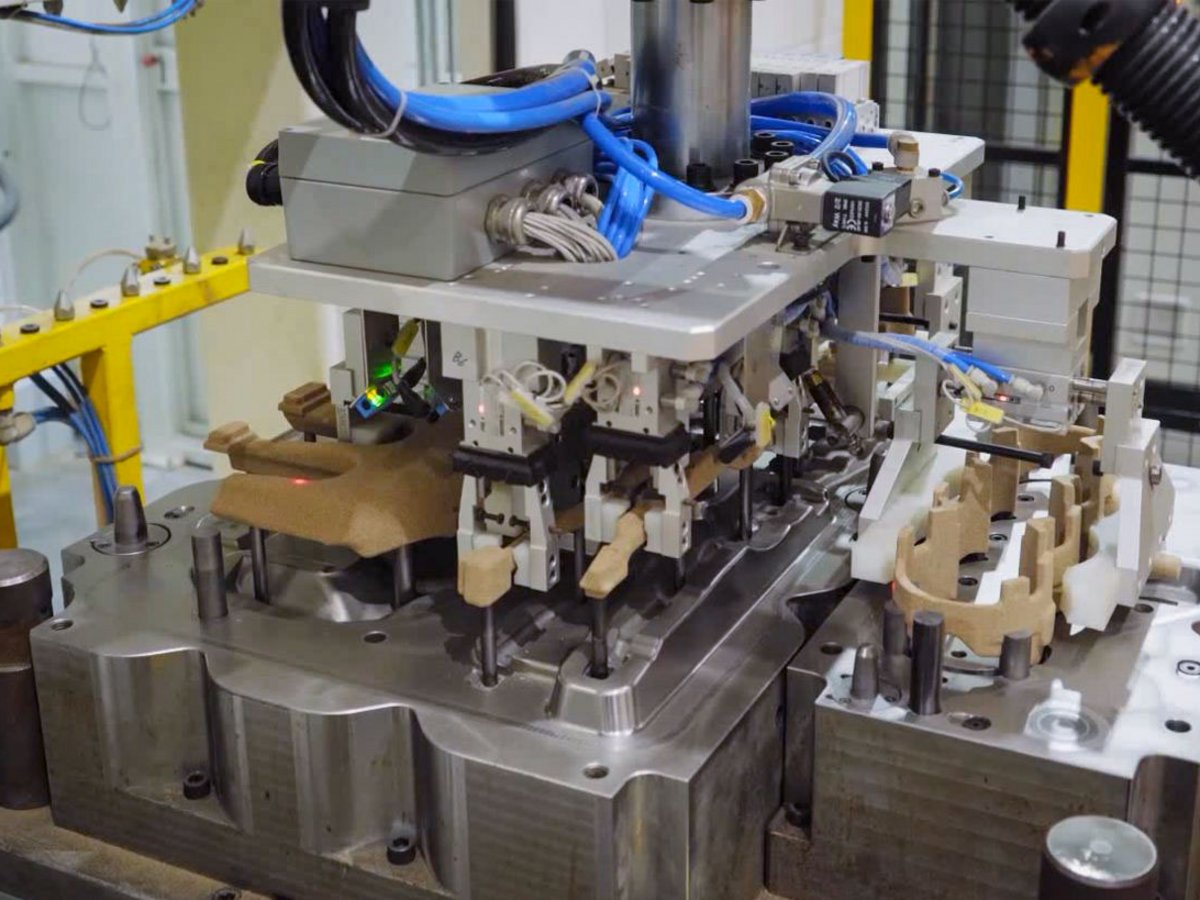

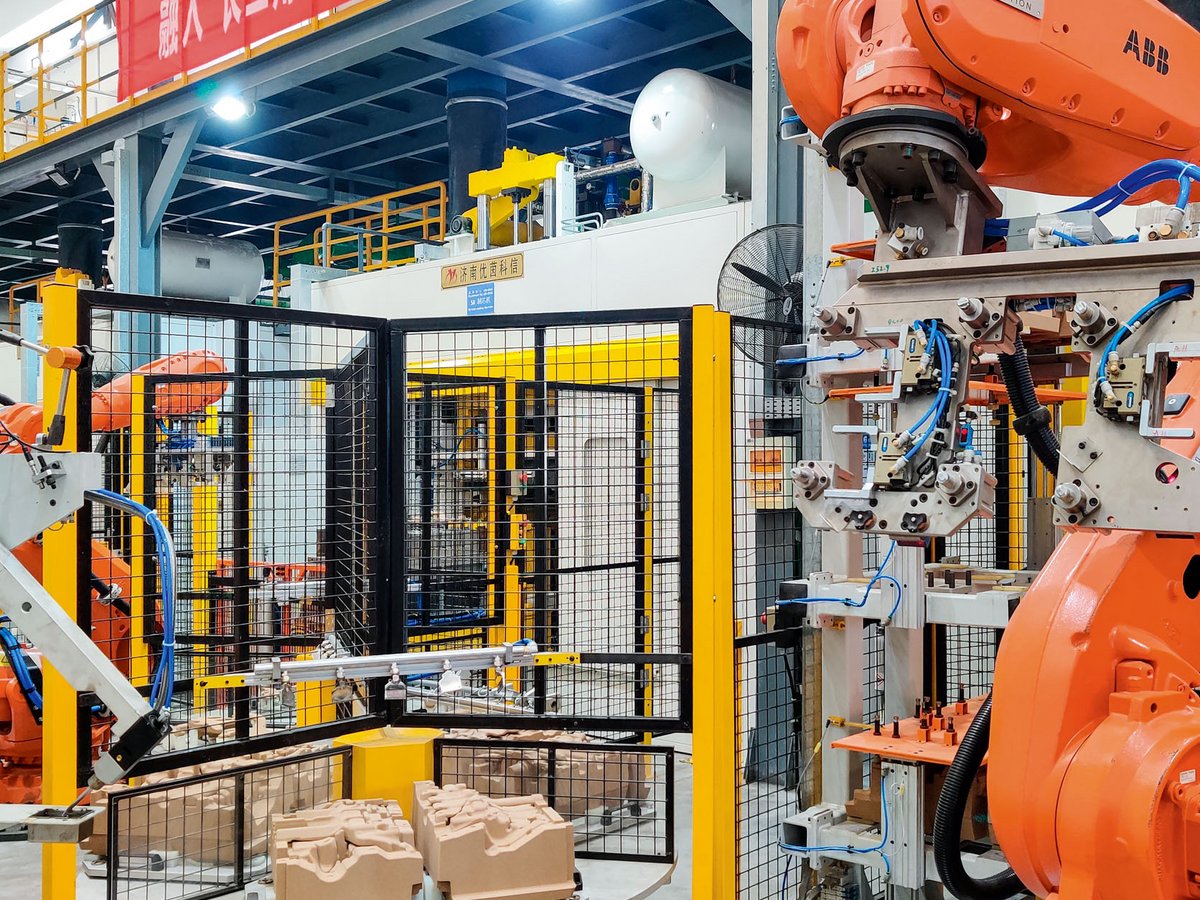

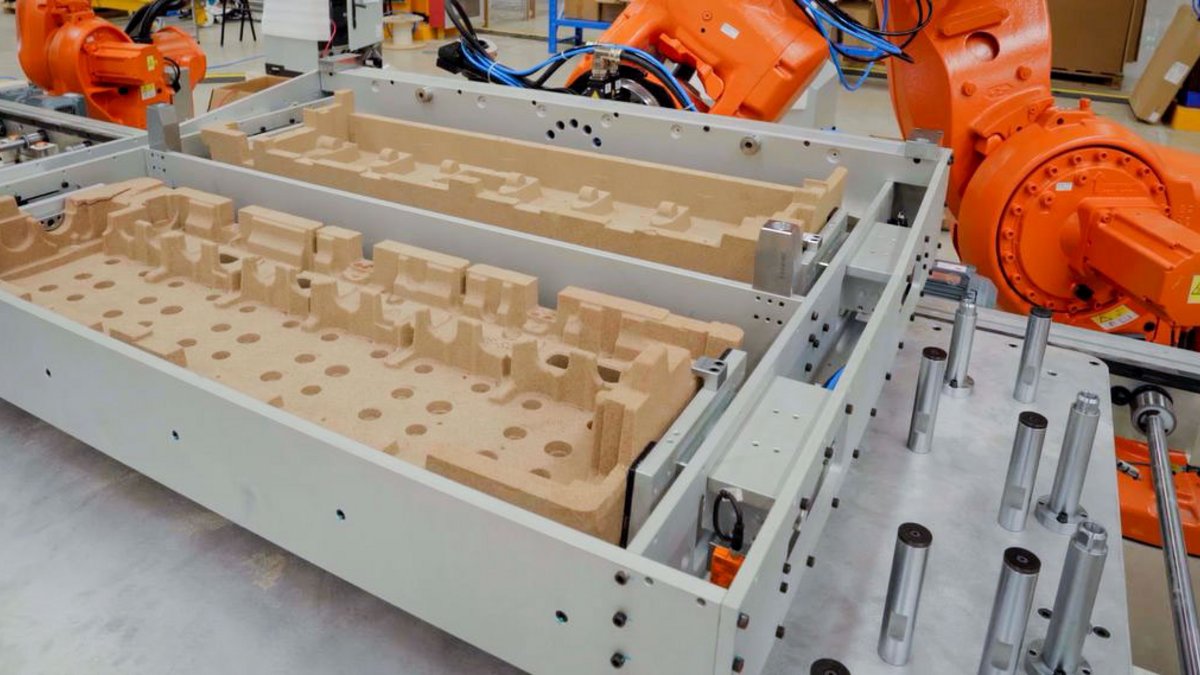

Core Handling

Systems for precise and efficient core removal or core insertion

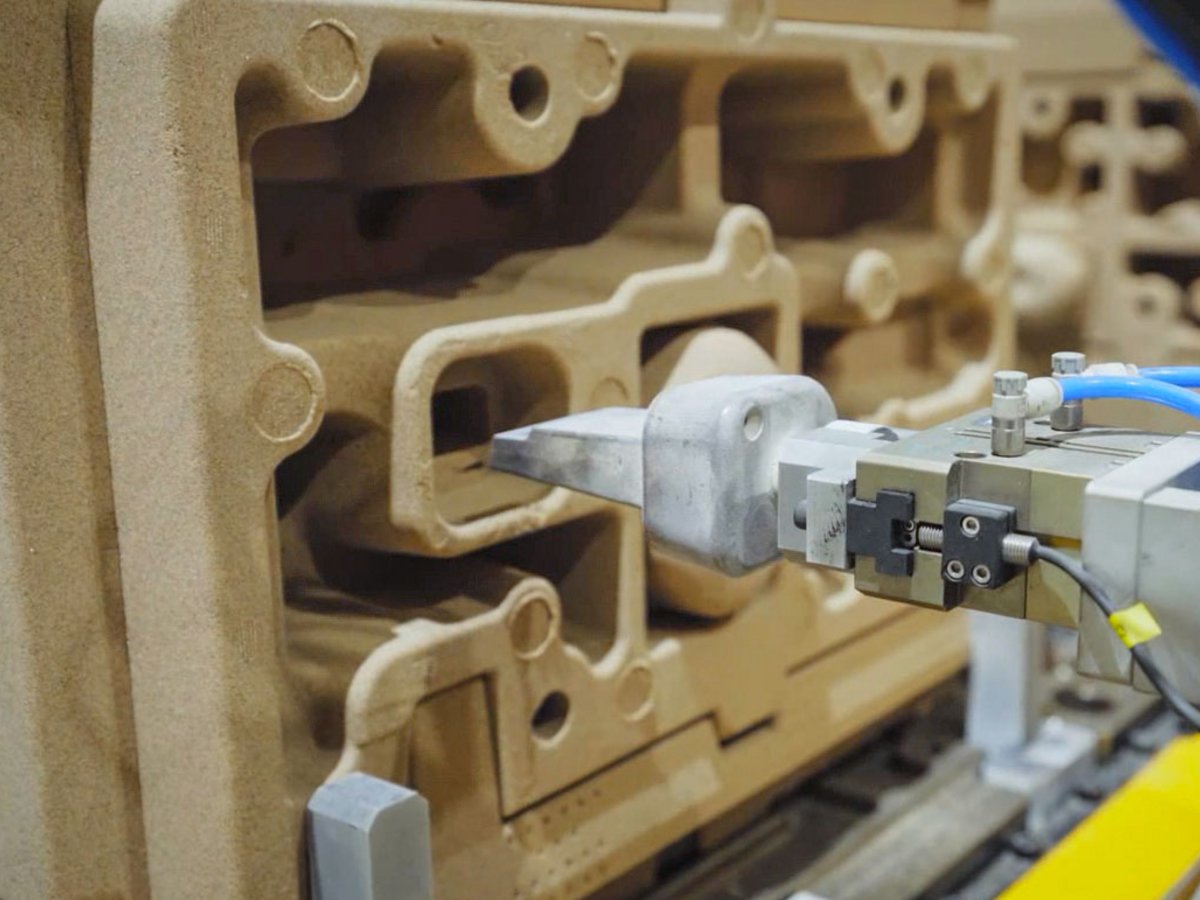

De-burring, coating

Pretreatment of sand core before assembly

Assembly

Integration of the technology in the core manufacturing unit or production line

Core gluing

Fixing solutions include gluing, nail shooting, screwing and bolt fixing, etc.

Key Features and Advantages

- Efficient layout, with low space requirements

- Structural features of the machines and components, specially designed for foundry conditions, ensure stable running, low failure rates and short cycle times.

- Flexible design - quick gripper and fixture change - more than two types parts can be produced in one line

- The technology provides a high level of dimensional accuracy with high process stability.

- User-friendly user interface, easy to program and equipped with fault analysis

- RFID is used to track sand cores in real time. MES is used to collect, summarize and analyze production process data and can be connected with customer ERP system.

Downloads

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB