The importance of diagnostic devices and the automation required to manufacture them is more critical today than ever before. As Point-Of-Care-Testing (POCT) have evolved so have the tools used for diagnostics. What once may have been a simple test strip has now turned into an electronic device that can take a blood sample and perform the diagnostic in one simple step. To meet the requirements of these complex disposables, BBS has been able to provide high speed automation solutions for the micro components used in these electronic devices.

Implemented processes

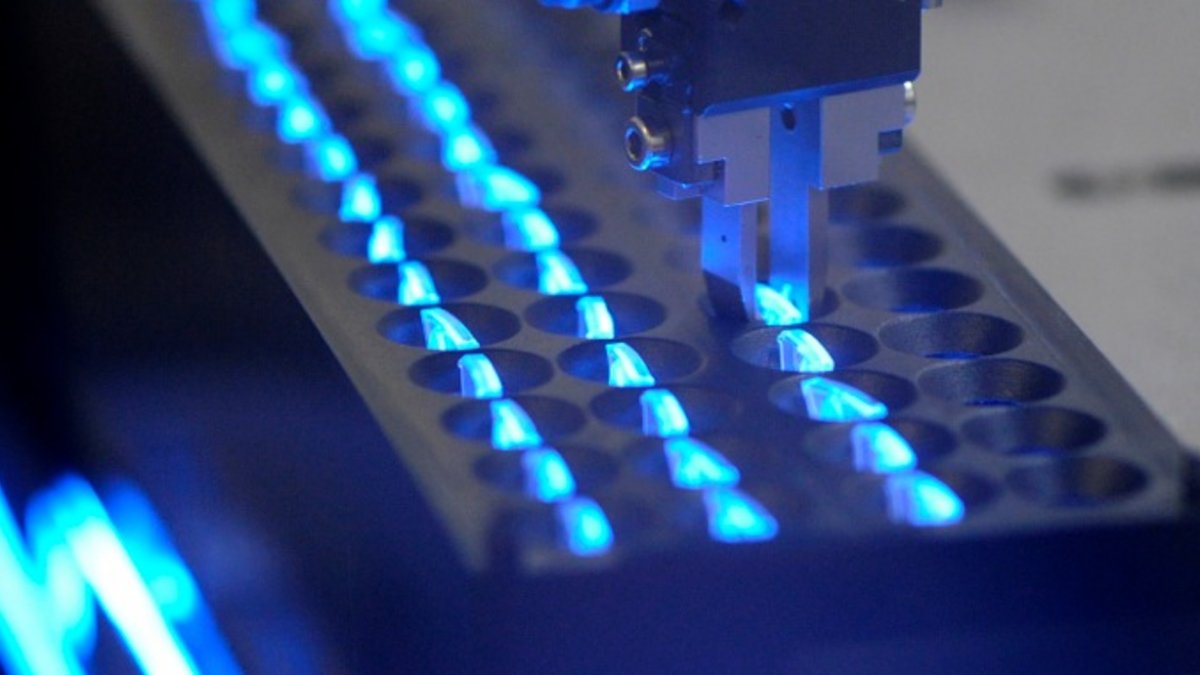

- Biomarker spotting

- Plasma surface treatment

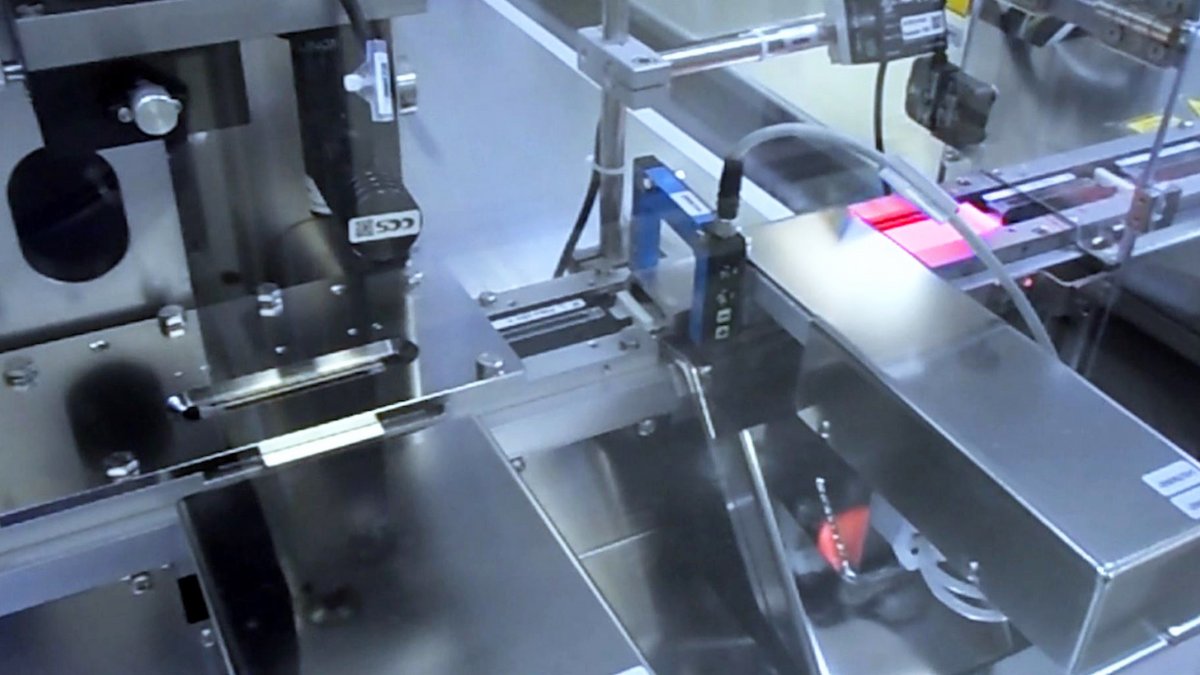

- Image processing

- Ultrasonic welding

- Laser welding of plastics

- Laser inscription

- Bonding with UV curing

- Microdosing

- Camera control

- Drying processes

- Blister feeding

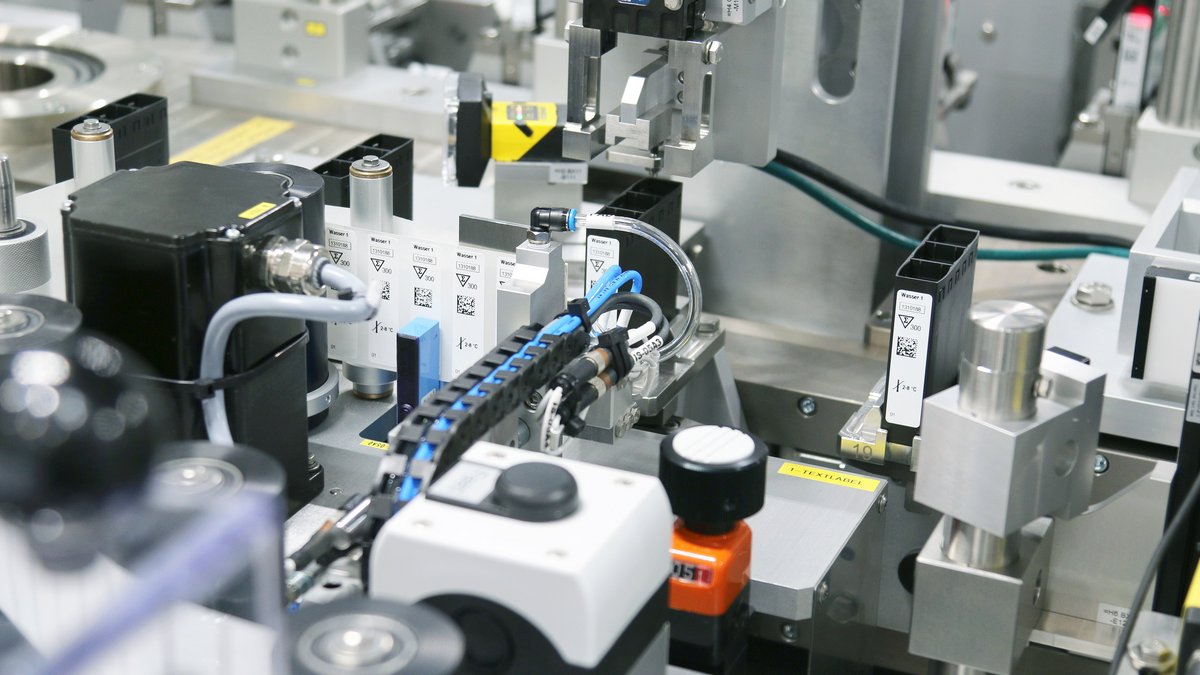

- RFID labelling

- Leak test

- In-house feeding technology

- In-house palletising systems

- and many other processes

Our applications

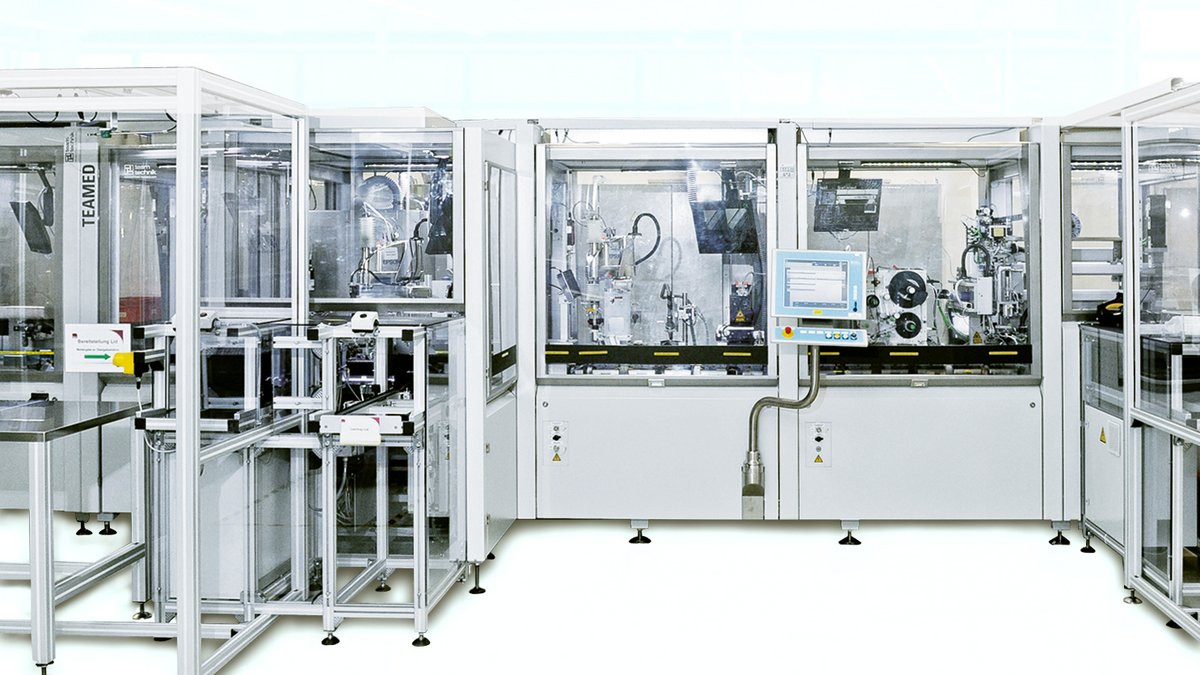

Flexible assembly line for diagnostic cartridges

Suitable for Covid 19 antibody tests. Extremely low error rates in final processing. The system ran trouble-free from the first day of the FAT with the highest throughput.

ASSEMBLY LINE FOR DIAGNOSTIC LABORATORY MATERIAL

Flexible high-performance system for the production of disposable medical rapid tests in various product sizes.

Local for local.

Assembly line for diagnostic cartridges for the Chinese market. Short delivery times thanks to project management at our Chinese production site.

Proof of Principle SOLUTION

Semi-automatic blister assembly of devices for sepsis diagnostics

Assembly and testing line for diagnostic cartridges

For HIV testing with 100 percent inline testing. The complex assembly solution guides the customer step by step from manual sample assembly to reliable batch production.

Why BBS?

Because all services are provided by one single company:

- Assembly and testing technology

- GMP-compliant system platforms

- Feeding technology

- Palletiser/tray loader

- Software

- Qualification

Get in touch with our experts

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Influence of Machine Concepts on overall Equipment Effectiveness - EN

PDF / 2.03 MB

Influence of Machine Concepts on overall Equipment Effectiveness - EN

PDF / 2.03 MB