The Most Sensitive Way to Detect Leaks

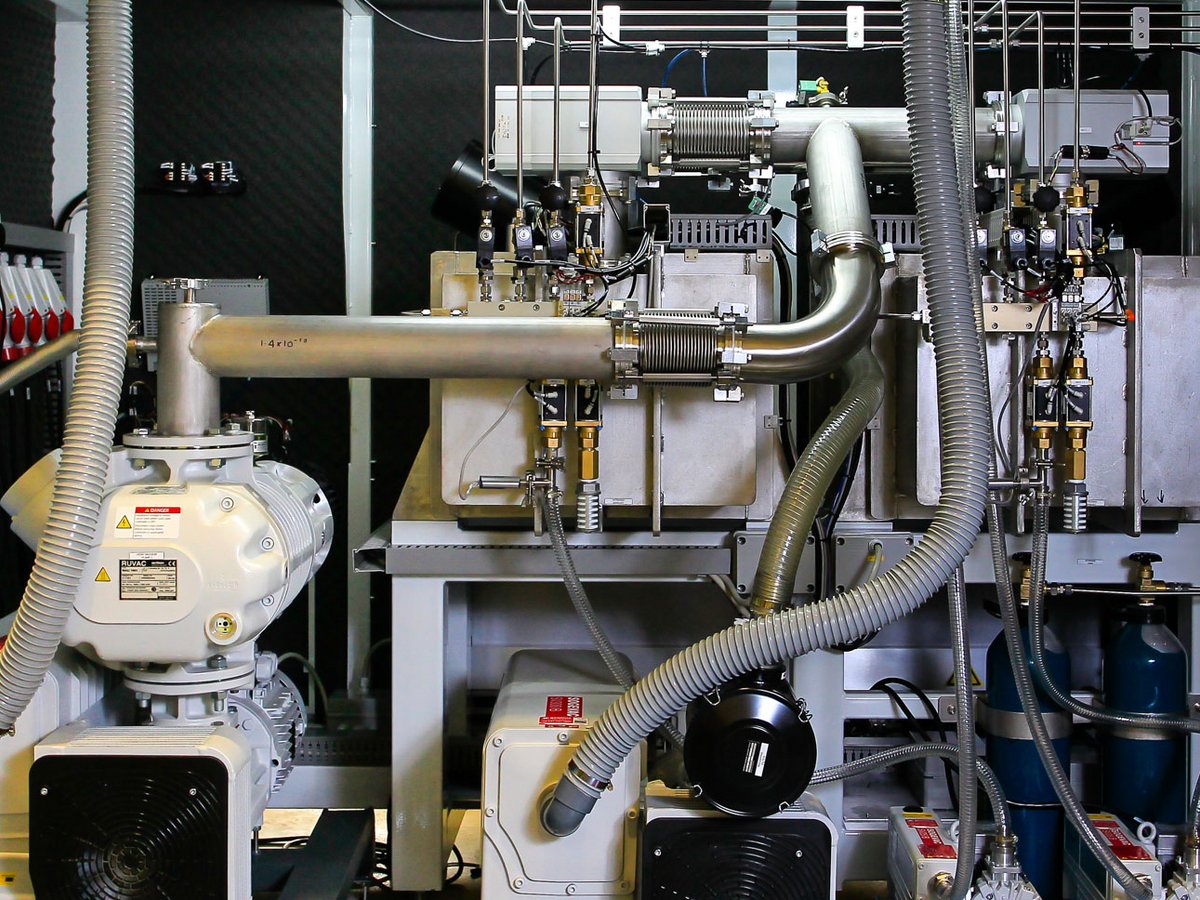

Helium leak detection systems (HLDS) are most sensitive. Our helium leak detection systems check parts and devices for the smallest flaw. They offer the perfect combination of highly advanced leak detection features plus uncompromised industrial flexibility and durability for high-vacuum applications.

The advantages of the BBS-HLDS, whether integrated into an assembly line or as a stand-alone unit, lead to faster test and assembly cycles, higher quality levels, and better process reliability — improving product quality.

Why do we use helium to locate leaks? Helium has many advantages. It occurs only in low concentrations in the ambient air and can easily be detected. Helium is non-toxic and does not react with other materials. The small atomic radius enables quick tests and the detection of even the smallest leaks. Additionally, our special helium recovery systems help to reduce emissions and costs during production.

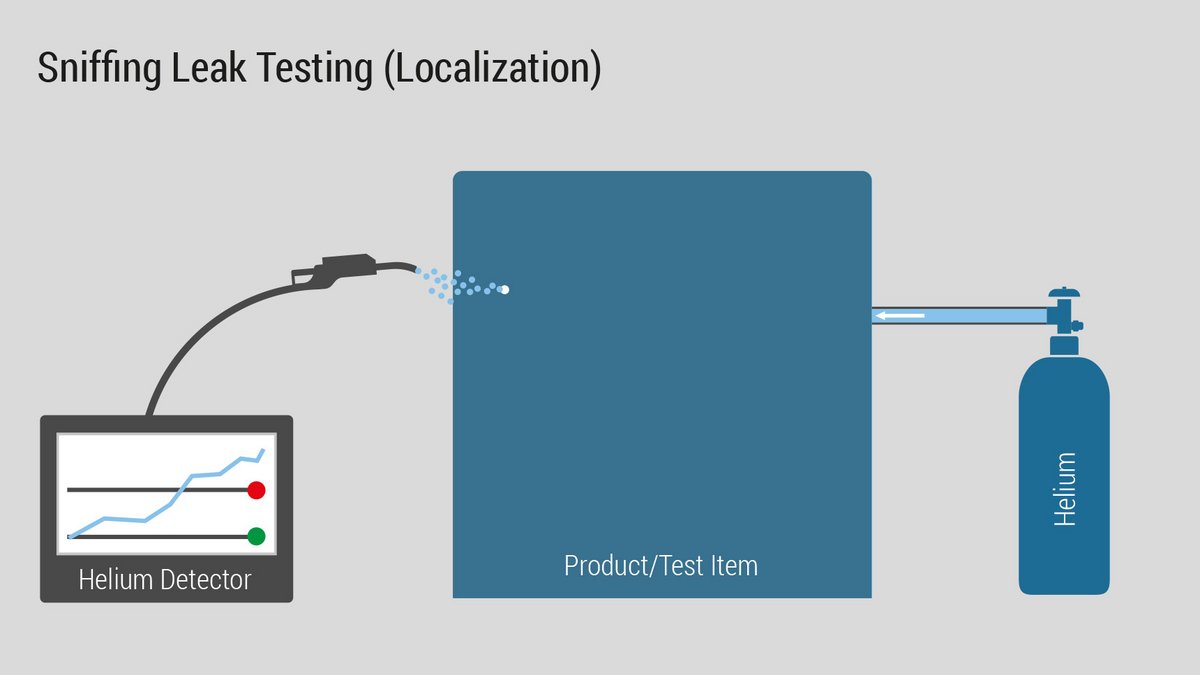

Sniffing Test

The product is filled with helium. In case of leaks the gas escapes through the leakage channel and is detected by a sniffer probe. The probe can be moved manually or automatically via a robot.

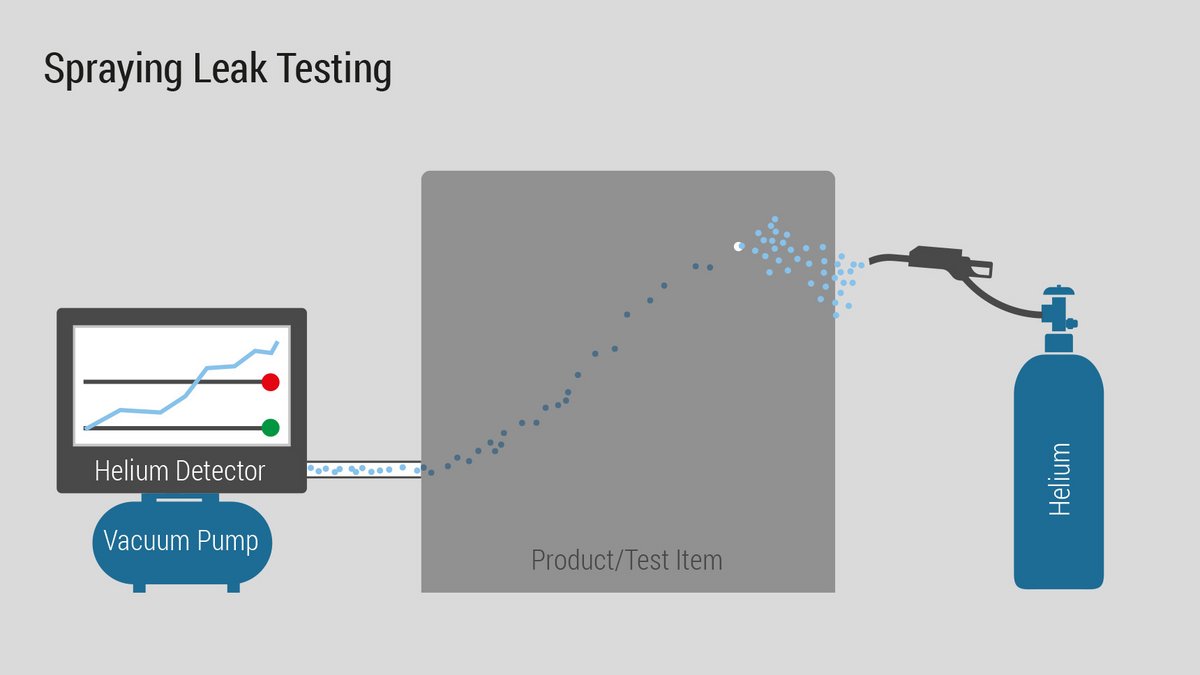

Spraying Test

First a vacuum is created in the product. The tracer gas is distributed over the product with a spray probe and can penetrate the leak.

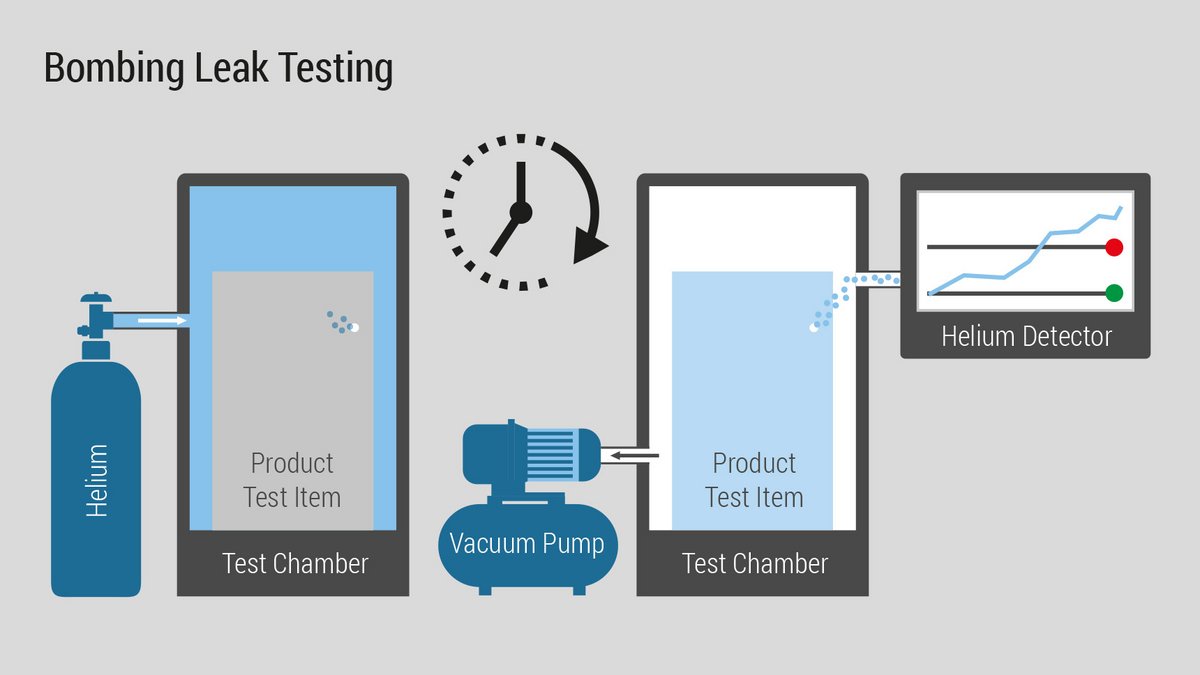

Bombing Test

The method is used for products that cannot be connected directly to a leak detector. The product is placed in a chamber containing pressurized helium. The helium penetrates into the product. The actual test then takes place in the vacuum chamber, to which a helium detector is connected.

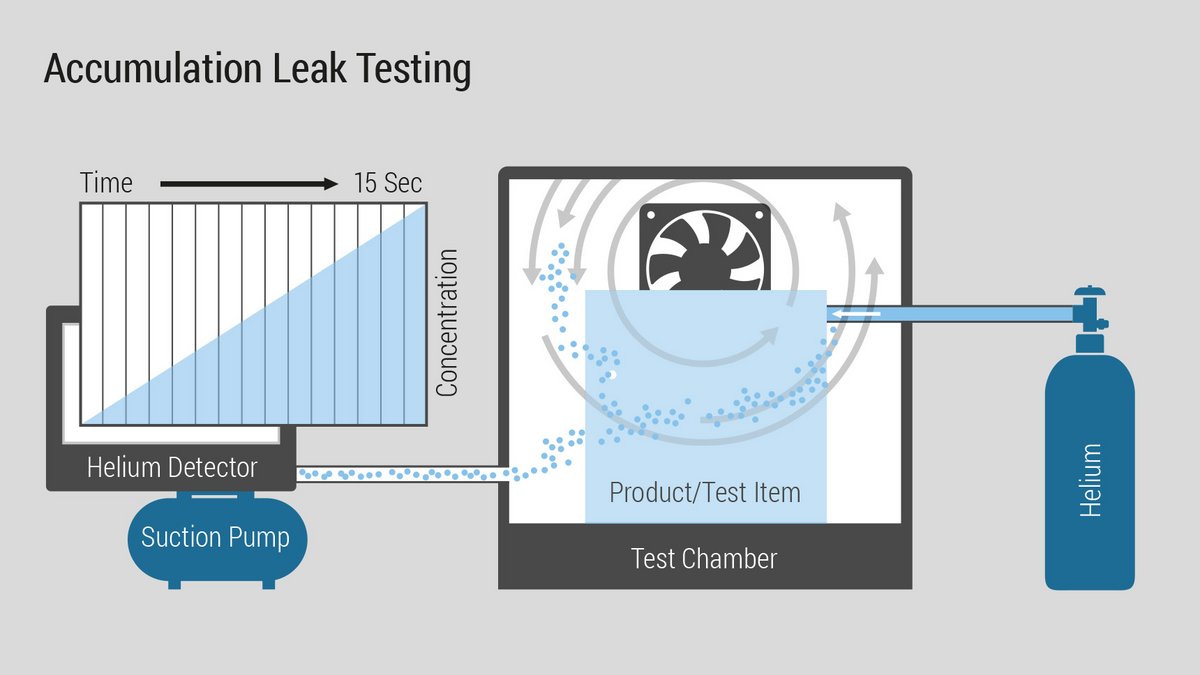

Accumulation Test

The product is placed in an accumulation chamber and filled with tracer gas. Gas which escapes through leaks is equally distributed throughout the chamber via fans. The leak detector measures the total leakage rate of the test item.

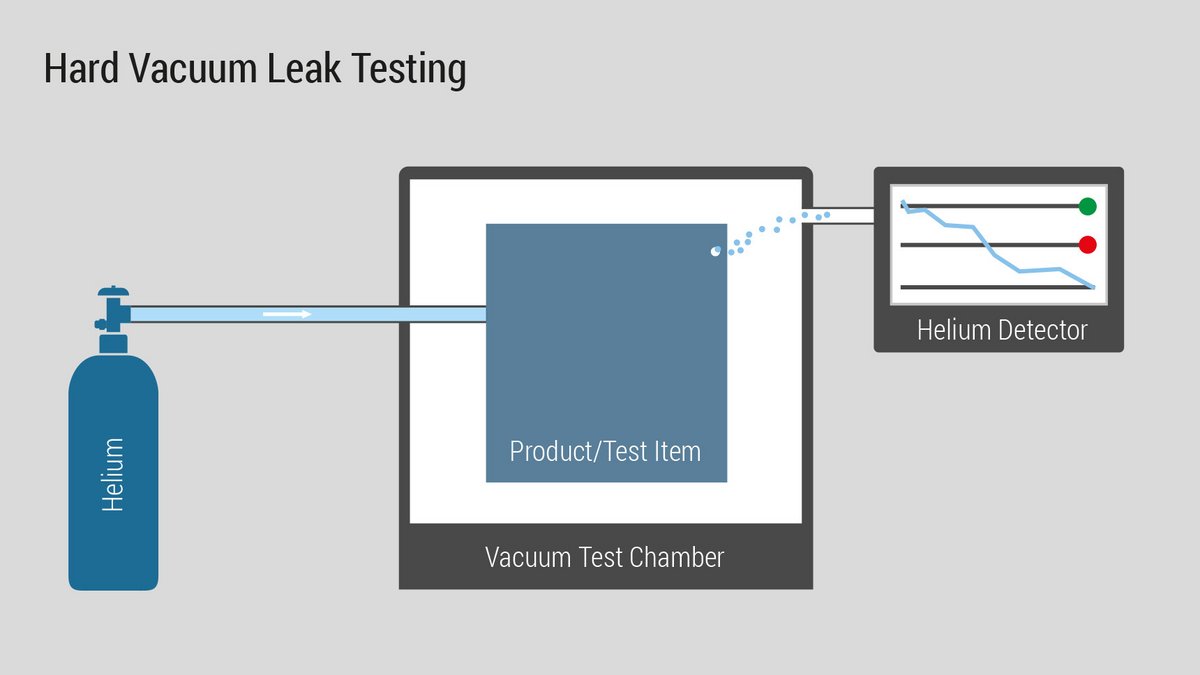

Hard Vacuum Leak Test

The product is filled with helium in an evacuated vacuum chamber. In case of a leak, the gas escapes through the leak and is measured by a helium leak detector which is connected to the vacuum chamber.

Short facts about HLDS from BBS

- Ability to provide the customer with a total solution, from assembly to the testing process

- Customized and compact design

- Systems with highest sensitivity

- Single frame, stable and easy to relocate

- Automatic calibration

- Optional heating device to prevent moisture from affecting cycle time

- Two pumping lines (pre-vacuum and high vacuum)

- Dedicated filters for vacuum or high pressure line

- Built-in sniffing systems to locate leaking helium lines

- Automatic depollution with nitrogen

Our Advantages

- Wide experience and various product range

- Global footprint of BBS

- Multilingualism of employees

- Tailored, customer-oriented solutions

- Optimized build times with 100% monitoring, reliability, quality

- High productivity, operating 24/7

- Global project management and service support

- A key account team conducts each project

Downloads

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB