Meets the Highest Demands

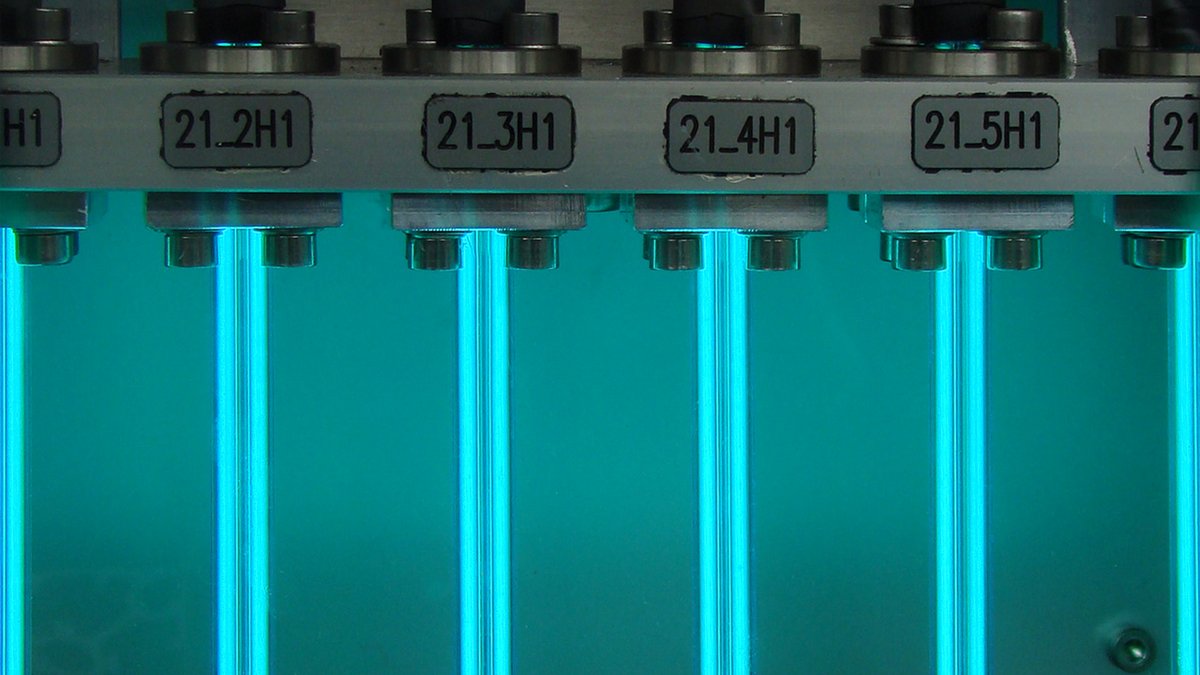

Highest precision, absolute cleanliness and strict compliance with customer specifications are the top priority in the manufacture of optical products. At the same time, various guidelines must be observed.

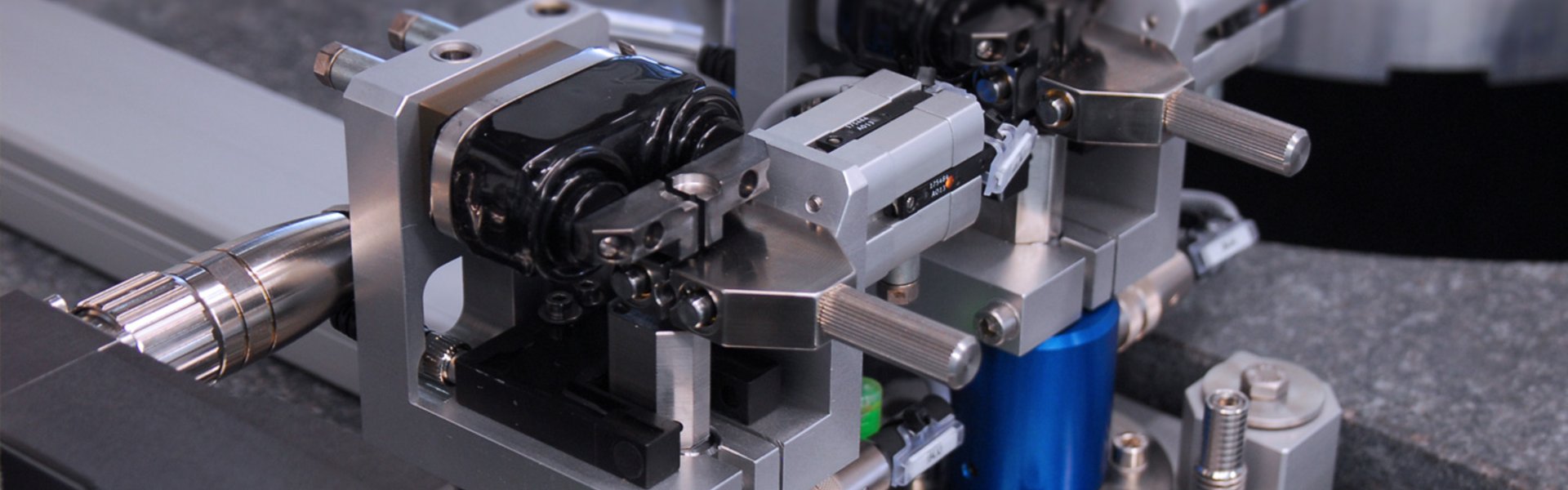

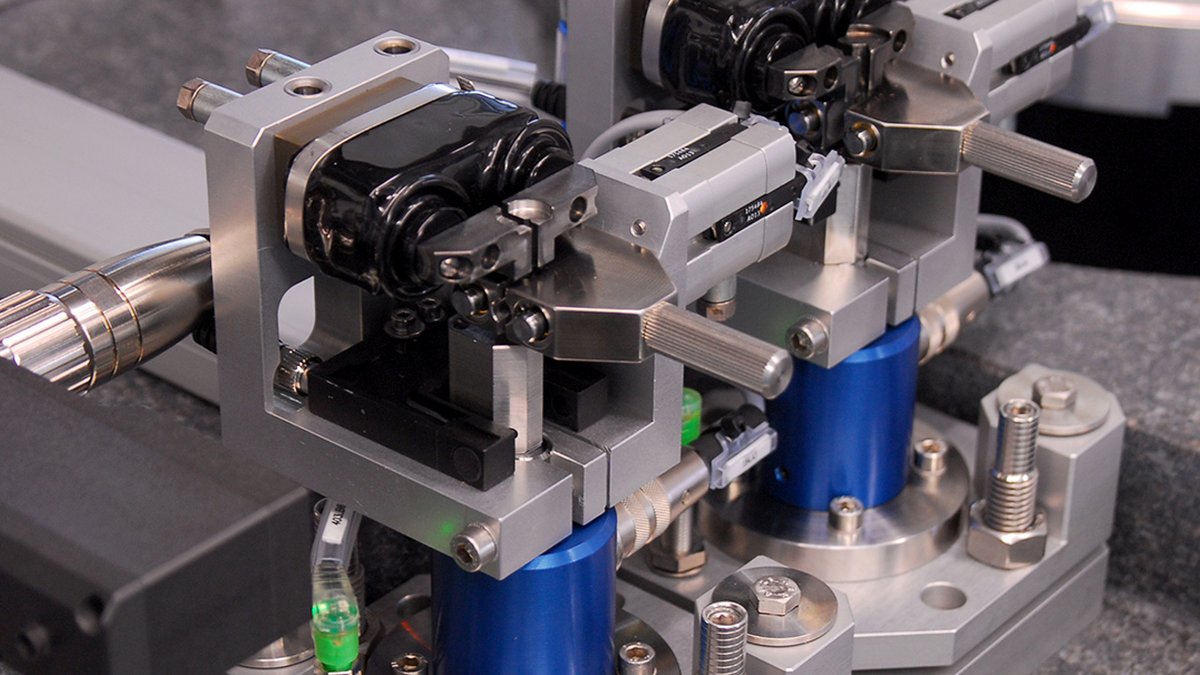

In order to meet the high demands on accuracy and reliability, BBS Automation systems only use components that have been specially developed for the requirements in this technical environment. By using machine frames made with high-strength hard stone, BBS Automation already defines a quasi industry standards .

Numerous projects in the field of optics are also being developed for use in cleanrooms. They can be built up and put into operation in our own clean room.

Manufacturing and Assembly Experience

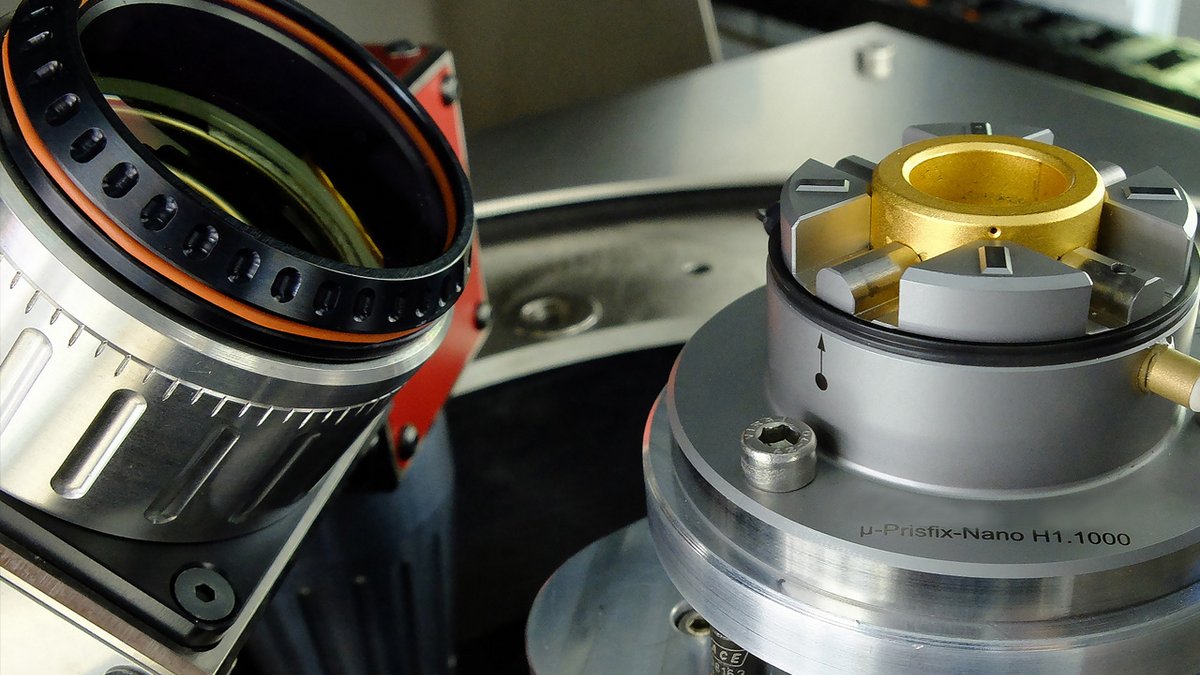

- Prisms and Filter Glasses

- Contact Lenses

- Assembly, Welding and Measuring of Precision Components

- Microdosing and Bonding

- Precision Mechanical Systems

- Sensor Production

- Camera Systems

Get in touch with our experts

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB