Foundry Technology and Automation

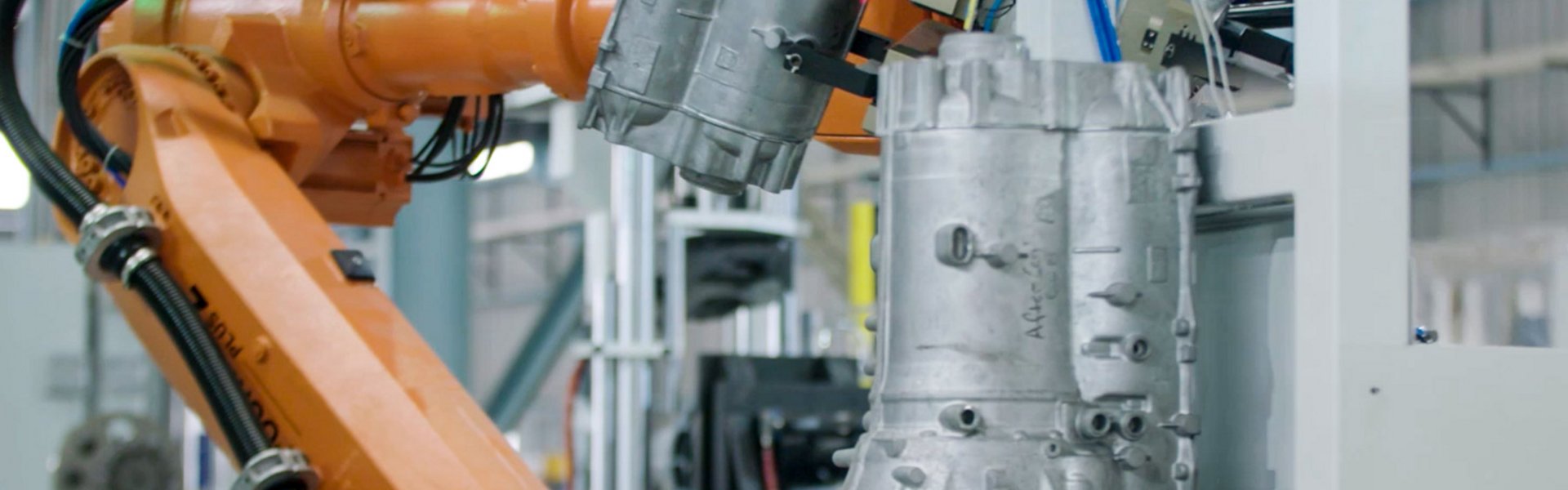

Traditional foundries constantly deal with the goal of efficiency, flexibility and work safety. BBS offers proven automation solutions along the entire foundry process chain.

BBS systems are developed for the challenging conditions of die casting production. Our low-maintenance and flexible foundry systems are specially designed for production under high loads at the highest temperatures in a dusty environment.

From automated Die Casting to Assembly

In high pressure die casting, BBS provides trimming machines, trimming tools, saw stations and other peripherals for integration in die casting automation.

In low-pressure and counter-pressure casting, BBS offers automatic casting lines and casting finishing lines, including casting machine loading and unloading, casting cooling, sand removal shaker, coding, trimming, sawing and drilling, flow detection, X-ray/CT inspection, etc.

In the field of gravity casting, BBS has automatic gravity casting production lines and automatic casting post-processing lines, including automatic casting, core setting, parts extraction, coding, cooling, sand removal shakers, saw blade, X-ray/CT inspection, etc.

For sand core production, BBS develops automatic assembly lines, including automatic core removal, core definition, core making, bonding, coating, casting and many more features.

Facts about Foundry Automation

- Wealth of experience in foundry automation, foundry operation, maintenance and casting process

- Full range of technology

- Flexible designs of machines allow quick adjustments for different requirements, essential for a comprehensive product portfolio

- Stable and robust machine structures

- Reliable machine principles

- High availability, fast cycle times and maximum throughput

Our Advantages

- Wide experience and various product range

- Global footprint of BBS

- Multilingualism of employees

- Tailored, customer-oriented solutions

- Optimized build times with 100% monitoring, reliability, quality

- Global project management and service support

- A key account team conducts each project

Get in touch with our experts

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

Pre-contractual information obligations Machine BBS Automation Hallbergmoos

PDF / 136.06 kB

Pre-contractual information obligations Machine BBS Automation Hallbergmoos

PDF / 136.06 kB

Pre-contractual information obligations teamsoft.TEST

PDF / 155.54 kB

Pre-contractual information obligations teamsoft.TEST

PDF / 155.54 kB

Pre-contractual information obligations teamsoft.RUN

PDF / 155.49 kB

Pre-contractual information obligations teamsoft.RUN

PDF / 155.49 kB

Pre-contractual information obligations teamsoft.HMI

PDF / 155.49 kB

Pre-contractual information obligations teamsoft.HMI

PDF / 155.49 kB