The Assurance for Safety and Quality Powered by BBS

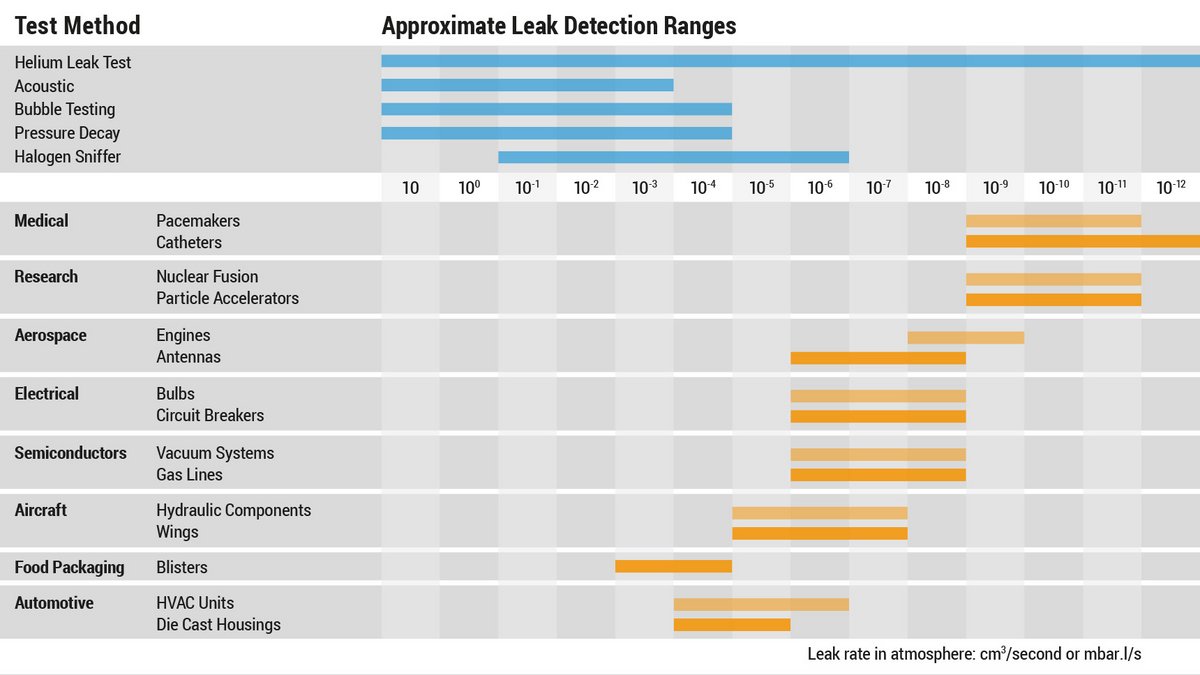

BBS’ highly sensitive leak detection and sniffing systems ensure that components assembled by our sophisticated manufacturing methods are leak-proof and sealed.

We analyze customer specifications and offer various methods to connect the leak detection system to other production equipment, from fully or semi-automated systems to a manual/batch version. No matter what your application or industry is, our integrated manufacturing and testing solutions will meet your requirements. Additionally, our special helium recovery systems help to reduce emissions and costs during production.

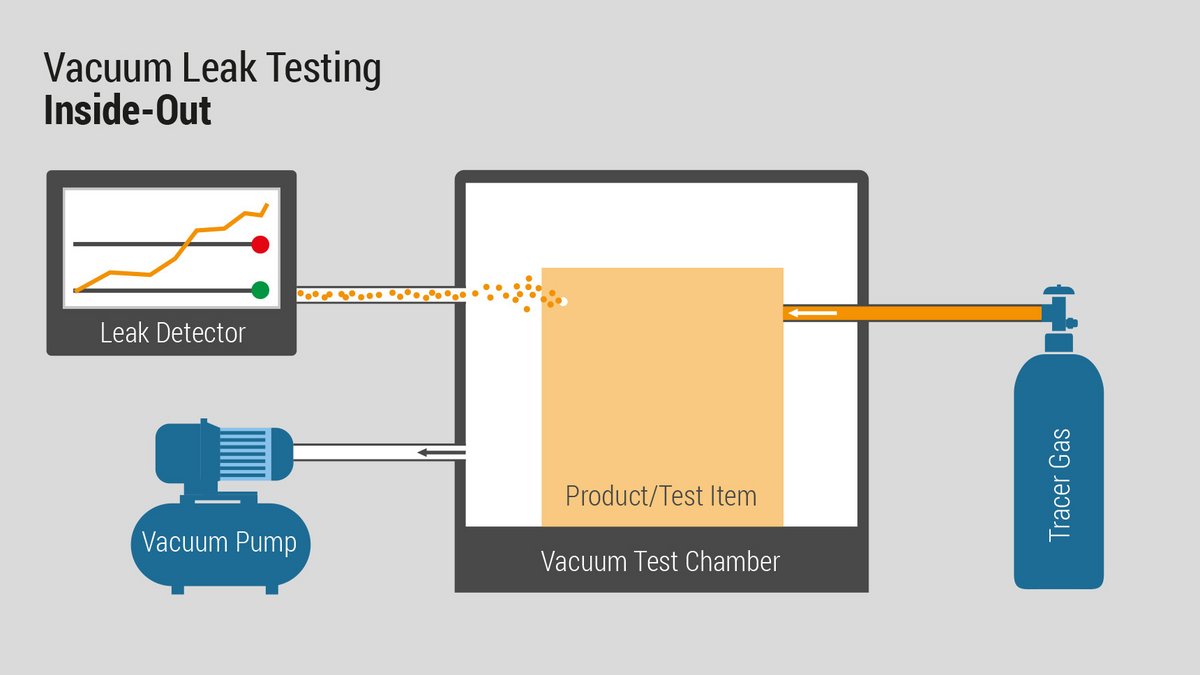

Process Technology Inside-Out

The flow takes place from inside the product outward, pressure inside the product is higher than the ambient pressure.

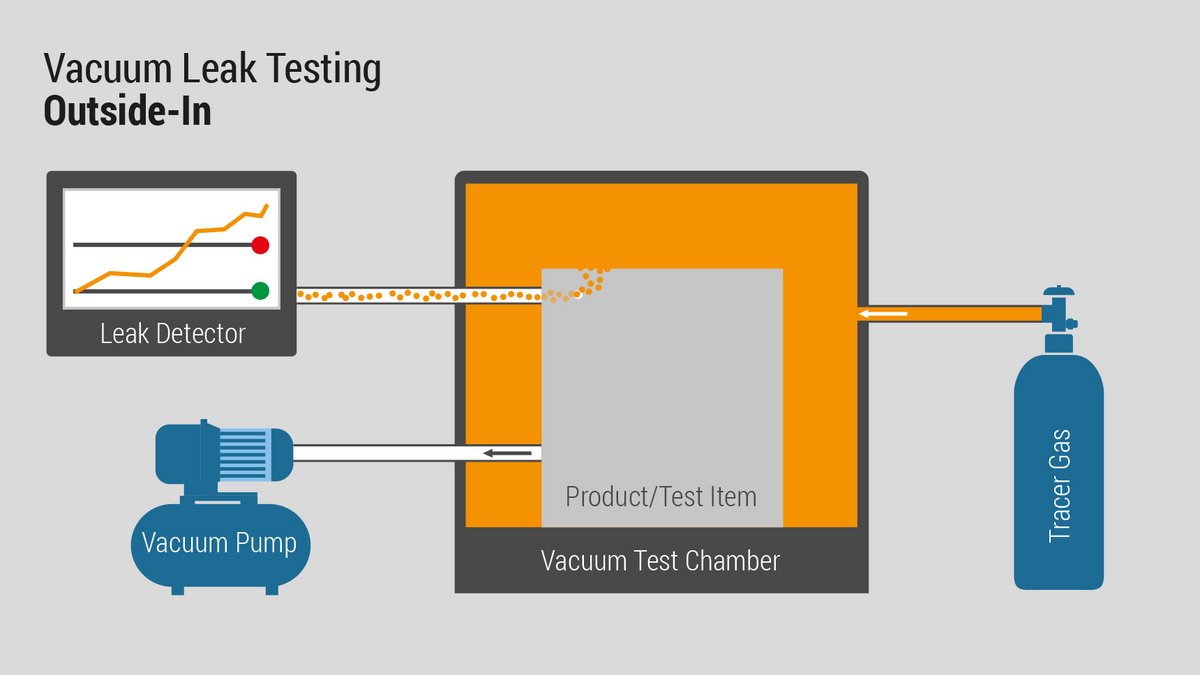

Process Technology Outside-in

The flow of tracer gas is into the product, pressure inside the product is less than ambient pressure.

Short facts about HLDS from BBS

- Ability to provide the customer with a total solution, from assembly to the testing process

- Customized and compact design

- Systems with highest sensitivity

- Single frame, stable and easy to relocate

- Automatic calibration

- Optional heating device to prevent moisture from affecting cycle time

- Two pumping lines (pre-vacuum and high vacuum)

- Dedicated filters for vacuum or high pressure line

- Built-in systems to locate leaking helium lines

- Automatic depollution with nitrogen

Our Advantages

- Wide experience and various product range

- Global footprint of BBS

- Multilingualism of employees

- Tailored, customer-oriented solutions

- Optimized build times with 100% monitoring, reliability, quality

- High productivity, operating 24/7

- Global project management and service support

- A key account team conducts each project

Get in touch with our experts

Headoffice

Would you like to contact BBS Automation online?

Then use our online contact form!

Downloads

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

TISAX® Assessment Scope SNR79P

PDF / 118.85 kB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Navigating ISO 11608 with Automated Equipment for Customised Pen and Autoinjector Testing - EN

PDF / 1.11 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Bonding Technologies for Injection Devices - EN

PDF / 3.2 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB

Industrialisation of Customisable Product Platforms in Life Sciences - EN

PDF / 1.25 MB