The Different Ways of Quality Assurance

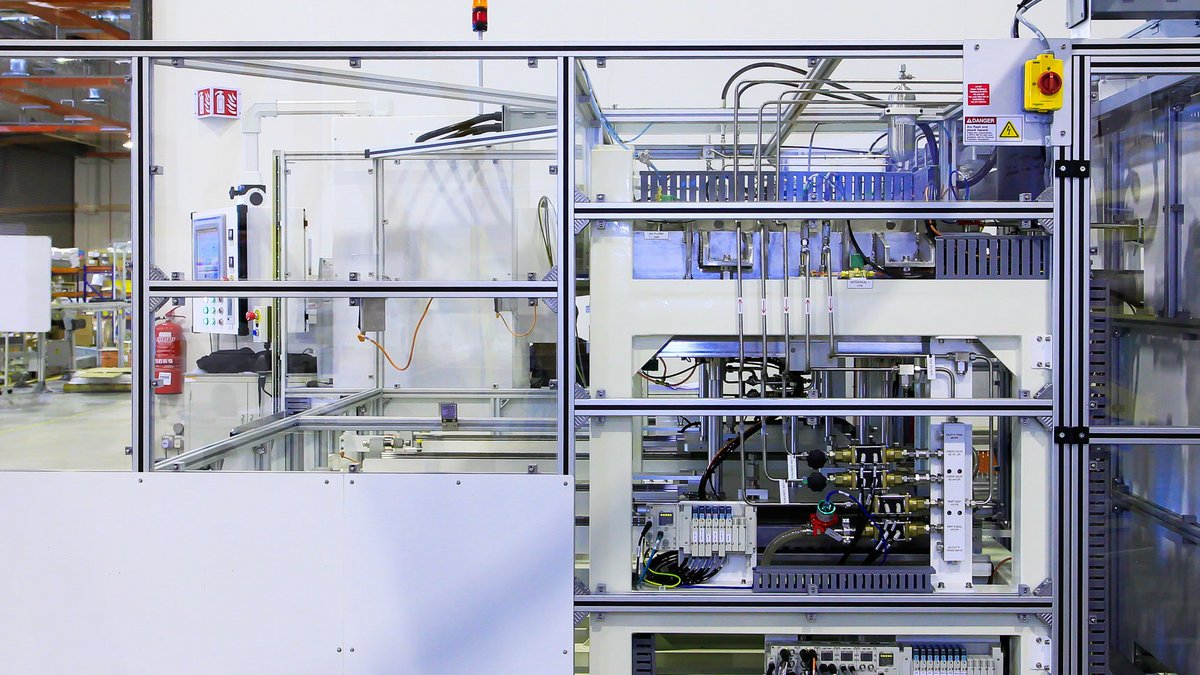

BBS’ highly sensitive leak detection and sniffing systems ensure that components assembled by our sophisticated manufacturing methods are leak-proof and sealed.

We analyze customer specifications and offer various methods to connect the leak detection system to other production equipment, from fully or semi-automated systems to a manual/batch version. No matter what your application or industry is, our integrated manufacturing and testing solutions will meet your requirements.

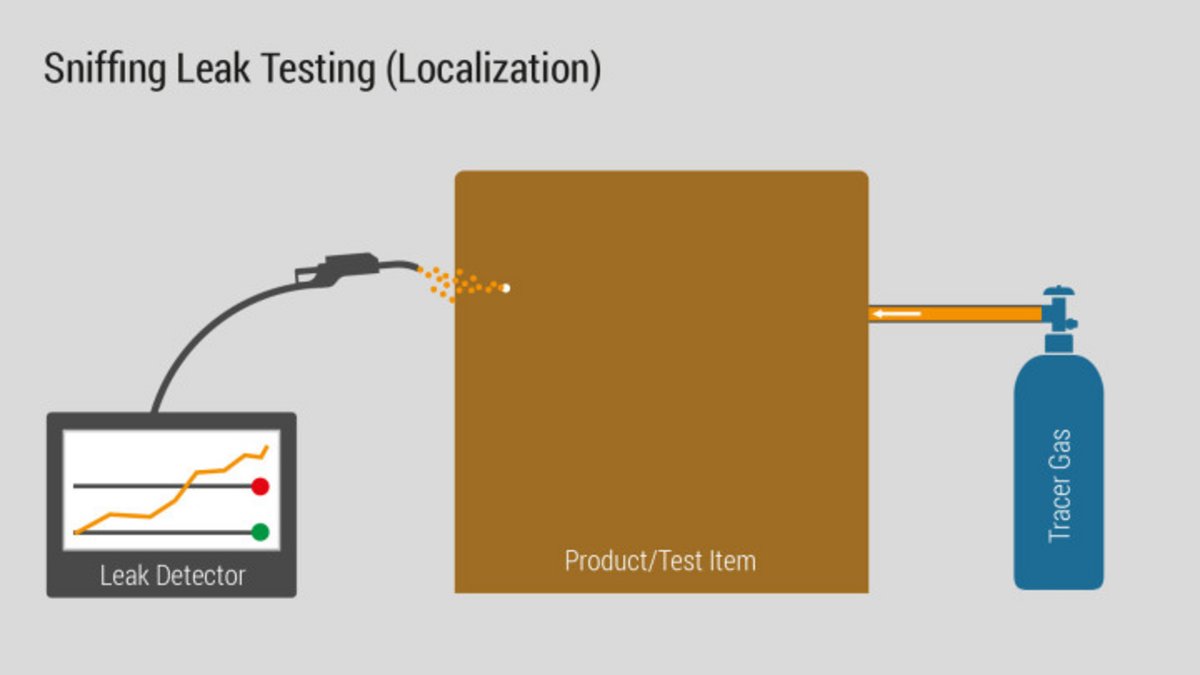

Sniffing Test

The product is filled with tracer gas. In case of leaks the tracer gas escapes through the leakage channel and is detected by a sniffer probe.

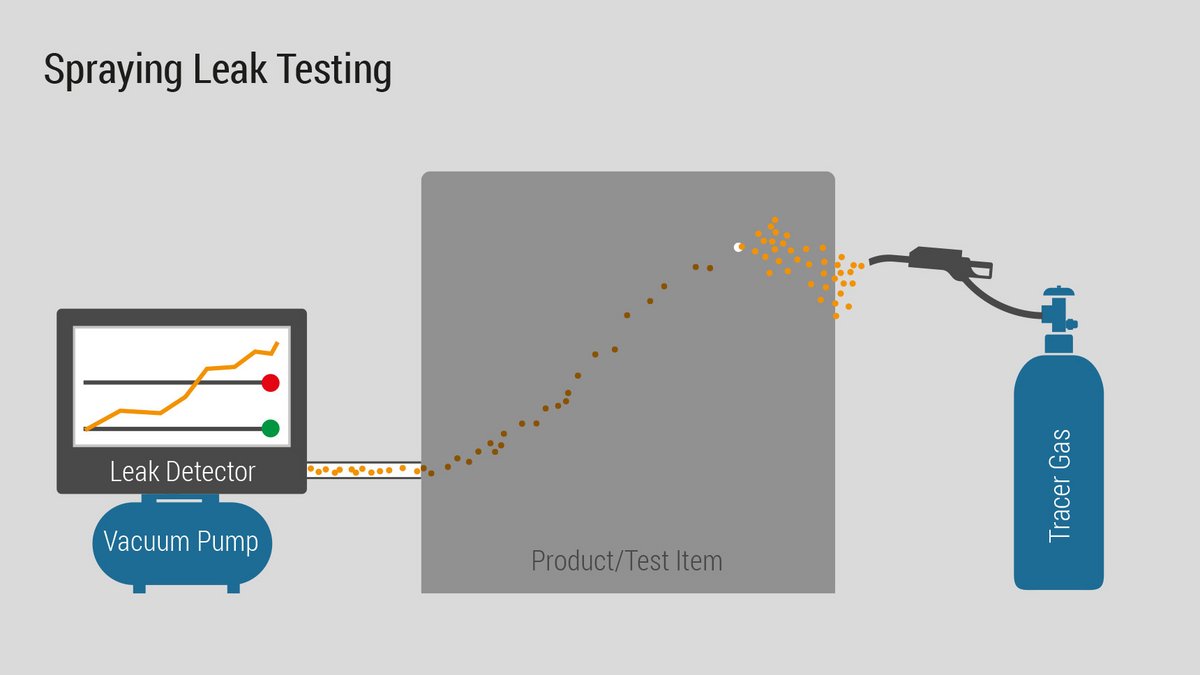

Spraying Test

First a vacuum is created in the product. The tracer gas is distributed over the product with a spray probe and can penetrate the leak.

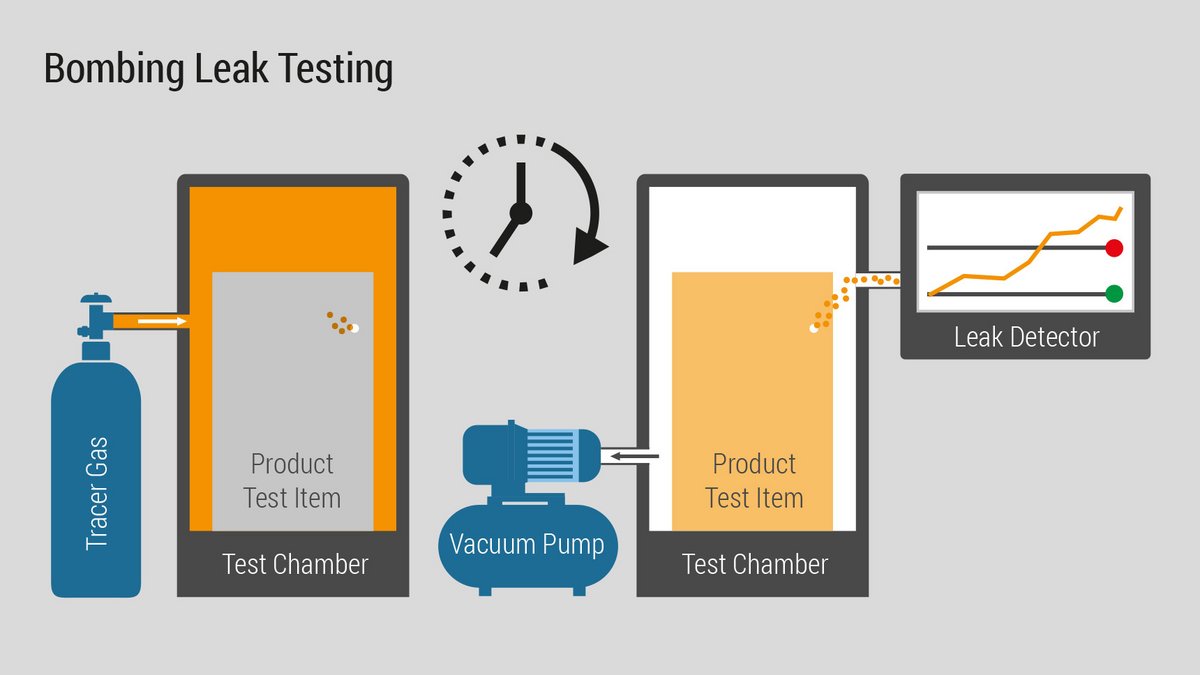

Bombing Test

The method is used for products that cannot be connected directly to a leak detector. The product is placed in a chamber containing pressurized helium. The helium penetrates into the product. The actual test then takes place in the vacuum chamber, to which a helium detector is connected.

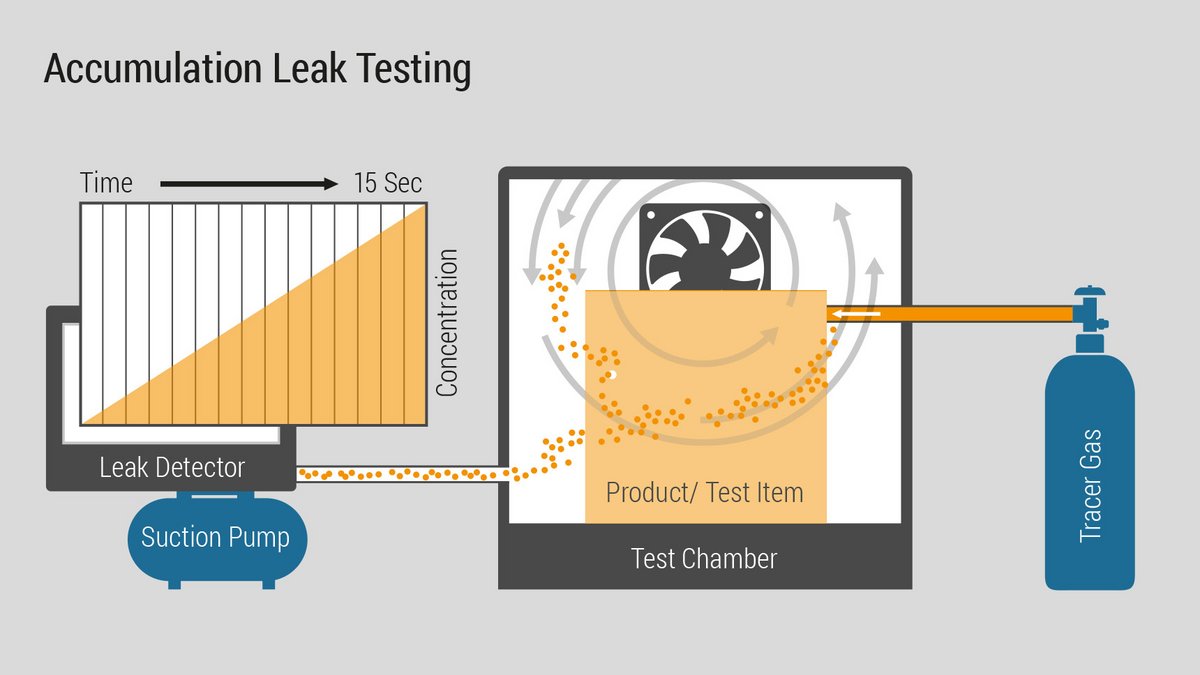

Accumulation Test

The product is placed in an accumulation chamber and filled with tracer gas. Gas which escapes through leaks is equally distributed throughout the chamber via fans. The leak detector measures the total leakage rate of the test item.

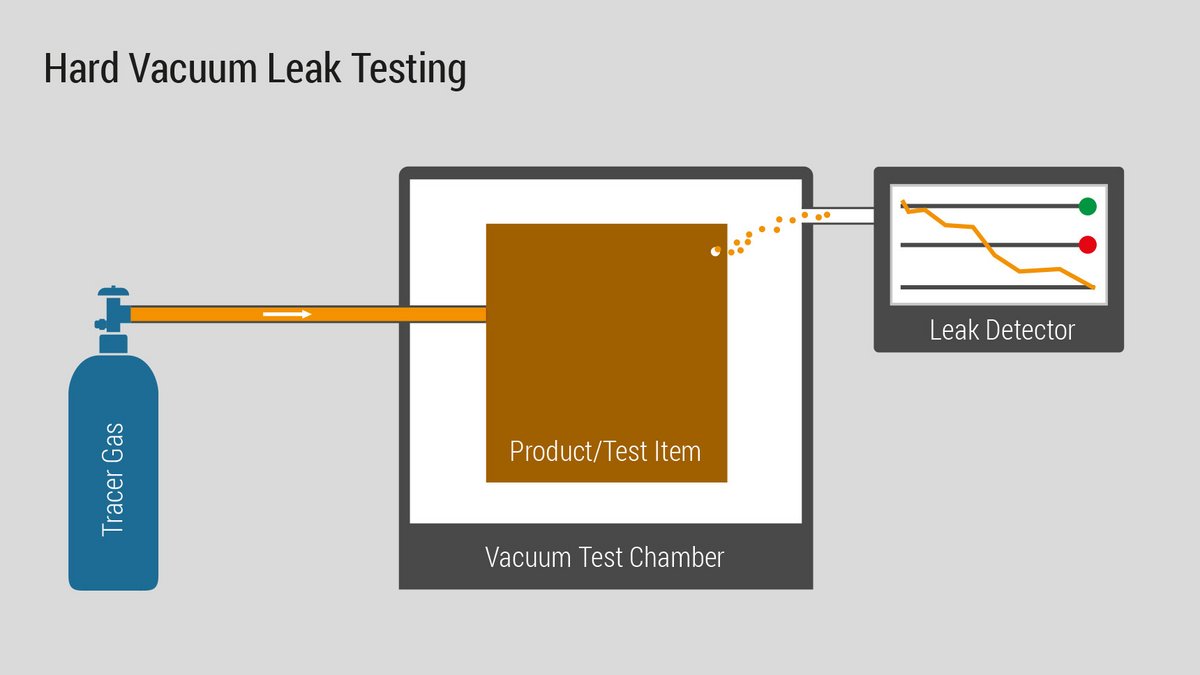

Hard Vacuum Leak Test

The product is filled with helium in an evacuated vacuum chamber. In case of a leak, the gas escapes through the leak and is measured by a helium leak detector which is connected to the vacuum chamber.

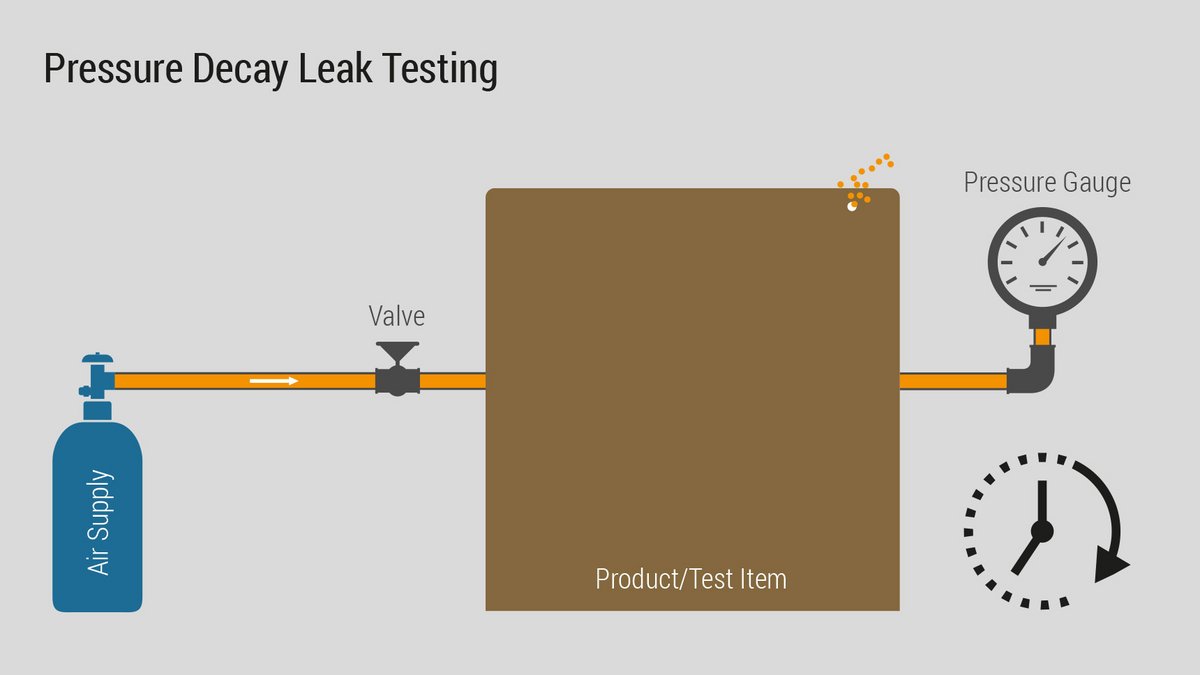

Pressure Decay Leak Test

The product is filled with air until it reaches its target pressure. The air supply is cut off to isolate the pressure. The pressure decay is measured over a specified period of time. In this way, the degree of leakage is calculated.

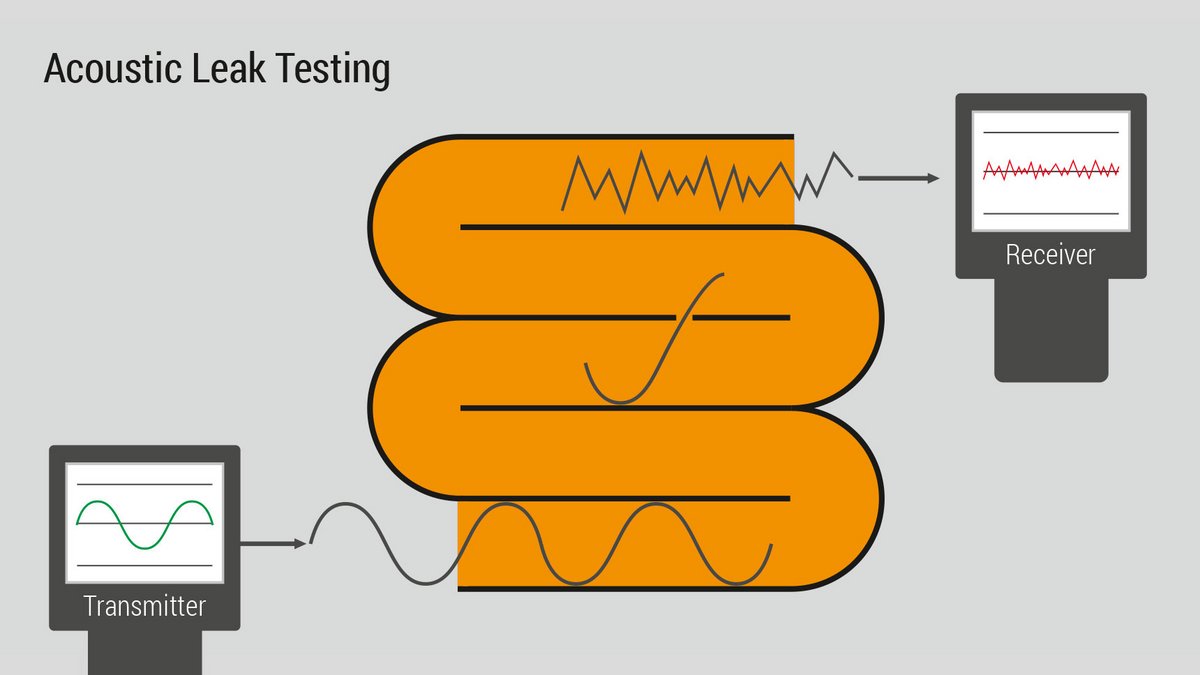

Acoustic Leak Testing

The test method is preferably used for pipe systems that cannot be accessed directly, for example because they are installed in a housing. Sound waves are sent through the test item by means of a transmitter. The sound waves recorded by the receiver are analyzed for characteristic changes in order to identify leaks.

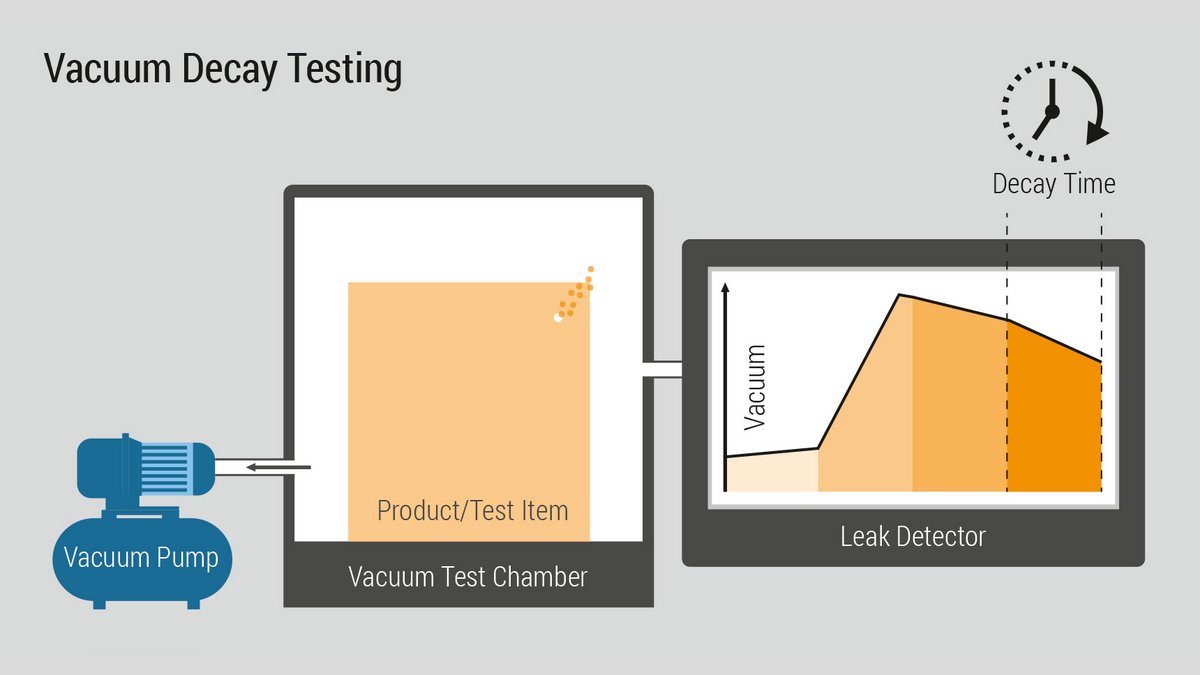

Vacuum Decay Testing

The test is an efficient test method for detecting very small leaks. The test item is located in a vacuum test chamber. The connected detector measures the vacuum level in the chamber over a certain period of time and determines the change of the vacuum level in case of a leak in the test item.

Downloads

Certificate ISO 14001 Sonthofen

PDF / 1.87 MB

Certificate ISO 14001 Sonthofen

PDF / 1.87 MB

Certificate ISO 45001 Sonthofen

PDF / 1.87 MB

Certificate ISO 45001 Sonthofen

PDF / 1.87 MB

Certificate ISO 9001 Sonthofen

PDF / 1.88 MB

Certificate ISO 9001 Sonthofen

PDF / 1.88 MB

Data Privacy Framework Policy BBS Chicago

PDF / 56.57 kB

Data Privacy Framework Policy BBS Chicago

PDF / 56.57 kB